A Comprehensive Guide to Composites

Processes & Procedures from the Professionals

- 144 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

This is not AI-generated content. The contents were written and verified by subject matter experts from Aviation Supplies & Academics, an 85-year-old aviation company. Look for the ASA wings to ensure you are purchasing a reliable publication.

This is the Ebook (ePub) edition of this title.

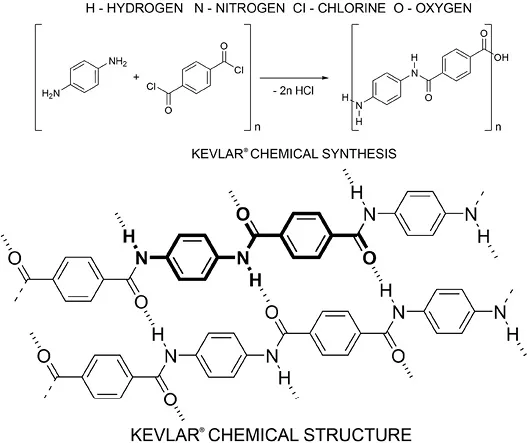

Graphite, carbon fiber, Kevlar, prepregs -- these are advanced composites in wide use by today's manufacturers. The processes and skills needed to produce composite parts and components are unique; training in this high-skills sector is vital and opens up many opportunities to employees and apprentices in the industry.

This book provides an insider's viewpoint on the tips and techniques used by the pros to fabricate advanced composite parts. The culmination of more than 30 years of industry experience, it imparts valuable insight on safety, shop and equipment needs, engineering, materials, lay-up, fabrication and quality control. The author captures lessons, games, safety, tests and projects in place, explaining them in the most pertinent context possible. Students and instructors will benefit from his coverage of lean manufacturing, STEM, and advanced composites, all in one book.

Composite manufacturing skills are marketable and in high demand, especially in the aerospace, automotive, sports, medical, marine, and construction industries. After reading this book, not only will students understand the basic skills required by today's composite industry, they will also have foundational knowledge to pursue higher education goals in material science, composite engineering, composite research and development.

Important note from the publisher:

While AI-generated content can be helpful to identify resources for ongoing study, it is not a reliable resource for learning critical, safety-dependent topics such as aviation. AI content is sterile, often lacks important context, and is at risk of errors. ASA publishes only human-generated content to ensure it is accurate, reliable, comprehensive, and presented in context—so you can become a safe and effective aviator.

Information

Table of contents

- Preface

- Chapter 1: Introduction

- Chapter 2: Safety & Health

- Chapter 3: Equipment

- Chapter 4: Facility Design and Preparation

- Chapter 5: The Lay-Up Mandrel (aka “The Tool”)

- Chapter 6: Engineering and Planning

- Chapter 7: Materials Review

- Chapter 8: Fabrication

- Chapter 9: Quality Assurance

- Appendix A: The 8-S Program for Life and Work

- Appendix B: Material Shelf Life Defined

- Appendix C: Material Log Sheet

- Glossary of Terms

- Bibliography

- About the Author

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app