eBook - ePub

Physical Asset Management for the Executive Caution

Don't Read This If You Are on an Airplane

- 128 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Physical Asset Management for the Executive Caution

Don't Read This If You Are on an Airplane

About this book

Proper management of physical assets remains the single largest business improvement opportunity in the 21st Century. The size of the asset management industry in the USA, alone, was $1.2 Trillion. Of that, $750 Billion was the direct cost of poor physical asset maintenance and management.

In this book, Dr. Howard W Penrose discusses the necessary strategies to take advantage of this last frontier in business improvement. Determine where you stand by asking yourself these questions: The next time you get on that elevator or airplane, what if they are maintaining it the same way you maintain your facilities and production equipment? Would you want to ride?

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Physical Asset Management for the Executive Caution by Howard W. Penrose in PDF and/or ePUB format, as well as other popular books in Commerce & Stratégie commerciale. We have over one million books available in our catalogue for you to explore.

Information

Topic

CommerceSubtopic

Stratégie commercialeChapter 1

The Culture and Impact of Maintenance

The common practice for R&M budget management is to continue to address the issue by reducing the budget each year. By the end of the year, the budget has been exceeded significantly and the maintenance manager is brought on the carpet.

At first I tried to understand why we in the R&M industry were so masochistic. The maintenance staff works hard, usually end up putting in overtime on weekends, holidays and have vacations cut short or cancelled. When I left the ‘floor’ and started into R&M (including energy) research I began to see the reason. Working in the boardroom, conference room, teaching and training have been exciting, but there is no greater ‘rush’ than solving a machine problem and getting production equipment back up and running. You see immediate results from your work and the satisfaction is addictive. Moreover, when equipment goes down and production is at a standstill, you get attention and may even be rewarded for how quickly you get the equipment back up and operating.

The effect has been referred to as ‘Hero Maintenance.’ It is often described as people not seeing the maintenance staff until something fails. Then all of a sudden these people come out of the woodwork with magic tools and the equipment starts, everything goes back to normal with the only comment being, ‘who were those masked men?’

The challenge is that when R&M works properly, this type of situation should very rarely occur. In fact, improper maintenance is one of the issues that has brought us to these crossroads to begin with. When equipment was built like tanks, was very reliable and our workforce extremely confident, equipment failures did occur, but rarely. We maintained everything, whether the machines or structures were critical or not, because it made sense and cost was a minor issue. Everything else we just lived with.

In the 1980’s, the primary focus within business became ways and means to reduce the cost of business, throughput and breaking production bottlenecks. The concept was to trim the fat of these companies by trying to eliminate unnecessary tasks and the reduction of personnel. However, a lack of training by those making the trimming decisions, and reengineering programs, caused the reduction of maintenance personnel. Part of the issue related to the reduction of personnel and maintenance programs is a simple rule of thumb: the full impact of a program is not felt for twelve to twenty-four months. This rule is known and holds true in business as well as within the maintenance organization.

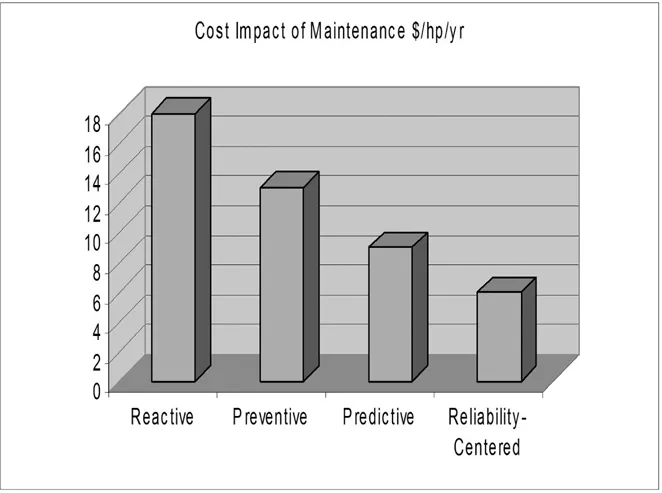

Figure 1: Cost of Maintenance Strategies

At the end of the 1980’s and into the 1990’s, senior management began to demand the same requirements for corporate projects of the R&M organization even while technology was finally at a point to improve the ability to ‘predict’ or estimate times to failure for machinery. The result was that maintenance personnel had to present business cases and justify work without the training to do so. The tools provided were ‘cost avoidance’ and ‘simple payback.’

In the 1960’s, the FAA worked with air carriers and manufacturers to develop the minimum maintenance requirements for aircraft. In the early 1970’s the US Military contracted two reliability managers from United Airlines, Nowlan and Heap, to develop Reliability-Centered Maintenance (RCM) for weapons and aircraft. The document, published in 1976 as ‘Reliability-Centered Maintenance,’ was a public document that drove future maintenance program development within all branches of the military, in particular the 3-M (Materials Maintenance and Management) for the US Navy. Developing and implementing maintenance for military and US Coast Guard equipment requires training in RCM and a continuous improvement program referred to as the Maintenance Effectiveness Review, or similar names. Military personnel are trained to generate and follow specific planning and scheduling as well as detailed step-by-step maintenance processes. Most industrial maintenance programs have at least one military experienced personnel.

