Chapter 1

The Ground Breakers

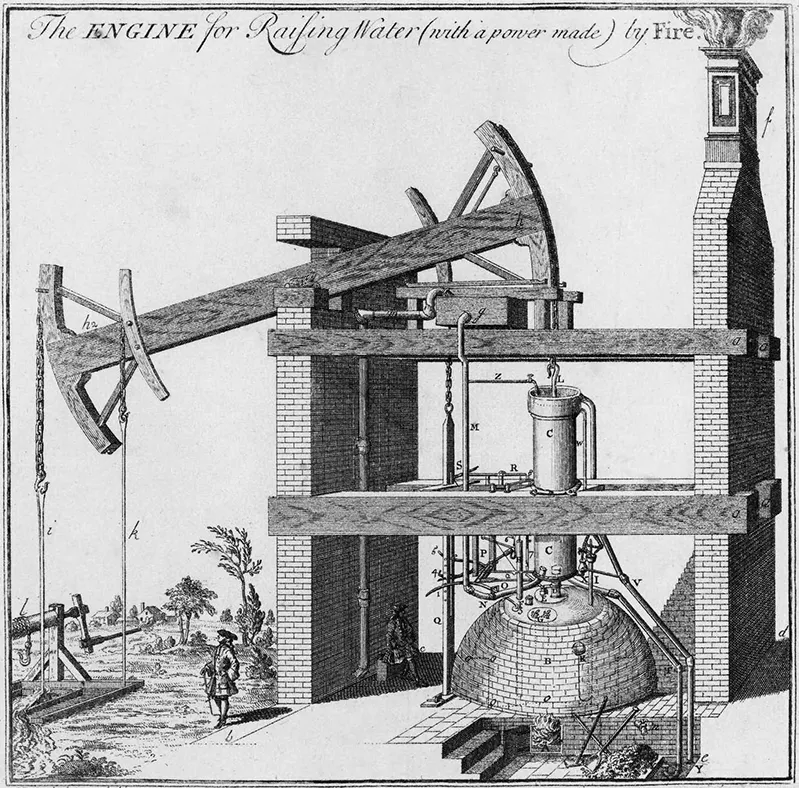

Newcomen’s Engine for Raising Water … by Fire, from 1717.

Thomas Newcomen, 1664–1729

In the field of steam power used in eighteenth-century industry, James Watt stands pre-eminent. His is a household name, and it is easy to assume that he was not only the first man to harness steam power effectively, but that his invention came out of nowhere, and then became universally accepted. This was simply not the case, and indeed during the period up to 1800, when the Watt patent expired, only some 450 out of 2,200 steam engines made in Britain followed the designs of James Watt. A far greater number followed the designs of an unsung predecessor, the remarkable Thomas Newcomen. His machines may have been more basic, less powerful and less fuel efficient – but they remained popular because they were cheaper to produce and simpler to maintain.

Newcomen engines dominated the marketplace for three quarters of a century. They were undoubtedly inefficient, unsophisticated and required large quantities of coal. While this may not have been a problem when the machines were being used to pump out water from coal mines, it was a major factor for mine owners in areas such as Cornwall, where metals such as tin and copper were mined and where coal was absent. This meant that coal had to be brought to the site – at considerable expense.

Of course the Watt engine, with its separate condenser, was a technical revolution, but that should not mean that Newcomen is denied credit for paving the way; for bringing into production the first effective steam engine, way back in 1712.

Thomas Newcomen was born in 1664, to a family of merchants in Dartmouth. This Devon town was close to the various mining villages dotted around Dartmoor, and also gave access to the copper and tin mines which dotted the countryside in the adjoining county of Cornwall. This was Newcomen’s ‘patch’, which he would have travelled around as a young man, promoting the ironmongery business which he started in around 1685. Before that, Newcomen had been apprenticed as an engineer in the county town of Exeter.

The young Newcomen would have been well aware of the problems faced by mine owners in trying to prevent mine shafts flooding. Traditionally this meant trying to bale out the flooded mines with buckets, pulleys and ropes. Horse power and manual labour were the only two viable alternatives, although wind power had also been tried, using windmills erected immediately at the head of the mine shaft.

