- 320 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

The story of these beloved bricks and the people who built an empire with them.

From its inception in the early 1930s right up until today, the LEGO Group's history is as colorful as the toys it makes. Few other playthings share the LEGO brand's creative spirit, educational benefits, resilience, quality, and universal appeal. This history charts the birth of the LEGO Group from the workshop of a Danish carpenter and its steady growth as a small, family-run toy manufacturer to its current position as a market-leading, award-winning brand. The company's growing catalogue of products—including the earliest wooden toys, plastic bricks, play themes and other building systems such as DUPLO, Technic, and MINDSTORMS—are chronicled in detail, alongside the manufacturing process, LEGOLAND parks, licensed toys, and computer games.

Learn all about how LEGO pulled itself out of an economic crisis and embraced technology to make building blocks relevant to twenty-first century children, and discover the vibrant fan community of kids and adults whose conventions, websites, and artwork keep the LEGO spirit alive. Building a History will have you reminiscing about old Classic Space sets, rummaging through the attic for forgotten minifigure friends, and playing with whatever LEGO bricks you can get your hands on (even if it means sharing with your kids).

From its inception in the early 1930s right up until today, the LEGO Group's history is as colorful as the toys it makes. Few other playthings share the LEGO brand's creative spirit, educational benefits, resilience, quality, and universal appeal. This history charts the birth of the LEGO Group from the workshop of a Danish carpenter and its steady growth as a small, family-run toy manufacturer to its current position as a market-leading, award-winning brand. The company's growing catalogue of products—including the earliest wooden toys, plastic bricks, play themes and other building systems such as DUPLO, Technic, and MINDSTORMS—are chronicled in detail, alongside the manufacturing process, LEGOLAND parks, licensed toys, and computer games.

Learn all about how LEGO pulled itself out of an economic crisis and embraced technology to make building blocks relevant to twenty-first century children, and discover the vibrant fan community of kids and adults whose conventions, websites, and artwork keep the LEGO spirit alive. Building a History will have you reminiscing about old Classic Space sets, rummaging through the attic for forgotten minifigure friends, and playing with whatever LEGO bricks you can get your hands on (even if it means sharing with your kids).

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Building a History by Sarah Herman in PDF and/or ePUB format, as well as other popular books in History & Architecture General. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

1891 – 1953: Bricks and Mortar

Godtfred Kirk Christiansen (1920 – 1995) may have been the person to develop and patent the famous LEGO brick design in 1958 but the LEGO story began with a different man some years before he was born. A few kilometres outside of Billund, Denmark – a town famous for its connection to the LEGO name and the original LEGOLAND theme park – in the Grene Church cemetery, is the final resting place of Ole Kirk Christiansen; Godtfred’s father and the father of the LEGO Group.

Ole Kirk (OKC) was born into poverty in the farming community of Filskov, near Billund in 1891 and went on to work as a carpenter honing the skills which would lead to the creation of wooden toys and later plastic building blocks. These intersecting bricks would inspire the development of a system of play synonymous with the LEGO name and the most popular toy of the last 100 years, according to a 2004 survey carried out by the V&A Museum of Childhood.

When the young, Danish carpenter opened his wood-working shop in Billund in 1916, a year before the town received electricity, he never expected to make his fortune in the toy business. It’s also likely that he never imagined Billund, once a town described in Henry Wiencek’s book The World of LEGO Toys as a backwater home to only a few hundred people, becoming one of Denmark’s most visited destinations. Today, Billund is home to over 6,000 people as well as LEGO headquarters, LEGOLAND Billund and the country’s second busiest airport, which was built by the LEGO Group in 1964.

Throughout the late 1920s Ole Kirk’s growing business restored old buildings, developed new structures and created goods such as ladders and ironing boards for his small community – mainly local farmers and their families. By the end of the decade he no longer worked alone but employed a small workforce. But this new business venture was not without its setbacks. And Ole Kirk demonstrated unshakeable strength of character when, in 1924, two of his sons (Godtfred and Karl Georg) accidentally set light to wood shavings in the workshop, which quickly resulted in the whole premises and the family home being destroyed by fire. This tragic accident was looked at as a reason to expand the business, and Ole Kirk had the plans drawn up for a large building that would house his new workshop and a small flat for his family. The rest of the building’s space would be rented out to provide an additional income.

