![]()

CHAPTER 1

Market and Strategy

At the end of the chapter you will be able to:

- explain why verticalisation and supply chain management is so important for management today;

- explain what distribution channels exist and which members are active in the supply chain-network;

- name the three most important business drivers for brand label manufacturers and retailers;

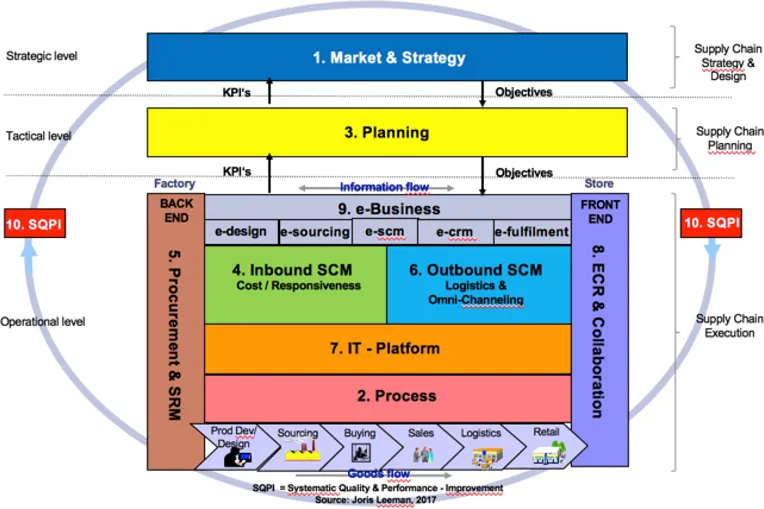

- provide a brief explanation of the supply chain-system - model and how to create a competitive advantage with it;

- name the most important strategic building blocks for the development of an end-to-end supply chain-system.

Case Faster fashion puts new pressure on supply chains

I can remember an audience of supply chain professionals left agog a few years ago, as they listened to Spanish academic José Luis Nueno explain how Zara can see an outfit on the catwalk in Paris – and have a version of it on the shelves of its stores 24 hours later. Of course, that level of performance is exceptional – but even the norm of a few weeks was way ahead of its competitors who were still designing seasonal collections months in advance. Since then “fast fashion” has become a key ingredient in the product offer for many apparel retailers as they have realigned supply chains to push the moment of production as close as possible to the moment of sale. But achieving this is tough and some major retailers are still struggling to match the industry’s best.

For example, in March 2015, the CEO of Gap, Art Peck, said in a magazine article that it was taking Gap up to three times as long as competitor such as Zara and H&M to get product ideas into the store. And when it published its 2015 annual report earlier this year, Gap said: “For fiscal 2016, our top objective is to improve sales performance through a more consistent, on-trend, product offering. To enable this, we have several product initiatives underway, and in addition, we plan to continue focus on our responsive supply chain and inventory management.”

But now, it seems, fashion is getting even faster. Next week Burberry will take the first step in a strategy that moves it away from its traditional four runway shows a year to just two, straight to consumer shows. CEO Christopher Bailey said its shows had been evolving to close the gap between when consumers could see collections on the runway and retail availability. “From live-streaming, to ordering straight from the runway, to live social media campaigns, this is the latest step in a creative process that will continue to evolve.” US designers Tommy Hilfiger and Tom Ford are also reported to be adopting “see-now, buy-now” strategies. Clearly, there are big wins to be had, but equally clearly, there are big implications for the supply chain. By definition, products have to be available immediately – no waiting to see how the collection is received. That means that the risks associated with a poorly performing line are going to be greater. So not only must supply chains be able to accommodate the increase in speed to market – they must also be more responsive and agile to deal with problems more quickly.

Source: M. Davies (red. 2016), ‘Faster fashion puts new pressure on supply chains’, Logistics & Supply Chain, 9/2016.

1.1 Strategy, verticalisation and supply chain management

1.1.1 Strategy

Succesful companies work according to a certain strategy. Such a strategy is composed of elements which enable to create a competitive advantage. The competitive advantage has to be visible for the customer or consumer: on one hand via the product or service, on the other hand via its process (service, quality, time, cost). The development, production and delivery of a product or service is comprised of several process steps within the supply chain. Very often these process steps are being organized by several companies, operating in different countries. Hence, they are increasingly dependent on each other within the supply chain. Companies collaborate. to maintain control. A specific form of strategic collaboration is verticalization. Verticalisation focuses on managing the supply chain based on a (planned) demand of the customer or consumer. Companies closely work together in planning, manufacturing and distribution of the product or service.

