3D Printing for Energy Applications

- English

- ePUB (mobile friendly)

- Available on iOS & Android

3D Printing for Energy Applications

About this book

3D PRINTING FOR ENERGY APPLICATIONS

Explore current and future perspectives of 3D printing for the fabrication of high value-added complex devices

3D Printing for Energy Applications delivers an insightful and cutting-edge exploration of the applications of 3D printing to the fabrication of complex devices in the energy sector. The book covers aspects related to additive manufacturing of functional materials with applicability in the energy sector. It reviews both the technology of printable materials and 3D printing strategies itself, and its use in energy devices or systems.

Split into three sections, the book covers the 3D printing of functional materials before delving into the 3D printing of energy devices. It closes with printing challenges in the production of complex objects. It also presents an interesting perspective on the future of 3D printing of complex devices.

Readers will also benefit from the inclusion of:

- A thorough introduction to 3D printing of functional materials, including metals, ceramics, and composites

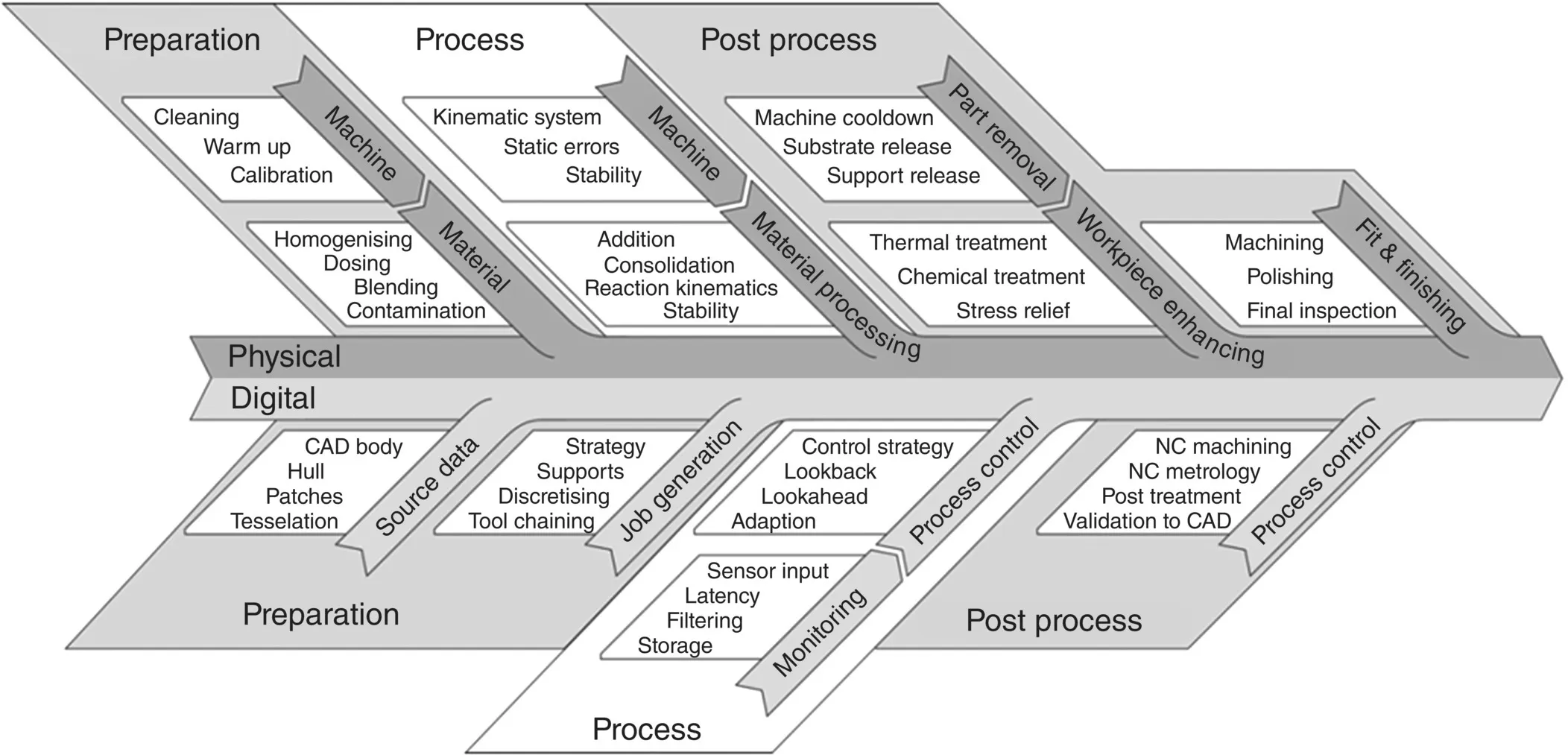

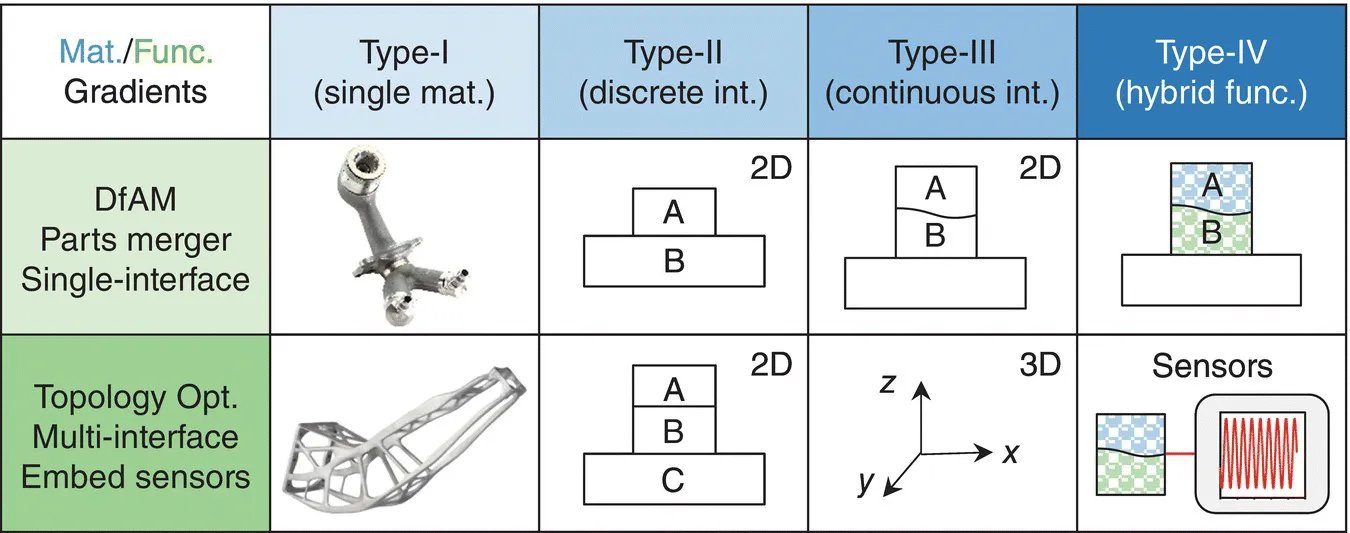

- An exploration of 3D printing challenges for production of complex objects, including computational design, multimaterials, tailoring AM components, and volumetric additive manufacturing

- Practical discussions of 3D printing of energy devices, including batteries, supercaps, solar panels, fuel cells, turbomachinery, thermoelectrics, and CCUS

Perfect for materials scientists, 3D Printing for Energy Applications will also earn a place in the libraries of graduate students in engineering, chemistry, and material sciences seeking a one-stop reference for current and future perspectives on 3D printing of high value-added complex devices.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part I

3D printing of functional materials

1

Additive Manufacturing of Functional Metals

1.1 Introduction

1.1.1 Industrial Application of Metal AM in the Energy Sector

1.1.2 Geometrical Gradients in AM

Table of contents

- Cover

- Table of Contents

- Title Page

- Copyright Page

- Dedication Page

- Contributors

- Introduction to 3D Printing Technologies

- Part I: 3D printing of functional materials

- Part II: 3D printing challenges for production of complex objects

- Part III: 3D printing of energy devices

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app