- 890 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Fission Product Processes In Reactor Accidents

About this book

The Three Mile Island and Chernobyl nuclear incidents emphasized the need for the world-wide nuclear community to cooperate further and exchange the results of research in this field in the most open and effective manner. Recognizing the roles of heat and mass transfer in all aspects of fission-product behavior in sever reactor accidents, the Executive Committee of the International Centre for Heat and Mass Transfer organized a Seminar on Fission Product Transport Processes in Reactor Accidents. This book contains the eleven of the lectures and all the papers presented at the seminar along with four invited papers that were not presented and a summary of the closing session.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Fission Product Processes In Reactor Accidents by J. T. Rogers in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Energy. We have over one million books available in our catalogue for you to explore.

Information

Topic

Physical SciencesSubtopic

Energy1. INTRODUCTORY SESSION. OVERVIEW LECTURES

A Generic Overview of Severe Accident Phenomena

Safety and Reliability Directorate United Kingdom Atomic Energy Authority Wigshaw Lane, Culcheth Warrington WA3 4NE, UK

Atomic Energy of Canada Research Company Whiteshell Nuclear Research Establishment Pinawa, Manitoba, ROE 1L0 Canada

1. INTRODUCTION

In the course of the nuclear industry’s development, there has been a continuous evolution of safety philosophy and technology. From the beginning, the highest importance has been attached to safety and every effort has been made to foresee any possible incident having safety implications, and to make appropriate provision for the nuclear plant to survive without causing harm to the operators or to the public. This first emerged as the Maximum Credible Accident approach. Designers were required to show that they had identified all credible accidents, and to demonstrate for each one a satisfactory combination of procedures and engineered safety features (ESFs). The principal ESFs are automatic protection to shut the reactor down and a reliable means of decay heat removal.

That approach led to the concept of Design-Basis Accidents (DBA), which provide specifications for the performance required of the safety equipment and procedures. For such an approach to succeed, all DBA fault sequences must be identified and accurately analyzed. Furthermore, the ESFs must be extremely reliable. Given those conditions, analysis of a severe accident (conveniently defined as one that lies beyond the DBA envelope) did not form part of the safety case.

The DBA approach contains weaknesses that led to questions concerning completeness, understanding of postulated sequences, and equipment reliability. If an unforeseen accident should occur, or if a postulated accident develops in an unexpected way, or if an ESF fails, confidence that safety will be preserved is seriously undermined.

Containment is an ESF of particular significance. Some DBAs result in a limited release of radioactivity from the reactor’s primary circuit and containments are designed to prevent such activity from escaping. It was realized that the containment would also provide an additional means of protection against unforeseen incidents and for those that were inadequately covered, for whatever reasons, by other ESFs.

The accident at Three Mile Island in 19791, 2 provides a striking example of the effectiveness of containment. First, the sequence-oriented safety strategy, for a combination of reasons, led to a failure to intercept successfully what should have been a minor incident. Second, although the reactor was virtually destroyed, the containment successfully prevented any significant harm to plant personnel or the public.

The intense debate that followed the TMI-2 accident led to a much clearer appreciation of safety strategy in general and severe accidents in particular. An important consequence was a more realistic analysis of ESF reliability. Of more significance to this seminar is a recognition of two important features. First, even if an incident progresses beyond the DBA, there is a useful margin available in the ability of the ESFs to cope with demands well in excess of those for which they are designed. Second, to exploit that capability, it is necessary to adopt a flexible, symptom-oriented approach to accident management. A corollary of that is the need for a high degree of generic phenomenological understanding that needs to be disseminated appropriately among all plant personnel who would play a part in controlling a severe accident. These questions are addressed in greater depth in this session.

Progression beyond the DBA necessarily entails a divergence from the well-defined conditions of the design basis. In the early stages, with virtually undisturbed geometry, it is possible to analyze the course of events with some precision and confidence. Increasingly, as conditions change, the range of possible events grows and with it the difficulty of further prediction. Moreover, the relevant phenomena interact with each other and cannot properly be treated in isolation. The physical and chemical conditions are beyond those encountered in normal plant conditions and are correspondingly difficult to reproduce and study.

The only practicable way to deal with this problem is a combined strategy of studying separate effects and developing, in parallel, sophisticated models that enable accident progression to be calculated, taking into account the interdependence of the relevant phenomena. The separate-effects studies produce data and confirm the fundamental scientific modelling, whilst the codes enable that understanding to be applied to specific plants and accidents.3

Because of the number and range of parameters to be embraced, it is not practicable to reproduce experimentally all the possible accident sequences that need to be addressed. Such experiments are expensive and extremely time-consuming to set up and interpret. Nevertheless, there is a growing stock of integral experiments that are sufficiently close to the conditions of interest to provide a check on the validity of the computer models. The models can then be used to evaluate risks and countermeasures in relation to severe accidents. It is important to recognize that, since exceeding the DBA conditions is a very low probability event, it may not be necessary to achieve the same standard of qualification required within the design basis.