What is the situation in retailing?

The opening case made clear that retailers, like Zara, with a smart business strategy respond to the everly faster changing requirements of the consumer. To have the right products is not enough, as products with a high demand also need to be replenished timely. Next, information systems are needed to identify bestselling products, and organize product planning and digital coordination of the product deliveries. The processes and systems enable fulfillment of the requirements of the customers. However, not all products can be sold and delivered following a similar pattern. Certain products are available all-year-through and therefore need to be replenished during the year. Other products are fashion-driven and as a result are only for a short-time period available on the market. Very often replenishments are not possible given the short-time availability. The inventory risk of not being able to sell the product is for both example-products different: products which are available all-year-through (non seasonals) have less inventory risk compared to articles which are temporarily as a fashion-item on stock (seasonals). Therefore, the chosen product-strategy has a big influence on the inventory risk all members in the supply chain have. Moreover, the process-requirements are different too: non-seasonals have to be replenished very fast, which has demanding requirements for the different members in the supply chain. Articles which are only available for a limited time will be less frequently replenished and require less supply chain requirements. The chosen company strategy determines the level of coordination requirements with respect to processes and systems.

What is the situation in manufacturing?

A similar situation as described in retailing is applicable for a company operating within a manufacturing environment. Companies like ThyssenKrupp, ABB, Philips and Siemens very often engineer, manufacture and distribute products on a project-base, sometimes even tailor-made developed, produced and delivered. Just think of elevators, transformers for machines in a factory, medical equipment for a hospital. The final product (the project) is often a composition of products of suppliers, assembly of part of these products in one’s own product, and assembly and installation of all produts at the customer’s location turn-key. of the customer These types of projects are bound by quality, time, service and cost. Competitive rivalry is high and supply chain-performance of a timely project-installation is the key-factor. Most often these products are ‘make-to-order’ or even ‘engineer-to-order’, which means that also in the ‘make’-industry the supply chain is demand driven; like in retailing! The case upon the ‘make’-industry according to ING-Bank as shown at the end of this chapter confirms this line of reasoning.

Competitive strategies according to Treacy and Wiersema

Treacy and Wiersema differentiate three competitive strategies, which are based on the three generic competitive strategies of van Porter.1 Each strategy has a different emphasis on quality, time, service, and cost.

- Operational excellence-strategy (lowest possible cost).

This strategy is focused on reaching an optimal combination of price, quality and buying convenience which cannot be matched by its competition. Its emphasis is on low prices and standardized processes to be able to operate efficiently.

- Product leadership-strategy (best product.)

This strategy is focused on continuous (technological) innovation of the product assortment. Its emphasis is on product innovation and delivery of the the best product on the market.

- Customer intimacy-strategy (customer intimacy)

This strategy is focused on creating a close relationship with the customer by fulfilling its requirements: tailor-made services and mass customization. Tailor-made services are individually composed for the customer. Mass customization organizes tailor-made services for a group of specific customers. Its emphasis is on service, quality, quality and services during the overall process.

Toolbox 1.1:

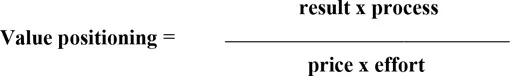

Value positioning-model of Treacy en Wiersema2

Treacy and Wiersema developed a value positioning-model based on which companies can determine how to realize a competitive advantage with four elements. It is a useful and practical model to easily find out the strategic focus of a company.

For example, the process is the experience of the booking of a train ticket and train journey itself. The product is the travel service from point A to B.

The two elements below the line are focusing on what the customer has to pay or has to do, in order to acquire the product/service. For example, the effort is what the customer has to do to purchase and receive the train ticket.

Based on the value positioning-model the company can choose with what strategic element to compete in order to realize a competitive advantage: via the final product (result), the process-experience, its price, or effort to acquire the product/service, or in a combination of these elements. Furthermore, the value positioning allows companies to compare their strategies. The three mentioned strategic directions – operational excellence, best product en customer intimacy – differ in the composition of the four value positioning elements.

Task: fill out the value positioning model for the three mentioned strategic directions. Evaluate what the essential differences are per strategy to create the competitiv...