As a young adult Newcomen was selling equipment from his ironmongery shop aimed at helping these mine owners. He did not just sell products made by others – he listened to the mine owners and engineered items specifically for their needs. He was a good engineer, a good listener and a good problem-solver. Like so many of the men featured in this book, Thomas Newcomen was a Dissenter – he was a devout Baptist and a lay preacher. Not only did this mean that he was ‘driven’, but also that he was unfettered by prevailing views, unwilling to accept that things could not be changed, or that ‘this is the way things are: accept it’. Conformity – to Church of England ideas and to mainstream thinking – seemed to suffocate others, whereas Nonconformists were willing to challenge, to embrace new ideas and, in that ghastly modern phrase, to think outside the box. This entrepreneurial spirit dominated so many of the earlier inventors and advocators of change and Newcomen was no exception.

He was not by any means the first to advocate steam power. Early attempts had been made by men such as Edward Somerset, Thomas Savery and Denis Papin. They had all worked on various schemes to use fire to heat water in order to create a vacuum. Most of these early ideas remained simply that – ideas. What Newcomen did was to put them into practice – to make a machine which could be taken to the head of the mine, erected, fired up, and then used to pump water.

Probably because Cornwall had no coal to fire up the engine, the early experiments took place not where Newcomen lived, but close to the collieries of the Midlands and as far north as Yorkshire. The first may well have been at Griff colliery in Warwickshire (1711); followed up by installations at Bilston in Staffordshire (1714); at Hawarden in Flintshire (1715); at Austhorpe in West Yorkshire (1715) and at Whitehaven in Cumberland (1715).

At this stage Newcomen was in partnership with another Dartmoor resident, a man called John Calley (variously described as a glassmaker and a plumber). Much of their experimentation was ‘hit and miss’ – they were not developing a well-researched theoretical concept based on detailed figures and calculations, and it was a case of trying different ideas until they found one which worked. In practice, Calley disappeared from the scene before he could see the success of their venture – he died in 1715.

The following year Newcomen was granted a patent for his steam-driven pumping engine. The London Gazette reported:

Whereas the invention for raising water by the impellant force of fire, authorized by Parliament, is lately brought to the greatest perfection, and all sorts of mines, etc., may be thereby drained and water raised to any height with more ease and less charge than by the other methods hitherto used, as is sufficiently demonstrated by diverse engines of this invention now at work in the several counties of Stafford, Warwick, Cornwall, and Flint. These are therefore, to give notice that if any person shall be desirous to treat with the proprietors for such engines, attendance will be given for that purpose every Wednesday at the Sword Blade Coffee House in Birchin Lane, London.

In practice the partnership of Newcomen/Calley must have been working on the experiments for some years. A Swedish visitor to England by the name of Marten Triewald wrote in 1717 to describe his acquaintanceship with the pair of inventors – he had apparently observed them assembling their ‘fire machine’ at Byker Colliery near Newcastle upon Tyne. In his words:

Now it happened that a man from Dartmouth named Thomas Newcomen, …. made up his mind in conjunction with his assistant, a plumber by the name of Calley, to invent a fire machine for drawing water from the mines. He was induced to undertake this by considering the heavy cost of lifting water by means of horses, which he found existing in the English tin mines. These mines Mr Newcomen often visited in the capacity of a dealer in iron tools with which he used to furnish many of the tin mines … For ten consecutive years Mr Newcomen worked at this fire-machine.

What comes across was what a thoroughly decent man Newcomen was; mine owners wrote of his scrupulous business arrangements and his unfailing honesty. Many of these owners may have been fellow-Baptists – they trusted Newcomen and they swiftly spread word of his ‘fire machines’ among other owners. In a comparatively short time, over 100 engines had been put to use. At that stage they had limited effectiveness in that they could only operate in comparatively shallow mine workings, at a time when mine owners were driving ever-deeper shafts.

Perhaps it was his innate decency that meant that Newcomen was willing to pay Savery’s estate a share of the profits, choosing not to argue that there were significant differences between his own invention and the one described in Savery’s patent nearly twenty years earlier. Savery had demonstrated his ideas to the Royal Society in 1699 having taken out a fourteen-year patent the year before, covering his invention for ‘raising water and imparting motion to all sorts of mill-work by the impellant force of fire, useful for draining mines, serving towns with water and working all kinds of mills in cases where there is neither water nor constant wind.’ This patent was then extended by twenty-one years, expiring in 1733. Newcomen accepted that Savery had appeared first on the scene. Presumably he would have known Savery, who lived at Totnes just a few miles from Newcomen’s hometown. No matter that Savery had never successfully produced a working example, or that one of his attempts caught fire and exploded. No matter that it was Newcomen who added the ‘missing ingredient’ – a way of condensing the steam in the cylinder by injecting cold water from an external tank. No matter that in order to work, the Savery design would have had to go beyond the limits of seventeenth-century technology. Also, Savery’s machine could only have pumped water from a depth of 30ft, whereas Newcomen’s development meant that the machine could be used to pump out 10 gallons of water every minute, from a depth of up to 156ft.

