eBook - ePub

Great Book of Woodworking Projects

50 Projects For Indoor Improvements And Outdoor Living from the Experts at American Woodworker

Randy Johnson

This is a test

Share book

- 250 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Great Book of Woodworking Projects

50 Projects For Indoor Improvements And Outdoor Living from the Experts at American Woodworker

Randy Johnson

Book details

Book preview

Table of contents

Citations

About This Book

From kitchen improvements and furniture, to gifts and small projects that can be done quickly, the experts at American Woodworker provide plans and instructions for building 50 great looking projects for every room in the home. With a variety of style and skill levels included, there is something for every woodworker in this book. Step by step guidance, workshop tips, and plans for projects that can take a few hours to a weekend to complete, make this an ideal resource for woodworkers looking for a new project or wanting to spruce up their home.

Frequently asked questions

How do I cancel my subscription?

Can/how do I download books?

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

What is the difference between the pricing plans?

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

What is Perlego?

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Do you support text-to-speech?

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Is Great Book of Woodworking Projects an online PDF/ePUB?

Yes, you can access Great Book of Woodworking Projects by Randy Johnson in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Technical & Manufacturing Trades. We have over one million books available in our catalogue for you to explore.

Information

Furniture Projects

If you want to build your skills or are looking to build a fine piece of furniture for your home, then this is the section for you. It includes ten great projects ranging from a natural slabwood bench to a Stickley sideboard reproduction with handmade copper hardware. If you’re new to woodworking and looking for a project that covers some of the basics, check out the speaker stand. It doesn’t take much wood or many tools to build, yet it incorporates several joints and techniques that you can later apply to larger projects. For something more involved, try the stowaway bench or kitchen work table. If you’re really looking for a substantial project using traditional joinery and design, consider the Stickley-style chest of drawers. Made of quartersawn oak with mortise and tenon joinery, it might become a family heirloom that the kids wrestle for. If you’re truly the engineering type with a penchant for math, angles, and precision, the Arts and Crafts table lamp should be enough to get you into your shop with calculator and miter gauge in hand. Designed with lines that are reminiscent of Frank Lloyd Wright, the lamp provides a more technical challenge than some larger furniture projects.

by GREG WOOD

Natural Bench

HOW TO MAKE STRONG JOINTS IN SLABWOOD

When I need wood for a project, my first stop is a small mill near my shop that specializes in local hardwoods. On one particular visit I noticed a pile of offcuts sitting out in the rain. As I pawed through the pile, a slab of white oak caught my eye. The sawn surface was wet and the grain just popped. The bark was almost completely gone on the flip side, leaving a smooth, natural surface that was miraculously free of damage from chainsaws and harvesting equipment. Turns out the slabs were free for the taking so I took several slabs back to my shop to dry.

