- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Digging mineral wealth from the ground dates to prehistoric times, and Europeans pursued mining in the Americas from the earliest colonial days. Prior to the Civil War, little mining was deep enough to require maps. However, the major finds of the mid-nineteenth century, such as the Comstock Lode, were vastly larger than any before in America. In Seeing Underground, Nystrom argues that, as industrial mining came of age in the United States, the development of maps and models gave power to a new visual culture and allowed mining engineers to advance their profession, gaining authority over mining operations from the miners themselves.

Starting in the late nineteenth century, mining engineers developed a new set of practices, artifacts, and discourses to visualize complex, pitch-dark three-dimensional spaces. These maps and models became necessary tools in creating and controlling those spaces. They made mining more understandable, predictable, and profitable. Nystrom shows that this new visual culture was crucial to specific developments in American mining, such as implementing new safety regulations after the Avondale, Pennsylvania fire of 1869 killed 110 men and boys; understanding complex geology, as in the rich ores of Butte, Montana; and settling high-stakes litigation, such as the Tonopah, Nevada, Jim Butler v. West End lawsuit, which reached the US Supreme Court.

Nystrom demonstrates that these neglected artifacts of the nineteenth and early twentieth centuries have much to teach us today. The development of a visual culture helped create a new professional class of mining engineers and changed how mining was done. Seeing Undergound is the winner of the 2015 Mining History Association's Clark Spence Award for the best book on mining history.

Starting in the late nineteenth century, mining engineers developed a new set of practices, artifacts, and discourses to visualize complex, pitch-dark three-dimensional spaces. These maps and models became necessary tools in creating and controlling those spaces. They made mining more understandable, predictable, and profitable. Nystrom shows that this new visual culture was crucial to specific developments in American mining, such as implementing new safety regulations after the Avondale, Pennsylvania fire of 1869 killed 110 men and boys; understanding complex geology, as in the rich ores of Butte, Montana; and settling high-stakes litigation, such as the Tonopah, Nevada, Jim Butler v. West End lawsuit, which reached the US Supreme Court.

Nystrom demonstrates that these neglected artifacts of the nineteenth and early twentieth centuries have much to teach us today. The development of a visual culture helped create a new professional class of mining engineers and changed how mining was done. Seeing Undergound is the winner of the 2015 Mining History Association's Clark Spence Award for the best book on mining history.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Seeing Underground by Eric C. Nystrom in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & North American History. We have over one million books available in our catalogue for you to explore.

Information

Publisher

University of Nevada PressYear

2014Print ISBN

9780874170078, 9780874179323eBook ISBN

9780874179330PART I

Mine Maps

Chapter 1

Underground Mine Maps

Maps are powerful because they allow us to learn or know about places that might be far from our present experience, but in a way that relates the unknown to other places on the earth. They organize and represent space visually. However, most people don't need a map of their hometown in order to find their way around. Through long exposure, we usually build a map in our heads that allows us to navigate more efficiently; physical maps are, in that sense, not a prerequisite to finding our way.

The same was true with underground mines in the preindustrial era—maps were rare and largely useless, of little importance to mining operations. The veins led the miners, and the works evolved slowly enough, in the era before high explosives and mechanical drilling, that keeping track of underground progress was not difficult. Mines of that era rarely had problems that underground maps could help solve. However, as mining became industrialized in the late nineteenth and early twentieth centuries, maps moved from nonexistent, to an afterthought, to an important way of portraying the mine, to a key managerial tool. Underground maps were the most central element of the visual culture of mining, created and wielded by mining engineers in the era of industrial mining in the late nineteenth and early twentieth centuries. This shift is rooted in the visual properties of maps. Maps are powerful things.1 Mine maps were not like those that historians of cartography have ordinarily studied, however. Because they were unpublished, made by the application of mechanical drawing techniques, and created by engineers for engineers, underground maps share some of the same properties as engineering drawings—the “technological representations” that help engineers wield power and control, as explained in the introduction.