Despite these obvious differences, the upshot was that instead of litigation and rancour, an unincorporated company called ‘The Proprietors of the Invention for Raising Water by Fire‘ was formed to share the profits, and it pressed ahead with a series of installations and improvements. Even after the ideas of James Watt and John Smeaton had led to radical improvements to steam engines, the basic Newcomen engine remained in use, for many years, the ‘workhorse’ of the first part of the Industrial Revolution. Many were adapted to incorporate Watt’s idea for a condenser – giving rise to a hybrid described as a ‘pickle-pot’ condenser. In all, it is thought that some 2,000 Newcomen engines were sold in England and on the Continent during the eighteenth and nineteenth centuries.

Newcomen had married in 1705, when he was 41. His bride was another Devonian, one Hannah Waymouth. She bore him three children, all of whom reached adulthood. Although little is known about his later years, Newcomen remained active in promoting his engines, before finally dying, in London, on 5 August 1729. He was buried in the Dissenters Burial Ground at Bunhill Fields – the same cemetery where the mortal remains of other prominent Nonconformists, such as Daniel Defoe, William Blake and John Bunyan, are interred.

There is no gravestone marking Newcomen’s burial, no impressive mausoleum telling the world that a great man lies buried beneath. In a way, that sums up Thomas Newcomen: a thoroughly worthy, honest guy who was pleased to help mine owners cope with a problem which was affecting their business; who counted his clients as his friends, and who recognised that he was just one part of a jigsaw. He was no Arkwright, claiming credit for the inventions of others. He never achieved great fame in his lifetime, and nothing suggests that he lived an opulent lifestyle or died rich. His children achieved solid middle-class respectability: one developing a business making serge cloth (used in making military costumes, trench coats and so on); another running an ironmongery shop; and another marrying a surgeon. Newcomen played a crucial part in ‘getting the ball rolling’. His atmospheric engine was not perfect, but that alone inspired others to make improvements and to give impetus to the Industrial Revolution.

A modified version of the Newcomen engine is still on display in Dartmouth, albeit using hydraulic rather than steam power, and there is another in the Science Museum. Various others can be found elsewhere in museums both in Britain and overseas.The Newcomen Society does its best to maintain and promote Newcomen’s reputation and in 2012 the Royal Mail brought out a stamp featuring Newcomen’s steam engine as part its ‘Britons of Distinction’ series.

Richard Trevithick, 1771–1833

It was Christmas Eve, 1801 and a large crowd had gathered in the Cornish town of Camborne. The stretch of road running up from Tehidy Road and along Fore Street was known as Camborne Hill, and the crowds watched in amazement as a noisy, steam-belching leviathan called ‘Puffing Devil’ moved slowly up the ascent, turned round, and then came back down again. The excitement of the occasion was described by a local cooper, Stephen Williams, who was to write later:

‘Twas a stiffish hill going from the Weith up to Camborne Beacon, but she went off like a little bird. When she had gone about a quarter of a mile, there was a roughish piece of road covered with loose stones; she didn’t go quite so fast, and as it was flood of rain and we were very squeezed together, I jumped off. She was going faster than I could walk, and went on up the hill about a quarter or half a mile farther, when they turned her and came back again to the shop.

The event was commemorated in the song Camborne Hill:

Goin’ up Camborne Hill, coming down

Goin’ up Camborne Hill, coming down

The horses stood still;

The wheels went around;

Going up Camborne Hill coming down

It is a song still associated with Cornish prowess – especially on the rugby field – and is one of the most lasting tributes to a man who died a pauper, and yet was a real pioneer of the Industrial Revolution. His name – Richard Trevithick – is little known nowadays, and as any schoolboy will tell you, the inventor of steam locomotion was not Trevithick but father and son George and Robert Stephenson. Actually, that is not correct. The Stephenson ‘Rocket’ may be renowned the world over, whereas Trevithick’s ‘Catch-me-who-can’ engine is hardly remembered. Yet it was the first in the world to carry fee-paying passengers, in 1808. The ‘Rocket’ is rightly famous for having won the Rainhill Trials held to decide the best design for an engine to run along the Liverpool–Manchester line. Yet that was in 1829, a quarter of a century after Trevithick had pioneered the use of a high-pressure steam engine to provide locomotive power. Trevithick’s invention came first, and he deserves far more credit for his inventiveness and his dogged determination. Indeed, he can be seen as one of the first of a breed of heroic failures littering the story of modern progress.

