Digitalization and Analytics for Smart Plant Performance

Theory and Applications

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

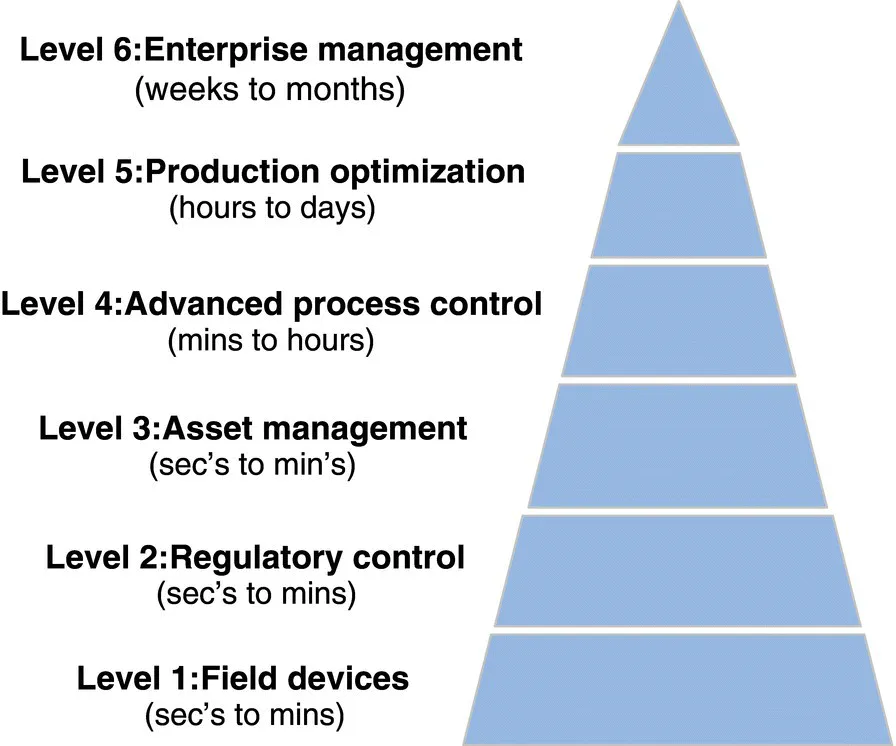

This book addresses the topic of integrated digitization of plants on an objective basis and in a holistic manner by sharing data, applying analytics tools and integrating workflows via pertinent examples from industry. It begins with an evaluation of current performance management practices and an overview of the need for a "Connected Plant" via digitalization followed by sections on "Connected Assets: Improve Reliability and Utilization, " "Connected Processes: Optimize Performance and Economic Margin " and "Connected People: Digitalizing the Workforce and Workflows and Developing Ownership and Digital Culture, " then culminating in a final section entitled "Putting All Together Into an Intelligent Digital Twin Platform for Smart Operations and Demonstrated by Application cases."

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

PART 1

CHALLENGES AND OPPORTUNITIES FOR DIGITALIZATION

1

CHALLENGES FOR OPERATION EXCELLENCE

1.1 INTRODUCTION

1.2 OPERATION ACTIVITIES IN A PROCESS PLANT

Table of contents

- COVER

- TABLE OF CONTENTS

- TITLE PAGE

- COPYRIGHT PAGE

- DEDICATION

- PREFACE

- ACKNOWLEDGMENTS

- PART 1: CHALLENGES AND OPPORTUNITIES FOR DIGITALIZATION

- PART 2: MODEL THINKING FOR SMART OPERATIONS

- PART 3: CONNECTED PLANT FOR SMART OPERATIONS

- PART 4: DIGITAL SOLUTIONS FOR SMART OPERATIONS

- INDEX

- END USER LICENSE AGREEMENT