Some Background

I retired after a nearly 20-year career at Toyota's US headquarters in Torrance, California. Let me state clearly at the outset, I refer to my time there as a 20-year internship. Working at Toyota was not easy. But for me it was an intense but richly rewarding experience which profoundly changed me and my perspective on leadership.

After leaving Toyota, I spent the remainder of my career teaching lean and translating it into other industries and business realms as both a private consultant and full-time employee serving in internal, lean-leadership consultant roles.

Who cares about Toyota? Most writers, speakers and other experts would quickly acknowledge that Toyota is the Mecca for lean practitioners. Almost every book out there says so. Toyota, I discovered, is a very different kind of place. Since I worked in Aerospace and other companies, public and private, prior to my immersion at Toyota, I had an up close and personal comparison of normal or traditional companies to Toyota.

To say that it was a culture shock is an understatement of epic proportions. Toyota seemed like such a weird place at first. Nothing seemed familiar. But slowly I learned and began to appreciate the culture and learned their language along the way. As I taught it to others, I eventually came to understand it myself even more deeply. Personally, I never want to work in a ‘traditional’ job or a ‘normal’ company again. Soon you will appreciate why.

One of the key roles I undertook with my colleagues while at the University of Toyota was the design, creation and deployment of a lean curricula that could be used anywhere, not just in manufacturing or production. We were commissioned by our parent company in Japan to do just that.

We designed a systematic process to assist any organization in any industry, beyond the factory floor, to maximize the potential benefits of a lean culture. Together we crafted a three-part approach to launch lean into new Toyota companies and divisions and for its suppliers and partners as well as other organizations far and wide. We also coined new terms and new methodologies that industry has now widely embraced.

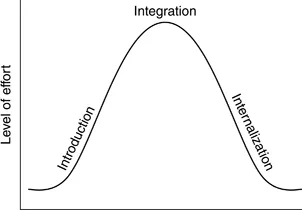

To simplify our approach, we went back to basics. We divided the lean transformation process into three high-level strategic steps or ‘phases’: Introduction, Integration and Internalization. We framed it as the I-3 approach. The first, and by far the most important, part of this book is aimed at the Introduction phase, which we will dive into deeply.

Since we will be exploring this topic from a strategic vantage point, most of the nitty gritty, tactical work won't be covered in much detail here. This book is aimed primarily at top executives, and therefore the information is presented in executive summary form. The necessary details and specific action plans will come together with your team, probably with strong elbow-coaching support later. For now, stay focused on the long-term vision and strategy and avoid getting mired in the details.

This first part will help you figure out what lean is all about, how it might benefit you and your organization and how to avoid the major pitfalls many have fallen into. A word of caution, there is a lot of misinformation out there about lean and lean leadership. There are also highly exaggerated claims about its benefits, too. I encourage you to study these claims for yourself. As you explore other resources, check the credentials of their authors and consulting firms carefully! I will guide you on the best way to choose your partner(s) in this journey.

As the title implies, over many years of doing this, I have developed what I call my “Napkin Series” of lean leader education and executive coaching. Quite literally, these are the simple ways I use to help people, especially top leaders, understand lean by drawing simple sketches on napkins, paper towels, business cards, corners of tablecloths and the like. These drawings are not highly polished works of art. They have been created in very spontaneous ways.

I have drawn these crude sketches on picnic tables, car roofs and pickup truck hoods. It has evolved from countless lunch, dinner and happy hour coaching sessions when the only tools available were a napkin and a pencil. For the record, pencils are good; crayons are better.

In addition to explaining the core foundational elements of lean, I will also offer you some quick and easy ways to help you explain it to others. By the way, none of my sketches are copyrighted and all are intentionally easy to replicate. That is the point. You should be able to easily redraw them yourself to help you coach your own team through the process. Some of my sketches or similar versions have been inspired by or been passed on to me by my own mentors, but they aren't captured or catalogued anywhere else to my knowledge.

Two future parts in this series will cover Integration and Internalization in somewhat less depth but here we will give you a peak over the horizon to see what's coming if you decide to take the leap. However, when appropriate, you will see references made to the other phases throughout.

Note: Beware of slick PowerPoint presentations that offer to “introduce you to lean”. They have their place but when the lights go down during a presentation, many people unconsciously slip into silent resistance mode. Some people are completely turned off by this ‘sales job’ approach.

While not necessarily a showstopper, most of my clients' decisions to dive into lean are traceable back more to our casual and frequent one-on-one discussions than they are from any formal presentations. Yes, there is a place for formal presentations, perhaps to the board of directors or large employee gatherings, but person-to-person dialogue is usually the best option in dealing with top executives and other key stakeholders, especially early on. See also “Nemawashi” in Chapter 4, “Lean Speak”.