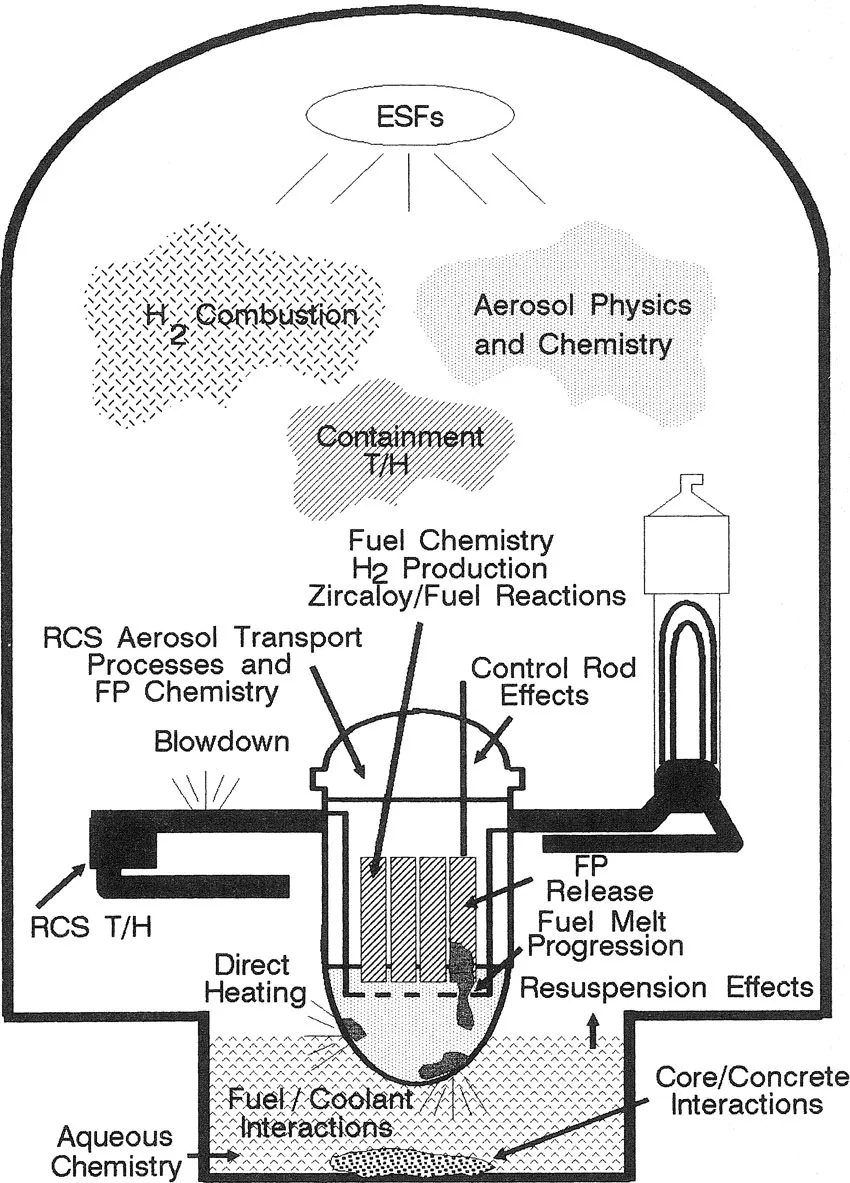

In what follows, we summarize severe reactor accident phenomena and point out some of the complexities associated with them. Figure 1 is an overview of the various processes that may occur during a severe accident in a PWR.

2. IN-CORE/VESSEL PHENOMENA

2.1 Core Damage Progression

An incident becomes a severe accident when it is no longer possible to cool the fuel by normal means. The first response will be to attempt to maintain cooling by whatever means is available, but such attempts need to be guided by an understanding of how core damage may develop. If the attempts fail, the effects of further damage and attempts to mitigate those effects will also depend on the details of damage progression.

The initial heating of the fuel is not difficult to predict, at least for as long as the original geometry is retained. The codes used in the design basis will adequately represent the thermal-hydraulics and the temperature distribution in the core. The source of heat will be fission product decay within the fuel, with an additional term arising from the oxidation of Zircaloy cladding as the temperature rises.

The first major problem is assessing when and how the core geometry will alter significantly. The melting points of the individual materials within the core as designed are well known, but chemical changes, such as oxidation by steam and eutectic formation between neighbouring materials, radically affect the composition and properties of the different components.

The oxidation of Zircaloy depends on the availability of steam and, below the Zircaloy surface, on solid-state diffusion of oxygen, which is the determining process at that stage. Unoxidized Zircaloy will melt at about 2050 K and UO2 at 3100 K. However, the relocation under gravity of an overheated fuel pin depends on the detailed history of the heating process. At slow heating rates (up to 0.5 K/s), the fuel cladding will be completely oxidized to ZrO2 before reaching the melting point of Zircaloy. At heating rates above 5 K/s, the cladding will start to melt when there is only a thin shell of ZrO2, which will be too weak to prevent relocation of the cladding. For intermediate rates, the oxidized cladding may have enough strength to hold the molten Zircaloy in place for a time while it begins to attack, by chemical dissolution, both the solid UO2 and ZrO2.

