Driving the Enterprise to Sustainable Excellence

A Shingo Process Overview

- 192 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

This book presents a big-picture overview of the entire Shingo improvement process. It fully discusses the needs and benefits of the Shingo process, and what is required if you seek to execute the Shingo Model in your enterprise and focuses on creating an enduring organization-wide continuous improvement process. It gives the reader a discussion of the entire Shingo experience while most existing books on the model are course-specific.

There are numerous discussions, conference talks, and webinars of why the Shingo process is beneficial, and what types of improvements can be achieved, but the crucial material has not been assembled in one concise book, giving the executive, manager, or supervisor an overview and understanding of what the Shingo experience entails. The main purpose of this book. It is for the executives who want to understand their role in supporting and leading middle management with its implementation. Many executives from developing countries all over the world are seeking a concise definition of what the Shingo model is, and this book functions as the perfect primer. Even those who have attended and implemented the lessons from the Shingo Institute's courses would find this book a benefit as it serves perfectly as backup and reference material. In addition, this book helps anyone who has started their journey with the Shingo model and may be confused about what to do and expect -- It gives them a vision of what the continuing journey will look like. The Shingo process is being taught at numerous universities and this book could indeed serve as the appropriate textbook or supplemental reading.

Essentially, this book teaches an innovative and extremely successful approach to continuous improvement, referred to as the Shingo process. It is based on a set of universally accepted principles that are endorsed by improvement leaders such as Covey and companies such as Toyota. This book is not a detailed review or a replacement of the Shingo workshops. It is an overview of the entire Shingo process, starting with a discussion of the challenges that many of todays enterprises are experiencing.

The author, in his role as a PhD in economics, has studied industries and has worked closely with many of them attempting to understand their weaknesses. This book builds upon an understanding of these weaknesses. The book discusses how the over-all Shingo methodology fits into these organizations and highlights the benefits. The next step is then to discuss what requirements are necessary for an organization to get ready for a Shingo transformation. What are the steps that the organization needs to go through, and when will it know that it is ready to begin? The book briefly reviews the Shingo Insights and Principles and explains how the Shingo courses should be best utilized to facilitate the desired transformation. It suggests some alternative plans for over-all implementation based on the current state of the enterprise. It explains why there is no "one way" for successful implementation and how the implementation sequence needs to be customized. It also discusses the length of time needed for success and how this differs depending on the current enterprise environment.

Lastly the book explains how the implementation and Shingo training is never finished. It is an on-going process and success is defined by internal improvements, not by some arbitrary external benchmark. The book is intended to be educational, thought provoking, entertaining in its stories and examples, and a guideline towards the development of a plan for continuous improvement. This book is filled with stories and examples, showing successful and not so successful implementations. The stories are used to highlight many of the pitfalls that have arisen and may arise for you and which can be avoided if the reader is aware of them and knows how to watch for them.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Part I

The Growth of the Shingo Approach

1

A Personal Experience

When I began visiting companies and production plants, there was one thing I almost always used to tell company presidents, “The medicine I am prescribing for you is a miracle drug and very powerful, but there is one problem with it.”“What problem?” they would say.“The problem,” I would explain, “is that the medicine won’t work unless you take it. I may tell you wonderful things, but you’re not going to be successful unless you actually do what I’m telling you.”Shigeo Shingo

The Story of a Drive to Enterprise Excellence

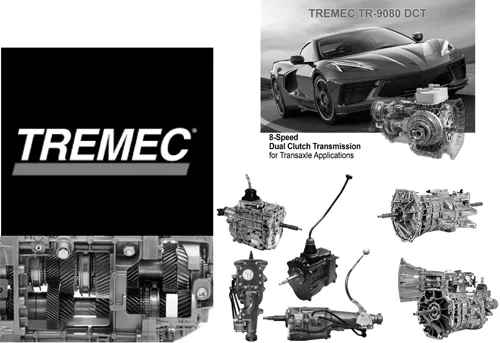

TREMEC.

