- 448 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Handbook of Weaving

About this book

A mixture of science and art, weaving is nearly as old as human history. Despite the many technological advances in the field, however, it is still virtually impossible to control each individual fiber in a woven structure. To help you meet this and other weaving challenges, Handbook of Weaving covers every step of the process clearly and systemati

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Handbook of Weaving by Sabit Adanur in PDF and/or ePUB format, as well as other popular books in Business & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

1

Fabric Formation by Weaving

1.1 FABRIC FORMATION METHODS

In general terms, a textile fabric may be defined as an assembly of fibers, yarns or combinations of these. There are several ways to manufacture a fabric. Each manufacturing method is capable of producing a wide variety of fabric structures that depend on the raw materials used, equipment and machinery employed and the set up of control elements within the processes involved. Fabric selection for a given application depends on the performance requirements imposed by the end use and/or the desired aesthetic characteristics of the end user, with consideration for cost and price. Fabrics are used for many applications such as apparel, home furnishings, and industrial.

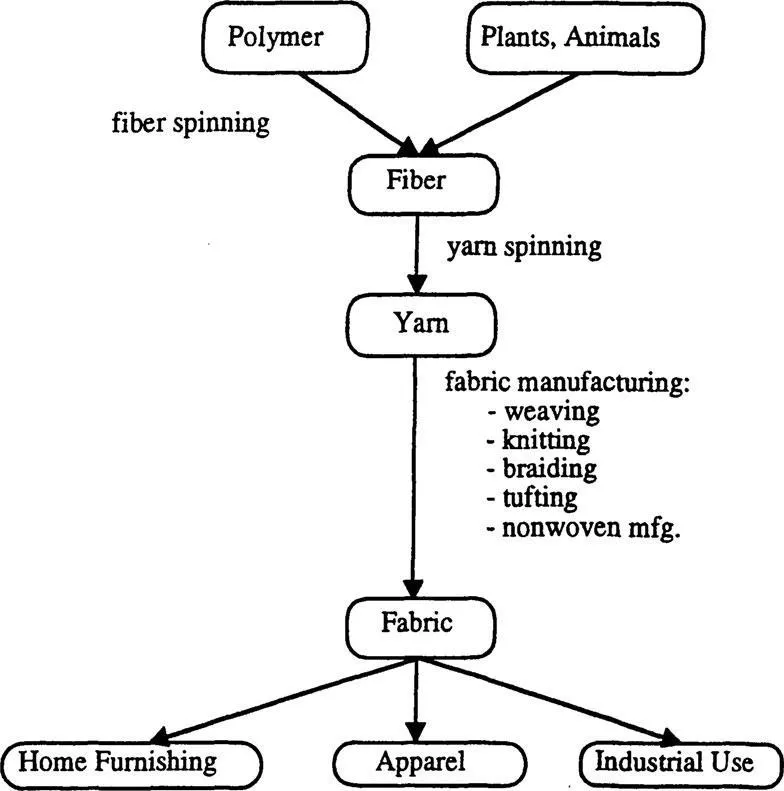

Figure 1.1 shows the major steps in fabric manufacturing. Polymers are the resource for man-made fibers. Polymers are derived mostly from oil. Plant fibers and animal fibers constitute the natural fibers. After the fabric is formed, it is generally subjected to a finishing and/or dyeing process, in which the raw fabric properties are modified for the end use.

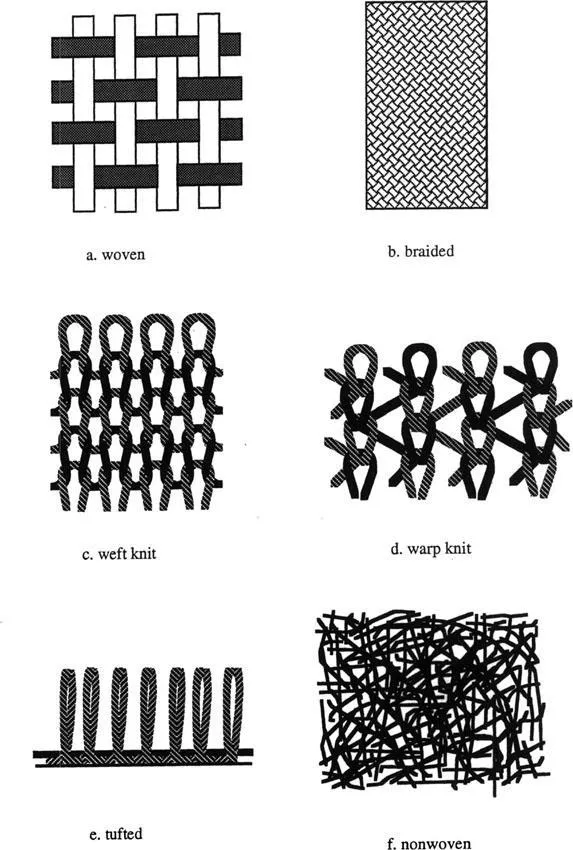

The most commonly used fabric forming methods are weaving, braiding, knitting, tufting, and nonwoven manufacturing. Figure 1.2 shows the schematics of fabrics produced by these methods.

Weaving is the interlacing of warp and filling yarns perpendicular to each other. There are practically an endless number of ways of interlacing warp and filling yarns. Each different way results in a different fabric structure.