Trevithick was a gentle giant of a man – well over 6ft tall, born in the parish of Illogan in Cornwall in April 1771 and educated – somewhat sparsely – at a local elementary school. At school, when he bothered to turn up, he developed a reputation for cussedness and disobedience. Nowadays he would probably be diagnosed as having Attention Deficit Syndrome, not least because he was actually quite bright, quick witted and good with figures. As the youngest of six children born to a Cornish mining family, his horizons must have appeared to be limited to the local mining community – and yet he turned out to be able to fly much farther afield. He was generally popular as a youngster and earned the nickname of the Cornish Giant because of his size and strength. What also singled him out was that he was an extremely practical man – good at problem solving. It was a time of great opportunity in the Cornish mining community, not least because after 1800 the patents taken out by James Watt had expired, meaning that mine owners were free to make their own experiments to adapt and improve on the existing machinery. In this environment Trevithick was able to spend time tweaking and altering the existing machines, improving their fuel efficiency and thereby reducing running costs. He was soon in high demand throughout Cornwall, where he was looked on as something of a local hero – a man who was soon in direct competition with the ‘outsider’ James Watt, who was keen to avoid losing his dominance in the manufacture of pumping machines.

Watt had always championed low-pressure engines – they were cheaper to produce, less temperamental and indeed less likely to explode. They were also virtually silent because they relied on condensing steam to produce a vacuum. Trevithick was determined to develop a high-pressure machine, with the advantage that it used far less coal and hence was particularly appropriate to be used in Cornwall as it reduced the need for transporting coal from far afield. It introduced to the world the noise of steam escaping rhythmically – giving rise to the name of ‘puffer’ for his machines. These machines were initially used as static engines operating winding gear. There were occasional problems, such as in 1803 when one of Trevithick’s high-pressure engines exploded. Such instances were immediately seized upon by Watt, and by his partner Matthew Bolton, as evidence of how pressurised steam was inherently dangerous. Undeterred, Trevithick set about introducing safety features and modifications. His experiments culminated in the production of what became known as the ‘Cornish boiler’ – using a horizontal cylinder with a single fire-tube running through the centre. It is sometimes referred to as an internally fired boiler, and in its basic form, it remained in use well into the twentieth century. Trevithick was not the only pioneer to try and harness power using high-pressure steam – but he was the first to do so successfully in an industrial context. His were no theoretical examples – they actually worked.

Meanwhile, Trevithick also worked on the idea for an engine which could drive wheels, generating locomotive power – hence the Camborne Hill experiment in 1801. It was not wholly without incident – the drivers apparently were so pleased with their efforts that a couple of days later, having driven down Camborne Hill, they retired to the local hostelry to celebrate, leaving the steam engine unattended and without topping up the water levels. While they quaffed their ale and ate their Christmas goose the engine overheated, caught fire and was seriously damaged. Undeterred, Trevithick applied for, and obtained, a patent for his steam locomotive in March 1802. The next year saw a Trevithick locomotive, known as the London Steam Carriage, being demonstrated in London to astonished onlookers. It ran between Holborn and Paddington. It was however far too heavy for the ground over which it travelled and had the added disadvantage of being uncomfortable for passengers and, even worse, was more expensive than travelling by horse.

More tragically, in 1803 another of Trevithick’s machines was being demonstrated in Greenwich when an explosion occurred, killing four people.Trevithick responded by developing safety valves to prevent the build-up of excessive pressure, as well as a manometer so that the operator could read the pressure inside the boiler.

Trevithick then took a job as engineer at Penydarren ironworks, near Merthyr Tydfil. In early 1804 he started to experiment with an engine towing wagons, culminating in a trial on 21 February when his engine hauled a 10-ton load of iron for a distance of 9½ miles over a period of slightly more than four hours. The average speed – at around 2½ miles an hour – may not seem impressive, but it established for the first time that steam locomotion was feasible and could be used to move significant amounts of freight. Trevithick was to write of the events of that day:

… yesterday we proceeded on our journey with the engine, and we carried ten tons of iron in five wagons, and seventy men riding...