Ole Kirk Christiansen (1891 – 1958)

From the age of six, Ole Kirk worked as a farmhand tending to the family’s sheep while also attending school for two days each week to learn to read and write. Whilst out in the fields the young boy would whittle wood, and so began his love for shaping and creating objects. In 1905, when he was 14 years old, he became an apprentice carpenter to one of his older brothers, Kristian Bonde Christiansen. After his training was complete he practiced his trade working in Germany and Norway between 1911 and 1916. It was in Norway where he met Kirstine Sörensen, who became his wife after he returned to central Jutland in 1916. The 25-year-old carpenter used his savings from working abroad to buy the local woodworking shop and set up his own carpentry business in Billund. He had four sons with Kirstine: Johannes, Karl Georg, Godtfred and Gerhardt, before she died in 1932. Two years later he remarried Sofie Jörgensen, with whom he had one daughter, Ulla. Ole Kirk instilled a solid work ethic in all his sons, all of whom were involved in the company from young ages, and focused on the importance of manufacturing high quality products and harvesting a good reputation over making a quick profit. Arguably, without the foundation of Ole Kirk’s teachings, which have passed on down the generations the LEGO brand would not be the international success story it is.

The LEGO Group’s headquarters in Billund, Denmark (pictured) is on the same street as Hotel LEGOLAND and LEGOLAND Billund. © Ian Greig

By the 1930s the Great Depression had begun to effect farming prices in Europe (dropping in some areas by 60 per cent) meaning Ole Kirk’s customers could no longer afford his services or products. In early 1931 Ole Kirk was forced to lay off some employees, reducing his workforce to just seven people by 1932. The business in decline, this was the year Ole Kirk started making affordable wooden toys – brightly coloured animals, piggy banks and racing cars he hoped to sell to the farming families in the area. But by the end of 1932 he faced bankruptcy and turned to his siblings for help. They loaned him money, but asked that he stop producing toys, something they saw as unprofitable. Ole Kirk continued, however, and in 1934 named the company LEGO, a contraction of the Danish phrase leg godt meaning ‘play well’.

Known locally as ‘The Lion House’ because of the two statues guarding the door, Ole Kirk’s new home and workshop, built in 1924, still stands in Billund today, and forms part of the LEGO Museum. © Ian Greig

Despite being famed for producing the plastic LEGO brick and the LEGO System, Ole Kirk’s company started out producing toys out of wood. Some reports indicate that it was the production of scaled models (for his other carpentry projects) that got him thinking about making toys, while others claim the idea was suggested to him by a social worker. Either way, soon enough miniature vehicles – cars, trains, planes and buses – began to appear among the ironing boards, step-ladders and wooden stools. These simple-looking toys may seem bulky and plain, especially by today’s standards, but they were built with the same level of skill and craftsmanship that Ole Kirk had been putting into his furniture and carpentry for years. Believing that ‘only the best was good enough’ (the company motto), even for a child’s toy, Ole Kirk’s toy manufacturing process was as meticulous as all his other work, if not more so. The birch wood used to build the toys was cut from the forest, dried outside for two years, and then dried in a kiln for three weeks before it was considered suitable for the workshop. After the toys were assembled, they were sealed, sanded and primed and finally painted three times over to produce a top-quality finish. Once, when Ole Kirk’s son Godtfred skipped a layer of painting to save money, his father ordered him to return the shipment and repaint all the toys himself, reminding his son of the importance of product quality over profiteering.

A price list from 1932 shows 28 different toys listed, including a six-wheeled school bus, a tramcar, and a lorry. It also shows that Ole Kirk continued to manufacture practical furniture and household items alongside the colourful new additions to his product line – not that the people of Billund could really afford either. While his first toy range enjoyed some success, the families in the area were poor, and would sometimes exchange food for toys rather than money. In 1932 a wholesaler went bankrupt leaving Ole Kirk with a surplus of toys. Selling them door-to-door, he even traded some toys for a sack of almonds.

