- 300 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This book provides a practical introduction to dynamic and positive displacement compressors, including compressor performance, operation, and problem awareness. In reading this book readers will learn what is needed to select, operate, and troubleshoot compressors.Complete with real-lifecase histories, the book demonstrates investigative techniques foridentifying and isolatingvarious contributing causes, includingdesign deficiencies, manufacturing defects, adverse environmental conditions, operating errors, and intentional or unintentional changes of the machinery process that usually precedefailure.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Introduction

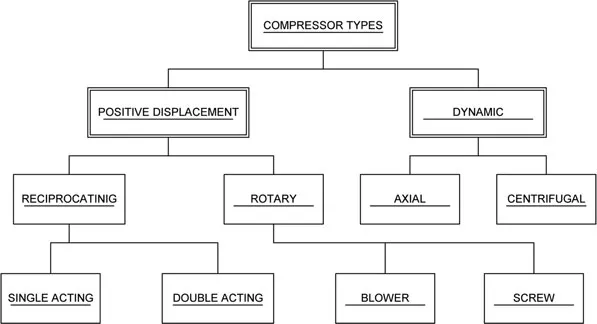

HISTORY

The history of compressors is as varied as are the different types of compressors. Therefore it is fitting that we first identify the different types of compressors. As shown in Chart 1-1, compressors fall into two separate and distinct categories: dynamic and positive displacement.

Somewhere in antiquity the bellows was developed to increase flow into a furnace in order to stoke or increase furnace heat. This was necessary to smelt ores of copper, tin, lead and iron. This led the way to numerous other inventions of tools and weapons.

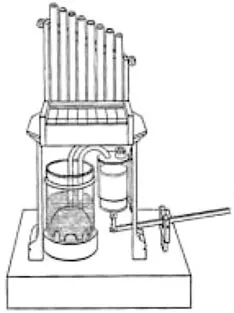

One of the earliest recorded uses of compressed gas (air) dates back to 3rd century B.C. This early use of compressed air was the “water organ.” The invention of the “water organ” is commonly credited to Ctesibius of Alexandria1. The concept was further improved by Hero of Alexandria (also noted for describing the principles of expanding steam to convert steam power to shaft power).

The water organ consisted of a water pump, a chamber partly filled with air and water, a row of pipes on top (organ pipes) of various diameters and lengths plus connecting tubing and valves. By pumping water into the water/air chamber the air becomes compressed. Than by opening valves to specific organ pipes the desired musical sound is created.

Ctesibius also developed the positive displacement cylinder and piston to move water.

It was not until the late 19th century that many of these ideas were turned into working hardware.

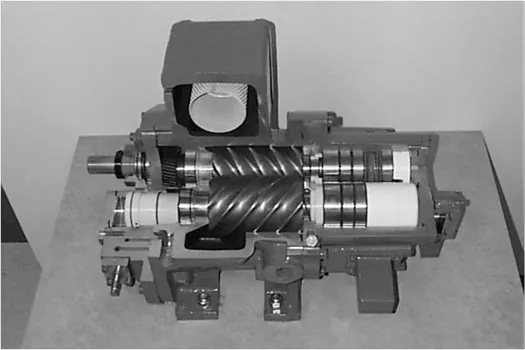

In the 1850s, while trying to find a replacement for the water wheel at their family’s woolen mill, Philander and Francis Roots devised what has come to be known as the Roots blower3. Their design consisted of a pair of figure-eight impellers rotating in opposite directions. While some Europeans were simultaneously experimenting with this design, the Roots brothers perfected the design and put it into large-scale production.

It is not surprising that other compressor designs followed power-producing designs. For example, the reciprocating engine concept easily transfers to the reciprocating compressor.

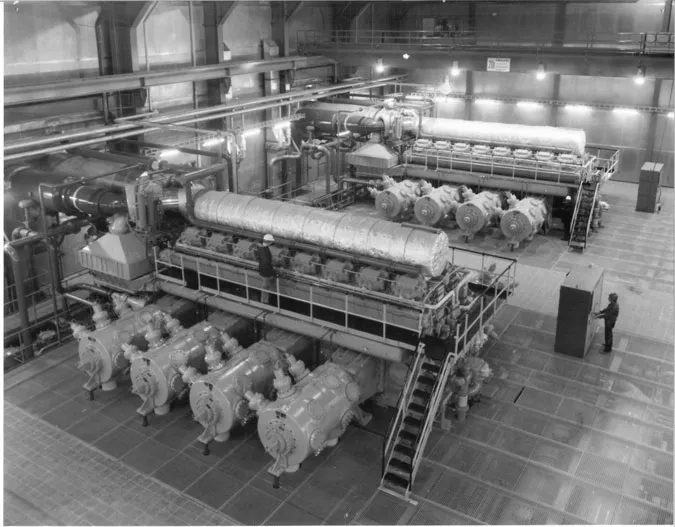

The integral-engine-compressor is a good example as its design utilizes one main shaft connected to both the power cylinders and the compression cylinders. The form and function of the compressor cylinders are the same whether it is configured as an integral engine-compressor or a separable-compressor driven by an electric motor, gas engine or turbine.