This chapter will provide a broad overview of underground maps, looking in detail at how they were made and used, and showing some of the changing forms of mine maps over time. The chapter will also explore how mapping became an important element in the education of mining engineers, and how it grew to be a central part of the professional identity of mining engineers as they competed with other groups for jurisdiction over underground work.

The first step in creating or revising an underground mine map was to perform a survey. Surveying was the process of using instruments to measure angles and distances; engineers could later use this information to measure and plot a map of the mine at a reduced scale on paper, using geometrical principles.

Maps of surface landscapes have been associated with mining for many centuries, including some of the earliest maps associated with mining in the United States. Such maps, made with the same tools and techniques as other surface maps, show the surface location of mineral deposits or land ownership claims. Many Western states required a surface map of a claim to be made by a certified US deputy mineral surveyor before the claimants could transfer it to private ownership by patenting the claim. While such surface maps were important, they did not require specialized personnel to create or use them. If an ordinary land surveyor could make a map that included a house or a stand of timber, the same surveyor could note a mining property line or mineral outcrop. Certification of deputy mineral surveyors was important not necessarily because they possessed extraordinary skills, but to help reduce conflict over claims surveyed by competing companies. As a result of the relative simplicity of these surface maps, particularly in the early years, they contributed little to the development of the visual culture of mining.

In addition to surface property and claim maps that depicted the surface of the earth, another precursor of underground maps were geological maps that purported to show geology below the surface. The geological sciences coalesced rapidly in the first several decades of the nineteenth century, and the visual representation of geological features played an important role in geological interpretations.2 William Smith is usually credited with having produced the first geological map, in 1815.3 Even so, J. P. Lesley, a well-known American geologist, lamented in 1856 that geological maps “are commonly mere distortions and caricatures which illustrate the subject by confusing the observer. Neither maps nor sections are helps to the geologist—and are cruelties to the schoolboy—unless they be properly and accurately made. Then they become his efficient tools. But he must make his own tools. He will find none made to his hand. The age of maps has just set in.”4

Lesley's 1856 Manual of Coal and Its Topography did not discuss underground mapping at all. One significant reason is that there was little mining activity in America in 1856 that was deep enough to map, and few engineers who might have done the work. This situation changed dramatically in the decades to follow, and it started with surveying underground mines.

Underground surveying shared much in common with surface topographical surveying. Both measured areas by noting distance and angle measurements between a series of points designated by the surveyor, as well as known topographical features such as large trees, church steeples, roads, or surveying monuments. Surveyors then plotted these points and measurements on a map.

However, mine surveying introduced several complications into normal surveying practice. On the surface, a surveyor could orient work to true north by observing the sun, the stars, or a natural reference point in a known location such as a mountaintop or church steeple. Underground, none of these options was feasible, which meant that a known reference and orientation had to be carried underground from a surface survey. Underground mines were dark, which meant that instruments and targets had to be illuminated with lamps. The cramped spaces underground often required a dexterous transit operator, and in some cases required alternatives to ordinary tripods to save space. Mines were also hazardous, with uneven floors, dirt, damp, and rocks, all of which made the surveyor's job less pleasant and prone to additional inaccuracy. Finally, the linear nature of underground mines made errors more likely. In surface surveying, an important principle is to create a closed polygon, surveying around the land until the survey ends where it begins. This method gives the survey operator an effective check against mistakes in measuring angles, since the angles of a polygon must add up to a particular value that is dependent on the number of angles, not their degree measurements. If the measured angles are not close to the predicted total, a measurement was off and the survey should be double-checked.5 However, the shapes of underground spaces made it difficult for surveyors to measure them with a closed polygon, often denying underground surveyors an additional check on the accuracy of their work.

Executing underground surveys required a collection of tools, each with a particular application in the series of steps involved in a survey. These tools, in turn, each had a history of its own; they were gradually refined by their makers with an eye toward cost, accuracy, and speed. Thousands of engineering hands, spread across the country, formed the visual culture of mining with these tools, just as a carpenter's hammer produces a house. Let us examine each of them briefly.