A further complicating factor arises from the control rods. In a PWR the silver-indium-cadmium absorber material melts at 1100 K, so it will be molten when the stainless steel cladding fails, probably by localized eutectic interaction where it contacts the Zircaloy of the guide tube. The relocated liquid alloy would then become free to attack Zircaloy cladding and accelerate the propagation of such damage even at temperatures as low as 1500 K.

Similar processes would occur in boiling water reactors (BWRs), where boron carbide absorber will rapidly attack stainless steel cladding at 1500 K. Alumina-boron carbide may be used, clad in Zircaloy, as a burnable poison. A strong interaction will occur at 1750 K, resulting rapidly in a liquid phase, which will in turn produce a liquid phase in both UO2 and ZrO2 at temperatures above 2200 K.

Thus, a simplistic model postulating a single core-slumping temperature is quite inappropriate. As regions melt, or become too weak to support themselves, their relocation must be considered realistically, recognizing that some of the liquid phases, such as those incorporating absorber material, will be extremely mobile and will resolidify only at extremely low (in the context of overheated cores) temperatures. Moreover, effects will be highly localized (e.g., near control-rod positions) and may result in opening up chimneys through the core, with marked implications for the supply of steam.

It can be seen that the core-melt progression is extremely complex and will occur in different locations in different ways. Material will tend to migrate downwards by a series of cycles of overheating, melting, cooling and resolidifying. Each cycle is likely to change the conditions governing the course of the next cycle, and it is clear that the uncertainties multiply rapidly as the process advances. The phenomena are in principle reasonably well understood and provide a good basis for developing a strategy for severe accident management, but it is unlikely that precise mechanistic descriptions of specific accidents will be possible for some years, if ever.

2.2 Fuel-Coolant Interaction

The phenomenon of vapor explosions has long presented intractable problems, particularly in the foundry and paper-making industries. Vapor explosions sometimes occur when hot molten material in bulk is quenched in a quantity of vaporizable liquid. However, more often than not, the transfer of heat between the materials is effected comparatively inocuously. Enormous efforts have gone into seeking a reliable explanation of the phenomenon, with only partial success.

Simple thermodynamic considerations show that the proportions in which the two fluids are mixed are crucial. A large excess of water could absorb all the available heat without necessarily producing any steam at all. Very limited quantities of water would reach very high temperatures, but the damage potential would be limited by the volume of steam that could be formed. Maximum conversion of heat to mechanical energy occurs when the volumes of interacting materials are roughly equal. Very damaging events have occurred, irrespective of the initial proportions, in which the components become rapidly mixed in approximately equal proportions by volume and on such a fine geometrical scale that vapor is formed with explosive violence. Because of the obvious relevance to severe reactor accidents, in which substantial quantities of molten fuel may fall into pools of coolant, the nuclear industry has devoted extensive efforts to understand how such explosions occur.

It is found helpful to treat the process in 4 stages:

1. Coarse mixing. In this stage the fuel is dispersed in the form of irregular drops, of perhaps a centimetre or so in size, in a metastable configuration. If violent boiling occurs on first contact, the materials are prevented from interpenetrating. It is likely that the metastable state consists of a stable vapor film surrounding each drop that limits heat transfer.

2. Triggering. The equilibrium is then disturbed by a trigger. This may be an applied pressure pulse or it may occur spontaneously. Experiments have shown triggering taking place when a drop wanders into a region confined by solid surfaces, such as a corner of the experimental vessel. The precise nature of the process is not at all understood, but it is probably the local collapse of the vapor film, resulting in a small-scale interaction that causes a pressure pulse.

3. Propagation. This stage is analogous to detonation of a chemical explosive and is set off by the trigger. It produces a self-sustaining wave that advances through the coarse mixture, causing fine fragmentation of the coarse drops. Heat transfer from the fine fragments supplies energy for maintaining the progress of the wave. Thus, extremely rapid heat transfer is brought about in a rapid coherent way. The precise mechanism for this self-propagating fragmentation wave is not completely understood, but there is impressive experimental evidence for its existence.

4. Expansion. The mixture of fuel, steam and water expands in this stage as an energetic source of pressure capable of producing great damage.

This division into four stages is an approximation to physical reality. In fact, the four stages are not entirely separate and each can ...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- 1. Introductory Session. Overview Lectures

- 2. Fuel Behavior and Fission Product Release

- 3. Transport Phenomena in the Reactor Coolant System

- 4. Transport Into Containment

- 5. Containment Transport Phenomena

- 6. The Accidents at Three Mile Island and Chernobyl

- 7. Closing Session

- Index