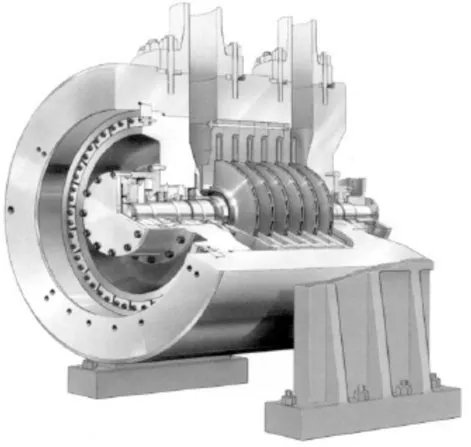

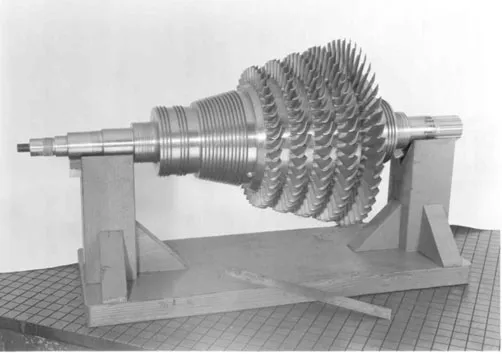

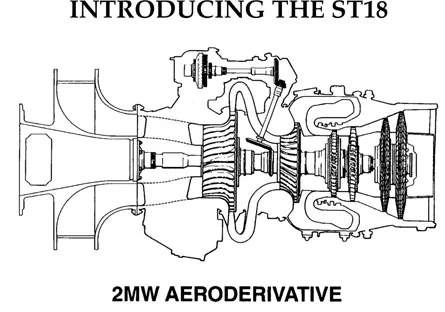

Other examples are the centrifugal compressor, (Figure 1-4) the turbo-expander, the axial compressor, and the axial turbine (Figure 1-5 and 1-6).

In 1808 John Dumball envisioned a multi-stage axial compressor. Unfortunately his idea consisted only of moving blades without stationary airfoils to turn the flow into each succeeding stage.4,5,6

Not until 1872 did Dr. Franz Stolze combine the ideas of John Barber and John Dumball to develop the first axial compressor driven by an axial turbine. Due to a lack of funds, he did not build his machine until 1900. Dr. Stolze’s design consisted of a multi-stage axial flow compressor, a single combustion chamber, a multi-stage axial turbine, and a regenerator utilizing exhaust gases to heat the compressor discharge gas. This unit was tested between 1900 and 1904, but never ran successfully.

Operating conditions have a significant impact on compressor selection and compressor performance. The influences of pressure, temperature, molecular weight, specific heat ratio, compression ratio, speed, vane position, volume bottles, loaders and unloaders, etc. are addressed in this book. These conditions impact compressor capacity and therefore the compressor selection. They also impact the compressor efficiency. Flexibility in selection is still possible to some extent as compressors can be operated in parallel and series modes. For example, to achieve higher pressures multiple compressors can be configured in series whereby the discharge of one compressor feeds directly into the suction of a second compressor, etc. Likewise, to achieve higher flows multiple compressors can be configured in parallel whereby the suction of each compressor is manifolded together and the discharge of each compressor is also manifolded together.

Different methods of throughput control are addressed in Chapter 5, such as, discharge throttling, suction throttling, guide vane positioning, volume bottles, suction valve unloaders and speed control; and how each of these control methods effects compressor life.

This book discusses different compressors; how they operate and how they are controlled. Since the cost of process downtime and damage to a compressor can range from thousands to millions of dollars; the types of failures that can occur and how to avoid these failures is also addressed in this book.

In view of the fact that the most destructive event in a dynamic compressor is surge, compressor surge will be defined and discussed in detail. Also discussed are the various types of instrumentation (controllers, valves, pressure and temperature transmitters, etc..) available and which are most suitable in controlling surge. Destructive modes of other compressors are also addressed.

A few algorithms are presented, primarily in Chapters 4 and 7, to help demonstrate interactions of pressure, temperature and quantify results, but their understanding is not essential to the selection of the proper control scheme and instrumentation. The reader should not be intimidated by these algorithms as their understanding will open up a broader appreciation of how the compressor works.

Footnotes

1 A History of Mechanical Inventions, Abbott Payton Usher. This Dover edit...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Preface

- Acknowledgements

- Chapter 1—Introduction

- Chapter 2—General Compressor Theory

- Chapter 3—Compressor Types

- Chapter 4—Effect of Operating Conditions

- Chapter 5—Throughput Control

- Chapter 6—Description of Surge

- Chapter 7—Surge Control

- Chapter 8—Vibration

- Chapter 9—Valve Requirements

- Chapter 10—Instrument Requirements

- Chapter 11—Detectable Problems

- Chapter 12—Controlling Reciprocatng and Centrifugal Compressors in Identical Processes

- Chapter 13—Optimization & Revitalization of Existing Reciprocating Compression Assets

- Chapter 14—Piston Rod Run-out is a Key Criterion for Recip Compressors

- Chapter 15—Effect of Pulsation Bottle Design on the Performance of a Modern Low-speed Gas Transmission Compressor Piston

- Chapter 16—Resolution of a Compressor Valve Failure: A Case Study

- Appendix

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Compressor Handbook by Anthony Giampaolo in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Thermodynamics. We have over one million books available in our catalogue for you to explore.