Let's keep it real; this is a big undertaking. It is not to be feared but to be approached as you would anything that has major culture change initiatives attached to it. Don't rush into it and don't expect to make a quick decision as to whether to adopt lean as your organization-wide operating system or cultural transformation process. And don't just jump into a new leadership style without a plan unless you want to freak out everybody with the ‘new you’.

Take your time and do your homework. Research, study and collaborate with your executive team, other peers and your lean consultant(s) before you make a go/no-go decision. Keep in mind that within the locus of lean consultants, there are specialists of every description (i.e., manufacturing, supply chain, service industries, banking, finance, law enforcement, etc.). Your primary “lead” consultant will be like your primary physician who has multiple specialists at his/her disposal and can call on them or refer them to you as needed.

It goes without saying that I STRONGLY recommend partnering with a seasoned external coach! Don't go it alone! You wouldn't try to fly an airplane without an instructor first, would you? The investment you make in the early days of this journey will pay dividends quickly and can help you avoid costly mistakes down the road.

A Word about Cultural Transitions

I worked for many years and indeed had a ten-year second career in the healthcare industry. When we talk about cultural transitions, keep in mind that we are describing manifestly different ways of working.

One clear healthcare example of this is the Herculean transition from converting huge stacks of paper medical records to electronic medical data (EMR) data storage. Of course, the latter had enormous potential benefits, but the task to switch from old to new inspired all new dedicated industries just to help to bridge the transformation process. That conversion was daunting to say the least! Not an easy decision to be sure.

You should approach this transition with the same rigorous research, planning, realism and thoughtfulness that would be appropriate for any such large-scale effort. In the words of Ben Franklin, “Make haste slowly”. Converting from a traditionally managed culture to a lean culture should be undertaken with clear-eyed realism of what is really involved and a very clear understanding of how it may affect you, your company and your leadership staff specifically.

It is worth noting that some think that they can just dabble in lean or just try out a few lean tools here and there. A simple Google search on lean tools will absolutely inundate you with possibilities. Sure, those that choose this approach are likely to pick up some short-term gains, but ‘tool junkies’ won't achieve the real potential of lean this way. Applying tools without the cultural underpinnings will result in disappointment, failure and cynicism.

The real problem here is that people tend to THINK they have ‘adopted lean' by mimicking readily available lean tools. This is an illusion. Imagine trying to grow corn on the freeway. It doesn't matter how good the seeds are, they can't thrive in that condition. Just “planting” tools in the wrong organizational environment will likely have the same end result.

Some who have tried this approach have also fallen into the illusion of progress with lots of the trappings of lean and busy people conspicuously driving improvement events, having seminars, etc., but you will never achieve the full benefits of lean this way! It is like the saying that, if you vote, you therefore have a democracy! They vote in Iran, Venezuela and China, right? Copying behaviors without the culture to sustain them will fail. Once again, your primary coach will help you avoid this common trap.

So, putting up lean posters all over the place, developing slogans, having meetings, rallies, marketing projects and the like will only give you the appearance of a lean culture! This pseudo lean approach is like the difference between cheap chrome plate and sterling silver. It looks shiny at first, but the luster will eventually fade and peel away. Worse, in tough times, when resources are scarce, this is often the first place executives will look to cut costs.

By comparison, true lean organizations will invest more heavily in tough times because they realize the potential to survive may actually depend on the lean culture they have created. Think of it as a kind of organizational insurance. Even in tough times, you wouldn't cancel your fire insurance policy, would you?

But here is the good news: There ARE methods that will allow you to experiment, compartmentalize and learn quickly without committing to or driving an organization-wide transformation. It can be chunked up to make it far easier to implement. You may even isolate a specific department or unit with end-to-end process responsibility as a good place to start.

An example might be in HR in the recruiting process. Theoretically, they have complete responsibility to improve their work streams without very much spill over into other areas. These are great places to start. This will also help you to minimize the sticker shock when approaching the board of directors (BOD) and your chief financial officer(CFO).

This smaller scale “test of change” can be highly effective, especially if the process is articulated as part of a long-term, crawl-before-you-walk strategy. Check out the section on “model cells”. For what it's worth, my favorite word in the lean vocabulary is “experiment”. Soon you will appreciate why. More on this later.

One final note: As stated earlier, none of what I am offering here is copyrighted even though it is primarily my own original work. I am at a point in my life where I just want to leave a positive legacy and “leave it all on the field” so to speak. Nothing more.

I simply want you to learn and to use this methodology. Why? I think you will see that once lean leadership is properly understood, demystified and deployed, it can and will dramatically improve and strengthen your organization and change lives (especially yours) for the better. It did mine.