Most of the workers are unskilled: they have difficulty filling out time sheets. Most production was kept on schedule by chasing particular jobs around the plant in an attempt to get them done quickly. Although TREMEC has education programs with full-time instructors and classrooms, the need for more complete education for factory workers far exceeds the capacity of these education facilities.

An adversarial relationship exists between top management and the heavily unionized labor force. The average unskilled worker resents his rich Mexican boss, who looks down on him. These workers also resent the Americans, who have to communicate with them through an interpreter, and who also make them feel inadequate.

The average worker has a set of (personal) goals that are quite different than those of the company. He doesn’t consider himself a part of the company, and he wants to spend as much time as possible with his family. This often means that after receiving a paycheck, he may not show up for work for several days. He’ll return when he feels a financial necessity to go to work again.

… production was scheduled using a computerized production control systems whose schedules were changed by the expeditors trying to push rush jobs through the plant. These altered schedules were then adjusted by the North American advisors … those schedules were overridden by top management.

Middle management positions … are often filled through nepotism.

Strikes occur frequently.

Deliveries of raw materials are sporadic. … Therefore raw materials are heavily stockpiled.

Equipment repair relies on scavenging for spare parts. … As a result, some of the machinery in the facility is usable only as a source for spare parts. … An enormous amount of scrap has accumulated due to obsolescence or to operational error. Gears that are several years old and red with rust are piled high in the yards.

Production schedules are generated using unreliable standards. Much of the problem with the standards centers around the poor processes used to collect data. The employees recording production data do not understand its purpose and do not understand the procedures for recording information.

- 1. Unskilled work force – A recommendation for simplified input documents and input tools that do not require written information.

- 2. Unskilled middle management – Training on manufacturing production and control topics, including what metrics are critical.

- 3. Poor employee-management relations – Open sharing of information between all levels and helping them understand what the information is telling them.

- 4. Machinery that is too old, causing numerous breakdowns, or too technologically new and is therefore poorly understood – The recommendation here centers on a discussion about capacity management and safety machine capacity.

- 5. Poor power supplies – Power protection equipment and backup power systems.

- 6. Difficulty in (electronic) communications – This solution recommends a separate computer/technology center so that when a strike occurs, the entire facility is not shut down.

- 7. Poor or meaningless production standards – Improved data collection and manufacturing controls and efficiencies are recommended.

- 8. A crisis management mentality – Improving data and information will reduce tension.

- 9. High inventories – High inventories in raw materials, work in process, and finished goods need to be reduced and scrapped using tools like Lean’s 5S program.

- 10. Poor routings – Improved data collection is critical.

- 11. Errors in data collection – Simplify the data collection process minimizing the need for writing and increasing the use of automated data collection where button pushing is all that is needed.

- 1. “Any system that is not designed by a user will be only half effective.” Systems should not be designed and implemented without the user’s input.

- 2. “Save the manual system. If nothing else, the manual system can serve as a back-up system if the computer system fails.” The two systems should mirror each other. There will be failures and shutdowns, but there should be logical workarounds.

- 3. “Never computerize something that doesn’t work manually on a smaller and simpler scale. … The idea that changing a system instills discipline is false. Discipline is instilled by motivated management direction.” The computer system should never complicate life. If it doesn’t make things simpler for the user, the user will defeat it. Any time a system, computer or otherwise, doesn’t make life easier for the user, it fails. Remember the saying that, No matter how good a system is, if it isn’t easier to use than the previous system, and if the user isn’t involved and own the system, it will fail. Similarly, no matter how poor a system is, if it’s easier to use, and if the users have ownership in it, it will succeed!

- 4. “Choose a software system first, never the hardware.”

- 5. “When considering the three phases of a system: input, process, and output, always analyze the output first and define the user’s needs. Then analyze the required input to make sure the system’s output requirements can be met.”

- 6. “The systems analyst is generally wrong in any disagreement with the users. The users have to live with the system, so give them what they want.”

Table of contents

- Cover

- Half-Title

- Title

- Copyright

- Dedication

- Contents

- Acknowledgments

- About the Author

- Introduction

- PART I The Growth of the Shingo Approach

- PART II The Shingo Methodology

- PART III Bringing It Home

- Index