The LEGO Name

In 1934 Ole Kirk held a competition to name the toy company with a bottle of his homemade wine for the winner. None of the entrants impressed him more than his own, though, so he stuck with ‘LEGO’. Ole Kirk didn’t know it at the time, but LEGO is also the Latin word for ‘I put together’ or ‘I assemble’, a definition that would come to be more than appropriate in years to come.

These trains, planes and automobiles were soon joined by a menagerie of animal creatures in 1935. From bejewelled elephants and jolly green mallards to ladybirds, squirrels and puffed up cockerels, the animal kingdom had arrived. Some of these new designs were more complicated than their transportation predecessors, especially the pull-toys, which incorporated moving parts and noise mechanisms, the patterns for which Ole Kirk carefully drew up himself. They included a man riding on a goat, which would move up and down as you pulled it along – it was based on the Hans Christiansen Andersen story Clumsy Hans – a monkey riding a car and a pony towing a brightly coloured cart. One of the most recognisable and most popular LEGO pull-toys was also one of the first. The wooden duck was sold in various incarnations for 22 years (1935 – 2957) and is typical of the wooden designs the LEGO Group produced during the 30s and 40s. As it moves along on wheels its beak opens and closes, while the base includes a mechanism that ‘quacks’ at the same time. Because of the expanding workload the painting of early LEGO ducks was contracted out to locals. In the 1940s TLG started stencilling the ducks instead to save time and labour costs. Because of this and its longevity, the LEGO wooden duck is available in hundreds of variations.

One of the original wooden ducks is proudly displayed at the LEGO Museum in Billund. © Alex Howe

Over the next 28 years TLG manufactured not only wooden toys but also a variety of other wood-based products. In one 1950s LEGO catalogue there are 120 products listed (over two hundred designs were produced in total), and while there are the expected wooden animals, trains and trucks, there’s also an abacus, a skipping rope and a dustpan and brush. The company also made doll buggies, wheel barrows, chalk boards and coat hangers designed by Dagny Holm (Ole Kirk’s cousin, who would go on to be one of the chief designers of LEGOLAND Billund). These toys may have been a diversion from the carpentry work Ole Kirk had trained for, but they were not that unusual when compared to the toys being produced by other European toy makers at the time. Prior to the Twentieth Century Germany had been the epicentre of toy manufacturing, and one particular village, Seiffen in the Ore Mountains region of Saxony, was renowned for its production of detailed wooden toys and traditional Christmas figures and decorations, which were, and still are, exported all over the world.

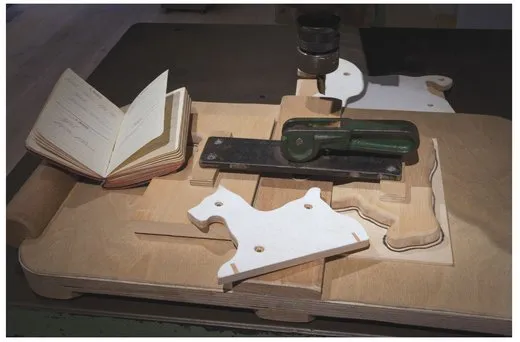

This manual wood-working machine, on display at the LEGO Museum, enabled Ole Kirk to mass-produce parts for his wooden toys, later these were replaced by electric machines. © Alex Howe

As a small company with just ten employees in 1939, the LEGO Group had tough competition from these and other imported toys. Despite the fact that LEGO wooden toys were never sold outside of Denmark (with the exception of some sales in Norway), the company wasn’t immune to the trends and crazes of the toy industry. A popular and well known LEGO story is that of Ole Kirk’s brush with the yo-yo. In the mid-1930s, the demand for yo-yos was at an all-time high in America after Duncan Toys took over a Californian yo-yo manufacturing company and began promoting yo-yo contests. The craze soon found its way to European shores, especially after the first World Yo-Yo Competition was held in London in 1932. Fully equipped to deal with the demand for the little wooden toys, Ole Kirk set about producing a large supply for Danish children, but as all crazes soon do, this one died out, leaving Ole Kirk with a huge surplus of yo-yos he was unable to sell. He struck on a great idea – turn the yo-yo discs into wheels for his toys including a brand new toy truck, and his thinking paid off – the truck was a success. This was an important lesson for the toymaker, and for the company, which avoided following popular trends and toy crazes for many years to come. He learnt the importance of innovation and originality over following in the footsteps of other manufacturers, and perhaps the most important point of all: If you want to have longevity, and customers who keep coming back for more, you have to sell them a toy that has endless possibilities.