In the mid to late 1970’s, newer testing technologies such as vibration analysis, hand-held electrical test equipment, ultrasonic equipment and more, began to enter the industry as non-destructive equipment. The use of the technologies accelerated towards the end of the 1980’s and began to become more common in the 1990’s. The benefit of such technologies has been the ability to detect different equipment defects without disassembly or interruption of production. However, these technologies require a great deal of training and experience for data interpretation. Additionally, the length of time between fault detection and equipment failure is generally difficult to predict by these personnel unless equipment failure history is readily available.

Maintenance knowledge tends to be handed down by word of mouth from an experienced technician to an ‘apprentice,’ or through trade or technical classes. Small changes to how maintenance is performed began to evolve over time such that inefficiencies and small changes developed based upon short cuts and work-arounds. For instance, proper lubrication of electric motor bearings has always required de-energizing the motor prior to adding a small amount of grease. With equipment not being shut down due to production requirements and a push to reduce overtime, bearings would be greased while the motors were running. Additionally, the position of ‘oiler’ or lubrication technician was replaced over time as it was assumed that lubrication did not require any significant skill. At some point in time, events occurred that propagated the change and added the concept of ‘flushing’ the bearings, or pumping grease until all of the old grease comes out of the bearing housing.

An example of how these changes occur happened in the 1990s in the Chicago area. In 1993 and 1994, a rash of bearing failures in belted applications occurred. We noticed this in the motor repair industry as the rate of failure was unusually high and tended to occur in commercial buildings. Finally, our team was brought in to review a catastrophic failure of a 75 horsepower motor in a commercial building. When we arrived, the wrench and six foot pipe used to tighten the adjustable base was still there and the belts had been tightened to the point where the shaft encroached into the bearing housing of the motor. When we traced it back further, it was discovered that a trainer teaching a class at a local High Voltage Air Conditioning (HVAC) school was teaching technicians to tighten belts by amp draw. The technicians were told to tighten the belts until the motor current met the nameplate value. To put this into perspective, most belted applications in commercial buildings are sized to about 50% of full load.

R&M professionals, be they maintenance technicians or reliability engineers, by and large have the goal of the company in mind: Keeping the assets up and running such that the company can produce product. They also must meet goals that are set for them, such as maintenance task completion and other R&M-related Key Performance Indicators (KPI). In many cases, in order to meet their goals as set forth with either paper or Computerized Maintenance and Management Systems (CMMS), the maintenance staff must take over production equipment. Predictive and Condition-Based Maintenance recommendations are submitted with recommendations based upon the tools that management has given them—cost avoidance numbers—and the results, recommendations or generic findings are ignored. The result is a level of frustration only countered by the increasing number of catastrophic unplanned failures that provide the rush that we discussed earlier.

Chapter 2

Maintenance and Management

“Ninety-nine percent of all problems in communications start with misunderstandings which develop as a result of differing viewpoints and conditioning.”

—Anonymous

The present issues associated with communication between maintenance and management are historical and not something that has just started, and can be seen in terms of centuries versus decades. The opinions and history of how things have developed differ based upon the point of view of the authors and intended audience. For instance, management books written by managers/academics and associated with MBA training tend to have very little information related to physical asset maintenance, while maintenance books tend to have very little information on executive management. In fact, in reviews of MBA textbooks, only a few discuss maintenance at all, and those tend to be limited to a few paragraphs. Several others ignored the function of skilled trades and labor and, instead, focus on how to hold a hard position with unions for negotiations. Most R&M training and books focus on how to present dollar savings and ‘value added’ information as the method of communicating with management.

In effect, both the R&M professionals and business professionals are being trained and educated into a communication gap problem! This shows, quite often, in the frustration levels of both maintenance and management concerning each other.

2.1 Guilds and Unions

The organization of labor practice is credited to Numa Pompilius, King of the Romans, who united musicians, carpenters and other artisans in 714-652 BC for the benefit of the community. This involved a trust that the people who requested work or services of the artisans would be guaranteed that they had the appropriate credentials.

For millennia prior to the industrial revolution, most people worked for themselves. As a result, they fashioned their own communities, which were later referred to as guilds in Europe, but had variations within all major countries from early times. Up through the middle ages, the guild increased in power, politically and economically, and provided insurance of quality and workmanship. With the expansion of the guild came the introduction of the middle class and the feudal system of Europe.

The guild structure ensured that craftsmen were selected and trained by a master craftsman over a long length of time. The guilds protected their crafts by being allowed to hold their own courts and punishment of their own membership while also providing shelter and a means of finding new work within the guildhalls. The guilds also provided a set of rules and requirements that protected quality, workmanship and the individual craftsmen, for instance artists were only allowed to paint during daylight hours and only in areas that were well lit. In these times, the master craftsmen and journeymen were the business owners contracted through the guildhalls to perform projects.

With the beginning of the First Industrial Revolution, the security of the worker, or craftsman, began to shift from individuals banding together to groups of workers working for a single company. This evolution occurred gradually, but significantly enough to change traditions that dated back millennia.