In order to determine side-to-side and up-and-down angles, preindustrial miners generally used two tools. One was the compass, which could measure side-to-side angles in the same fashion underground as above ground. The other was a clinometer, used for measuring up-and-down angles, where a weighted tongue or plumb bob would point toward the ground and the edge of the protractor-like clinometer would represent the angle to be measured. Miners usually used these tools by tightly stringing a stout cord between the points to be measured. They then could place the compass and clinometer along the cord and take the measurements. Later evolutions of compass and clinometer were given gimbals and little arms to hang on the stretched cord, resulting in the hanging compass. As may be imagined, these tools were cumbersome to set up and use, and were not very accurate by later standards; given the limited role of visual information in preindustrial mining, though, the deficiencies may not have been an issue.6

The compass, in particular, had inescapable defects and unique advantages. As was recognized above ground, the variation of magnetic north from true north on a regular and unpredictable basis meant that readings in the same spots on different days might yield different results. Advocates of the compass pointed out that, for surveys that could be completed in a single day, the compass was accurate enough, as all readings on a particular day would have the same declination from true north, making them at least accurate with respect to each other. As may be imagined, as industrial mining created mines of multiplying underground complexity, this defect of compasses became more problematic. The other issue with compasses was that they were deflected by the presence of iron nearby. This meant they could not be used in iron mines, for example, and over time, as iron machinery became more common in industrializing mines, the presence of pipes, tracks, and other items rendered them so unreliable they became nearly useless for accurate work.

Even so, the compass had several advantages that kept it in use in more conservative mining regions, such as Cornwall, for many decades after optical surveying instruments had become standard. One advantage was that the compass was fairly simple to understand, and required no more expertise to use below ground than above. A second, important feature was that a compass could provide a bearing below ground to start a survey that was consistent with one taken on the surface (presuming the needle was not deflected by the presence of underground machinery). This allowed the engineer to orient the geometric polygon he created with proper respect to surface features. This feature kept compasses as part of the equipment of many mining transits well into the era of industrial mining, though compass readings eventually served primarily as an additional check against clerical errors.

A major change in surveying equipment occurred in the early nineteenth century, with the development of optical, rather than magnetic equipment. These new instruments were more accurate than magnetic compasses, but were also considered more delicate, slow to use, and—importantly—expensive. Such optical instruments were commonly called theodolites, though many individual inventors had pet names for their own creations; as we shall see in a moment, most mine surveying in the industrial era was conducted with an improved successor to the theodolite, the transit.7

Theodolites and transits measured angles on both vertical and horizontal axes. In principle, a horizontal tube or telescope was mounted with extreme precision at its horizontal and vertical pivot, meaning that as the tube was moved from side to side and up and down to bring the target into view, it accurately measured the horizontal and vertical angles on scales attached directly to the instrument. Since there was no reliance on the attraction of a magnetized needle to the earth's magnetic field, such an instrument worked perfectly even where iron was abundant. Furthermore, as instrument manufacturing became more precise, optical instruments, in turn, could provide readings that were more precise, where reliance on the variation of a compass needle would inevitably leave a larger margin of error even in compasses with the finest craftsmanship.

While the theodolite was used widely in railroad and land surveying, and in some mines, especially abroad, the visual culture of American industrial mining rested primarily on surveys made with the transit. Theodolites of that time used a quarter or half circle, measured in degrees, to record vertical angles; the transit by contrast used a full circle, graduated all the way around, and mounted a shorter telescope higher above the base of the instrument. As a result, unlike the theodolite, the transit's telescope could flip completely over in its mountings. This allowed mining engineers to turn their transits over to obtain a set of check readings, ensuring both that the instrument had not been knocked out of alignment and that no mistakes had been made in obtaining or recording the readings.