Despite a factory fire in 1942, the LEGO Group continued to grow and to produce wooden toys even after the introduction of plastic toys in 1949. In fact plastic and metal were incorporated into some of the designs – see Monypoli below. Unfortunately, as the company’s plastic toy line developed and aligned itself with the large-scale manufacturing of the future of toys, the sales of the wooden line peaked in 1952, and remained slow thereafter.

Monypoli

Monypoli might sound similar to the Parker Brothers/Hasbro property game Monopoly, but there were no Scottie dogs, fake money and definitely no jail to be found on this board. This road safety game was the first board game produced by the LEGO Group and until very recently remained the only one. Released in 1947 it included a game board, a traffic sign instruction poster, game cards, a die and cup, small metal cars and wooden circular tokens. Although TLG did not revisit board game manufacturing – with the exception of licensed products – for many years to come, the motifs of road safety and traffic police were incorporated into the construction system that was developed a few years later.

As Bill Hanlon explains in his 1993 book Plastic Toys: Dimestore Dreams of the ’40s and ’50s, it’s hard to imagine the world around us without plastic. Over sixty years of development and manufacturing has resulted in the abundance of safe plastic-based toys we know today, and the LEGO Group is an important part of that history. There was a surge in the use of plastic injection-moulding during World War Two because of the increase in demand for mass-produced and affordable items. Unlike wood or metal toy production, where fine details were costly to include and uniformed precision was harder to achieve, injection-moulding provided the toy industry with a cheaper product that was faster to produce. As Hanlon explains, the advantages were many. Colour could be added to the cellulose acetate granules (the type of plastic originally used by the LEGO Group), rather than painting the toys after moulding, meaning the colour could not chip or peel; plastic was relatively strong and did not splinter like wood; transparent parts, such as car windshields, could be added in plastic; they were also far more hygienic than their wooden counterparts. Perhaps one of the most fundamental differences between the two types of manufacturing was the fact they were usually lighter and therefore cheaper to ship on a large scale. This cost difference was passed on to the consumer, meaning children were able to save whatever small amount of money they had to buy cheap plastic toys.

The LEGO Group joined the world of plastic toys in 1947, when it became one of the first companies in Denmark to own an injection moulding machine. Ole Kirk saw a real future in plastic toys, and had wanted to buy three machines, but at 30,000DK each his family managed to persuade him to wait until they were certain the investment would pay off. But Ole Kirk had been keeping his eye on the industry and saw how plastic toys were beginning to become more available across Europe – and the reaction was positive. The company spent two years creating designs and moulds and in 1949 released the first of their plastic toys. These included a plastic rattle shaped like a bloated fish designed by Godtfred Kirk Christiansen. The toy was made by fusing two mirror-image pieces together. Many different coloured plastic granules were mixed before heating, so the rattle was available in a huge variety of colour patterns. The details (eyes, fins, lips) were hand painted on afterwards with the same level of quality and precision already associated with LEGO toys.

One of the earliest injection-moulding machines with teddy mould on display at ...

Table of contents

- Dedication

- Title Page

- Copyright Page

- Acknowledgements

- NOTE FROM THE AUTHOR

- Table of Contents

- In The Beginning . . .

- Chapter 1 - 1891 – 1953: Bricks and Mortar

- Chapter 2 - 1954 – 1977: Systematic Success

- Chapter 3 - 1978 – 1988: The Golden Age

- Chapter 4 - 1989 – 1999: It’s a LEGO World

- Chapter 5 - 2000 – 2011 Foundations for the Future

- Chapter 6 - Building Outside the Box

- Bibliography

- Photo Credits

- Index