The First Industrial Revolution is estimated to have begun from 1750 to 1830 in Great Britain following rapid changes to the textile industry in 1740 relating to woolen garments. In 1793, the Industrial Revolution accelerated with the invention of the cotton gin by Eli Whitney in the USA.

The First Industrial Revolution blended in with the second revolution around 1850 when technology and economic progress gained momentum with the development of steam-powered ships and the railway. The improvement in transportation made mass production for a larger market a reality.

Thomas Savery constructed and patented the ‘Miners Friend’ steam powered low-lift water pump in 1698. This device utilized steam at 8 to 10 atmospheres producing about one horsepower of pumping power. It did not use pistons or cylinders and, therefore, was not considered a steam ‘engine.’ In 1712, Thomas Newcomen patented a piston and cylinder system that operated above atmospheric pressure and produced approximately five horsepower. This device was also used for pumping systems in mining applications.

James Watt patented the first real steam engine in 1776, which led to the development of the steam engine and steam ships. Steam power was also used as a method to produce local power and was instrumental in the development of more powerful machine tools such as the lathe, planning and shaping machines. This, again, allowed the building of bigger and more powerful engines impacting material transportation worldwide.

Later, towards the end of the nineteenth century, transportation and power improved even further with the development of the internal combustion engine and electrical power distribution. The DC, then later, AC electric motor, generator and distribution system accelerated production and manufacturing even more in the 20th Century.

Through all of these massive changes, labor and management had their struggles. In December of 1869, with changes to work and labor, an illegal, secret group started known as the Knights of Labor. This organized group worked towards the development of an eight-hour workday, the end of child labor and equal pay for equal work. The principles of the Knights were based upon Freemason concepts and rules. In 1886, the Knights of Labor lost their craft labor to the American Federation of Labor (AFL) and was non-existent by 1900.

The AFL was founded by Samuel Gompers in 1886 as a national federation of skilled workers’ unions. The Committee for Industrial Organizations (CIO) was created by John Lewis in 1933 and split for the AFL in 1938 to merge again in 1955 as the AFL-CIO. In the meantime, other unions, including the United Auto Workers (UAW), which was founded in 1935, mining unions, transportation unions and, later, company and government unions were developed.

The unions represented the same basic principles as the guilds of the past, including safety and power in numbers. The strength and power of these unions was tested, and established, with the 1936 UAW strikes in Flint, Michigan where workers locked themselves in while bargaining for a safer workplace, better wages, benefits and a slowdown of the push towards a much faster pace of assembly.

In general, since the 1800’s, the strength and power of unions have increased and decreased based upon general social feelings towards unions and business and government intervention.

2.2 Business Management and Manufacturing

In 1824, John Hall, Chief Engineer of Harpers Ferry Armory, developed a method of manufacturing muskets with inter-changeable components. In 1828, large-scale manufacturing of muskets using specialized machine tools and, primarily, lesser skilled machinists was implemented at the armory. This marked a specific divergence of the requirement for skilled and unskilled labor, reducing costs for the development of weapons coupled with the ability to provide replacement parts. The workforce was then split between the unskilled workforce (direct workforce) that operated machines and a skilled workforce (indirect workforce) who maintained, repaired, setup and built the machines used by the laborers.

Over time, this progress was brought into industry even though the implementation of the processes and special-purpose machinery philosophy had significant impact on volume without a sacrifice of quality. Between 1860 and 1885, for instance, McCormick of Chicago increased production of agricultural equipment from roughly 4,000 machines per year to almost 50,000. Singer, from 1856 to 1885 increased its annual production of sewing machines from roughly 2,500 per year to over half a million. Most of the time taken to make changes to the production systems was overcoming the craft culture within each company.

In 1878, Frederick Taylor began his work in developing a process that he established and published in 1911: Scientific Management. The concept behind this new philosophy was to achieve machine-like standards of speed and reliability at all levels within the company. The task of the scientific manager was to study the workers, determine the simplest and fastest way for their work to be done and set a standard time for performance. The concept was that the processes within each organization would be completely automatic and so simple that training would be at a minimum and very little decision making would be required.

In the first decade of the 20th Century, over 20 percent of the labor force was comprised of children aged 10 through 15. At the time, the life expectancy of men was 46.3 years and 48.3 years for women. Additionally, with a large influx of immigrants, unemployment remained about 15%, leaving the power of employment with the employers. If working conditions were dirty, dangerous or other...

Table of contents

- Cover

- Title

- Copyright

- Dedication

- Table of Contents

- Introduction

- Chapter 1: The Culture and Impact of Maintenance

- Chapter 2: Maintenance and Management

- Chapter 3: Skilled Workforce in the 21st Century

- Chapter 4: The Relationship of R&M to Corporate Productivity and Profitability

- Chapter 5: Overview of the Successful Development of Maintenance Management

- Chapter 6: Getting the Maintenance Process Under Control: Planning and Scheduling

- Chapter 7: A Few Maintenance Philosophies

- Chapter 8: Business Impact of Maintenance Programs (Summary)