eBook - ePub

Mechanism Design

Visual and Programmable Approaches

- 369 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Mechanism Design

Visual and Programmable Approaches

About this book

In the field of mechanism design, kinematic synthesis is a creative means to produce mechanism solutions. Combined with the emergence of powerful personal computers, mathematical analysis software and the development of quantitative methods for kinematic synthesis, there is an endless variety of possible mechanism solutions that users are free to e

Trusted by 375,005 students

Access to over 1 million titles for a fair monthly price.

Study more efficiently using our study tools.

Information

1 Introduction to Kinematics

1.1 KINEMATICS

Kinematics is the study of motion without considering forces. In a kinematic analysis, positions, displacements, velocities, and accelerations are calculated for mechanical system components without regard to the loads that actually govern them. In comparison to other engineering design disciplines such as statics, where motion and governing loads are considered according to Newton’s first law , and dynamics, where motion and governing loads are considered according to Newton’s second law , kinematics is the most fundamental engineering design discipline. Because it is often necessary in the design of a mechanical system to not only consider the motion of mechanical system components, but also the forces acting on them, the component material stress and strain responses to the forces (stress analysis), and the required component dimensions for the working stresses (machine design), such analyses often follow kinematic analyses.

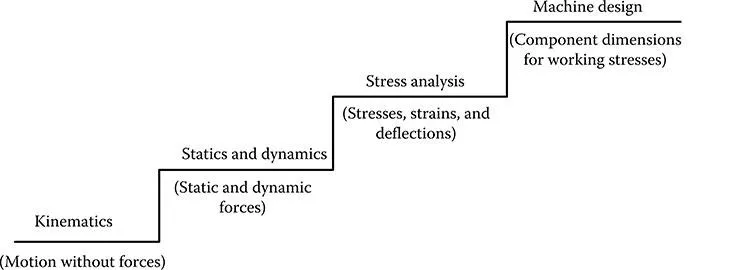

Figure 1.1 shows kinematics, statics and dynamics, stress analysis, and machine design in an ascending order of progression. This order follows the intended sequence of use of these disciplines in mechanical design. After a mechanical system has been determined to be kinematically feasible, the static and/or dynamic loads acting on the system components are considered next. After static and/or dynamic feasibility have been achieved, the stresses and strains produced in the mechanical system components are considered next. Lastly, machine design principles and methodologies are employed to ensure the material and dimensions of the mechanical system components (and subsequently the entire mechanical system) are satisfactory for the known working stresses.*

As illustrated in Figure 1.1, kinematics is the most fundamental of the listed engineering design disciplines. When a design is not kinematically sound, evidence of this will often appear in the other engineering design disciplines. For example, a discontinuous displacement profile calculated in a kinematic analysis could be revealed as excessive acceleration in a dynamic analysis, which in turn could produce excessive dynamic forces. These dynamic forces would likely produce high stresses. These high stresses may require a material selection and/or component dimensions that make the overall component design impractical for the intended design application.

In kinematic analyses, the dimensions of mechanical system components are known and the positions, displacements, velocities, and accelerations of these components are calculated. Understanding the kinematic behavior of a given mechanical system is the scope of a kinematic analysis. In kinematic synthesis, mechanical system component positions, displacements, velocities, and accelerations are known and the mechanical system dimensions required to achieve these known quantities are calculated. The objective in kinematic synthesis is to calculate the mechanism dimensions required to achieve or even approximate known quantities. Kinematic synthesis is first introduced in Chapter 4 and is covered in detail in Chapters 4 through 8.

1.2 KINEMATIC CHAINS AND MECHANISMS

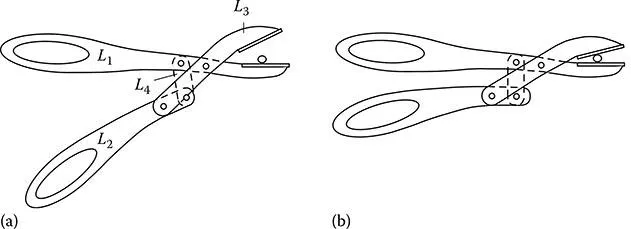

This textbook focuses on the kinematic design of mechanical systems or mechanisms as they are commonly called. A kinematic chain, an overarching classification that includes mechanisms, is an assembly of links interconnected by joints where the motion of one link compels the motion of another link (which compels the motion of another link and so on depending on the number of mechanism links).*,† Complex mechanical systems such as an automobile engine, for example, can be comprised of multiple kinematic chains while a single kinematic chain can constitute an entire mechanical system in the case of a simple tool. Figure 1.2 illustrates a commonly used kinematic chain: a pair of shears. Moving the lower shear handle (link L2) toward the upper handle (link L1) or vice versa compels the motion of the remaining links, including the cutting link L3, which results in a cutting motion. Having one link compel the motion of another link in a controlled manner is important because the fundamental objective in the design of a mechanical system is to provide a controlled output motion in response to a supplied input motion.

One characteristic that distinguishes mechanisms from other kinematic chains is that the former has at least one “grounded” link [1]. A grounded link is one that is attached to a particular frame of reference. Some mechanisms have links that are permanently grounded through friction, gravity, or coupling members (e.g., bolts and welds), whereas, with our shears example, the grounded link can be established according to one’s own preferences.

1.3 MOBILITY

The mobility or the number of degrees of freedom of a mechanism is the number of independent parameters required to uniquely define its position in space. Knowing the mobility of a mechanism is particularly important when formulating mathematical models for the kinematic analysis or synthesis of the mechanism because the models must include enough parameters to fully define the motion of each mechanism component. To fully define the position of a body in two-dimensional space at an instant in time requires three independent parameters. Considering the automobile on the road in Figure 1.3a where the road is the X–Y coordinate frame, the position of the automobile with respect to the X–Y coordinate frame can be defined given the X ...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Preface

- Authors

- Chapter 1 Introduction to Kinematics

- Chapter 2 Mobility of Mechanisms

- Chapter 3 Kinematics of Planar Mechanisms

- Chapter 4 Kinematic Synthesis and Planar Four-Bar Motion Generation

- Chapter 5 Planar Four-Bar and Multiloop Path and Motion Generation

- Chapter 6 Planar Four-Bar Function Generation

- Chapter 7 Spatial Mechanism Kinematics and Synthesis

- Chapter 8 Adjustable Planar and Spherical Four-Bar Mechanism Synthesis

- Appendix A: Solution Algorithm for Analytical Four-Position Synthesis and MATLAB® File User Instructions

- Appendix B: Solution Algorithm for Analytical Five-Position Synthesis and MATLAB® File User Instructions

- Appendix C: User Instructions for Chapter 5 MATLAB® Files

- Appendix D: User Instructions for Chapter 6 MATLAB® Files

- Appendix E: User Instructions for Chapter 7 MATLAB® Files

- Appendix F: User Instructions for Chapter 8 MATLAB® Files

- Appendix G: User Instructions for MATLAB® and SimMechanics® Files

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Mechanism Design by Kevin Russell,Qiong Shen,Raj S. Sodhi,John Q. Shen in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial Design. We have over one million books available in our catalogue for you to explore.