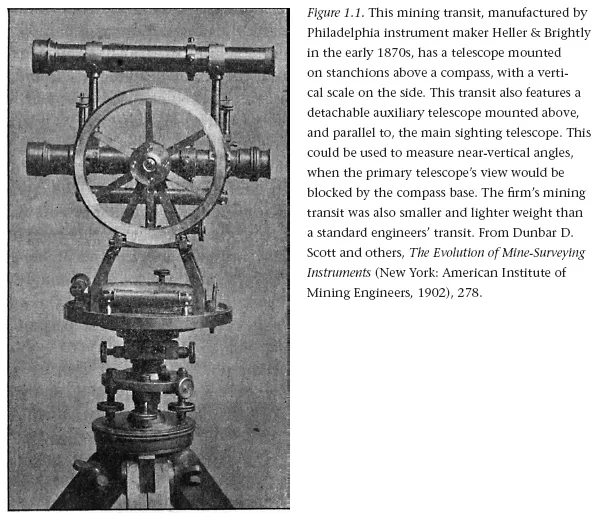

Several variations on transits were used by mining engineers to solve surveying problems peculiar to mine surveying. Many transits through the end of the nineteenth century were made with large integrated compasses, which could be used to orient the instrument or as a further source of data that could provide a double check of the optical readings. One issue was that mining engineers were much more likely to have to measure steep vertical angles, in measuring shafts or raises, for example, than would a surveyor using a theodolite on the surface. If the transit telescope was mounted directly over the center of the instrument, its base interfered with measuring angles beyond about seventy degrees. Mining engineers and instrument makers developed several designs to cope with this problem, including mounting an additional removable telescope, called an auxiliary, on top of or to the side of the main tube, where it would provide a clear view at a vertical angle. A different solution could be had by setting the transit's telescope off from the vertical center of the instrument on inclined stanchions. An auxiliary telescope can be seen in the Heller & Brightly mining transit, made in the mid-1870s, in figure 1.1.

Whatever instruments they chose, mining engineers used surveying to connect points within the mine, and made maps based on these skeletal measurements. Any type of surveying is dependent on establishing carefully located points of reference on the earth, usually called surveyor's stations. Common examples for ordinary land surveying include nails or stakes driven into the ground; readers may be familiar with the brass plaques, set in concrete, that serve to anchor nationwide geodetic surveys. Underground surveying required a modification of this practice. Mine surveyor's stations could not be established with precision on the floor of the mine because work traffic would disturb them. Consequently, the stations in a mine normally consisted of a horseshoe nail with a hole or a hook (known as a spad or spud) driven into a mine timber or a wooden plug inserted in a small hole in the roof. Over time, it became common as well to permanently mark a station's number in the mine's survey system by attaching a metal tag to the spad or painting the number on the adjacent wall.8

Over time, these survey stations became part of a permanent information infrastructure in the mine. Early mine surveyors did not always associate a permanent number with a particular survey station, but over time it became common for them to give each an identifier of some kind. One system was to designate each surveyor's station with a unique number, so no two stations would be the same. This system could be used by inspectors and others not intimately familiar with the mine to help orient themselves. Its drawback, however, was that numbers might not be consecutive as work progressed in a particular area, and one surveying crew had to keep a master list of numbers.9 By contrast, a competing system numbered stations consecutively from the beginning point of the survey, but added a notation to each that reflected the cumulative distance from the beginning point. This system made it easy to calculate distances between stations on the map or, if the stations were visibly labeled, underground. Though the station numbers seemed confusingly similar to each other at first glance, practice suggested the system was not difficult to understand, reported one engineer who surveyed this way, but in the end he concluded, “[B]oth of these systems are used extensively, however, and mine transitmen do not often wish to change from their first love.”10

The survey stations were aligned with the mining engineer's equipment using small plumb bobs—pointed weights at the end of a string. In surface surveying, the surveyor placed a theodolite over the surveyor's station, then hung a plumb bob from the underside of the instrument on an eyelet at the very center of the device (at the top of the underside of the tripod). The surveyor then moved the theodolite and tripod until the bob pointed precisely at the center of the surveyor's station on the ground. Once the perfect position was achieved, the instrument was made level using leveling screws. In a mine, where the surveyor's stations were located overhead, mining engineer...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Contents

- List of Illustrations

- Preface

- Introduction

- Part I - Mine Maps

- Part II - Mine Models

- Conclusion

- Notes

- Bibliography

- Index