Braiding is probably the simplest way of fabric formation. A braided fabric is formed by diagonal interlacing of yarns. Although there are two sets of yarns involved in the process, these are not called warps and fillings as in the case of woven fabrics. Each set of yarns moves in an opposite direction. Braiding does not require shedding, filling insertion, and beat up. The yarns do not have to go through harnesses and reed. Braiding is generally classified as two dimensional and three dimensional braiding. Two dimensional braiding includes circular and flat braids. The application of two dimensional braiding is very limited in apparel manufacturing. Three dimensional braiding is a relatively new topic, and mainly developed for industrial composite materials.

Knitting is interlooping of one yarn system into vertical columns and horizontal rows of loops called wales and courses, respectively. There are two main types of knitting: weft knitting and warp knitting. In weft knitting, the yarns flow along the horizontal direction in the structure (filling or course direction); in warp knitting, they flow along the vertical direction (warp or wale direction). Special needles are used to form the yarn loops. The basis of knit fabric structure is the continuing intersection of loops. This feature provides unique characteristics to the knit fabrics compared to woven and braided fabrics. Practically, there are an endless number of knit fabric structures. Knit fabrics are widely used in apparel and home furnishings. They are also used in technical textiles, such as artificial arteries, bandages, casts, composites, sporting equipment, etc.

Tufting is the process of manufacturing some carpets and similar structures. A surface yarn system of loops is “sewn” or “stitched” through a primary backing fabric, usually a woven or nonwoven fabric. The loops are arranged in vertical columns (rows) and horizontal lines (stitches). Loops can be in the form of cut or uncut loops (piles) or a combination of thereof. The fabric is usually back-coated in a later process to secure tufted loops.

Bonding is the method of manufacturing nonwovens using either textile, paper, extrusion, or some combination of these technologies, to form and bond polymers, fibers, filaments, yarns or combination sheets into a flexible, porous structure. The resulting structure is quite different than the structures mentioned above. In fact, some nonwoven products are claimed by both the textile industry and paper industry.

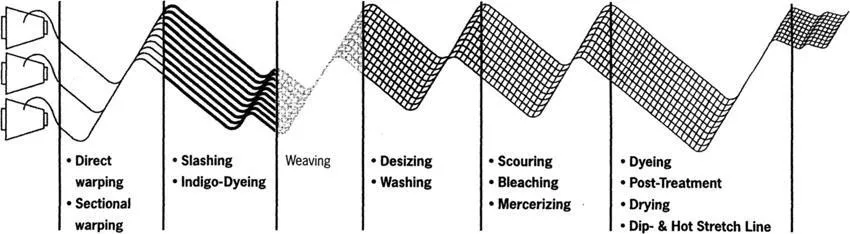

Each of these major fabric manufacturing processes produces unique structures. Big industries have evolved around each method of fabric manufacturing in almost every country in the world. Around 40 countries have major textile industries and another 50 countries produce woven fabrics in various amounts. Approximately 70% of the fabrics made in the world are woven fabrics. Figure 1.3 shows the major steps in manufacturing of finished woven fabrics. This book is concerned only with the weaving process and woven fabrics.

Weaving of yarns into a fabric is performed on a “weaving machine” which has also been called a “loom”. However, “loom” is more descriptive of a “shuttle weaving machine”. For shuttleless “looms”, the term “weaving machine” is more appropriate since these machines are as sophisticated as any other machine that exists today. A typical modem weaving machine consists of up to 5000 parts working together in a very precise manner. Although shuttle looms have been obsolete, reference is still made to them, for comparison purposes, when describing shuttleless weaving machines.

1.2 WEAVING AND WOVEN FABRICS

1.2.1 History of Weaving

Weaving is probably as old as human civilization. One of the basic necessities of humans is to cover their bodies to protect themselves from outside effects (hot, cold) and look more “civilized” to the eye. Other reasons for development of different clothing throughout the history are social status, religious requirements, etc. Clothing trends depend on location as well.

Historical findings suggest that Egyptians made woven fabrics some 6000 years ago. Chinese made fine fabrics from silk over 4000 years ago. It is believed that the hand loom has been invented many times in different civilizations [2].

Weaving started as a domestic art and stayed as a cottage industry until the invention of the fly shuttle. The fly shuttle, invented in 1733 by Kay, was hand operated. In 1745, de Vaucanson made a loom, further developed by Jacquard, to control each warp end separately. In 1785, Cartwright invented the power loom which could be operated from a single point. In the early 1800s, looms made of cast iron, were operated by steam power. Power loom required stronger warp yarn, resulting in development of the first sizing machine in 1803. In the 1830s, there were some 100,000 shuttle looms operating in England. The processing principles of these looms were pretty much the same as today’s shuttle looms.

Table of contents

- Cover

- Title Page

- Copyright Page

- Table of Contents

- Introduction

- 1 Fabric Formation by Weaving

- 2 Overview of Polymers, Fibers and Yarns used in Woven Fabrics

- 3 Woven Fabric Design and Construction

- 4 Weaving Preparation

- 5 Weaving Fundamentals

- 6 Shedding Systems

- 7 Shuttle Weaving

- 8 Jet Weaving

- 9 Projectile Weaving

- 10 Rapier Weaving

- 11 Multiphase Weaving

- 12 Manufacturing of Special Fabrics

- 13 Fabric Structure, Properties and Testing

- 14 Weaving Plant Operations

- 15 Future of Weaving

- Appendix 1: Characteristics of Major Weaving Machines Produced in the World

- Appendix 2: Troubleshooting In Warping and Sizing

- Appendix 3: Typical Sizing Examples of Common Fabric Styles

- Appendix 4: Examples of Temples Used in the Textile Industry

- Appendix 5: Units and Conversion Factors

- Index