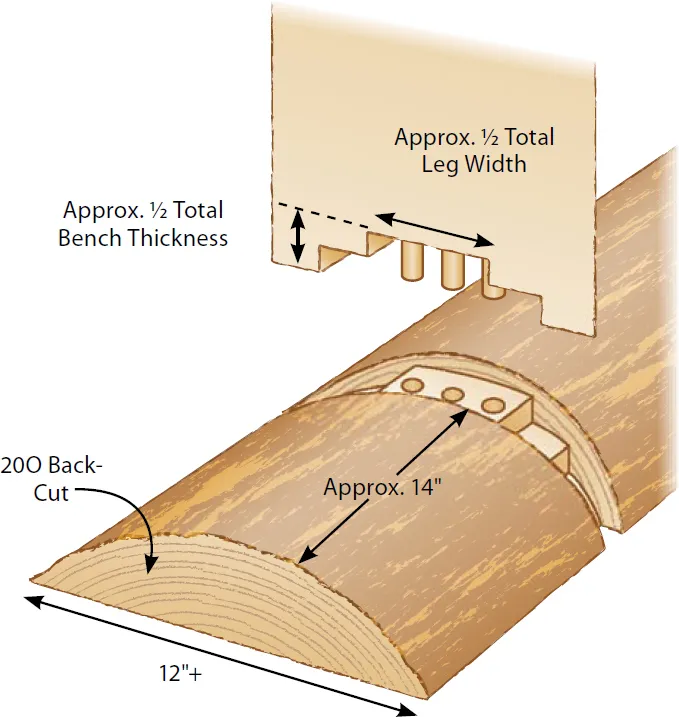

For months I kept wondering what to make with the slabs. The undulating line where the flatsawn surface met the natural edge of the log intrigued me. From some angles, the plank’s thickness was almost invisible. Eventually, I decided a bench would be the best way to retain the natural look of the slab and highlight its best features. The slab’s 14-in. width was wide enough to provide sufficient stability, and at over 1 1/2-in. thick, it was plenty strong. That inherent strength and a unique joint I came up with allowed me to eliminate the typical stretcher between the legs and help keep the design as clean and natural looking as possible.

I still had to figure out how to orient the legs to the slab. I turned the natural sides of the legs inward to keep all of the natural surfaces facing one another.

Leg position was another big decision. I once had a bad experience with a cantilevered bench like this. There were three of us on a bench, two got up and guess who ended up on the floor? The lesson was that there are limits to how far you can safely cantilever a bench seat. I adjusted the legs on a prototype bench and made some test sittings until I found a point where the legs were offset enough to look visually pleasing without making the bench tippy or unstable.

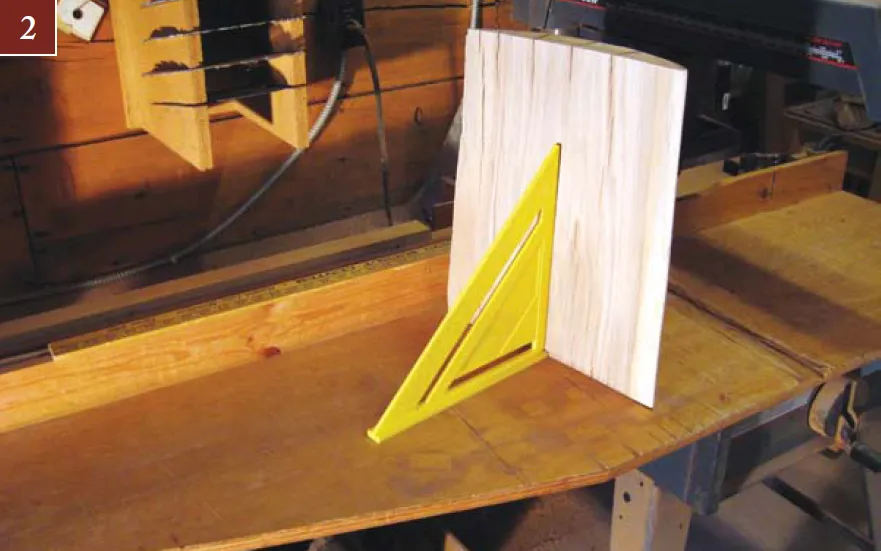

The first step is to create a smooth, flat surface on the roughsawn face of the log. I used a hand plane and power sanders.

Toe-kick drawer and pull-out trash drawer add convenience to the kitchen.

A flap sander quickly removes oxidation and loose debris from the slab’s bark side. Don’t try for a perfect surface. Just sand smooth to about 180-grit.

Build a bridge over the seat to rout the mortises. The bridge acts as a straightedge to guide the cut and a platform to support the router.

Use a template to lay out the mortise for each leg on the seat plank. Make the template by tracing the top of the leg onto a piece of paper.

Rout the center portion of the mortise with a top- bearing flush-trim bit. The stepped ends of the mortise will be finished later. Use the edge of the bridge to guide the bit along the mortise’s straightedge. Move the bridge slightly to rout the rest of the mortise.

Figure A: Joinery

Prep the Slab

The first step is to flatten and smooth the sawn face of the slab (Photo 1). You can use a hand plane to remove milling marks and any twist or warp. If there’s a lot of material to remove, a handheld power plane is easier. Sand to 180-grit, using a random orbit sander. This provides a f...