eBook - ePub

Ultimate Guide: Plumbing, Updated 5th Edition

This is a test

Share book

- 250 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Ultimate Guide: Plumbing, Updated 5th Edition

Book details

Book preview

Table of contents

Citations

About This Book

Be your own plumber and make DIY repairs and improvements! This best-selling guide on plumbing will teach you everything you need to know, from fixing a leaky faucet to making renovations, installing plumbing fixtures, and so much more. Updated with new code-compliant techniques for 2021, plus a new section on air gap fittings.

Frequently asked questions

How do I cancel my subscription?

Can/how do I download books?

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

What is the difference between the pricing plans?

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

What is Perlego?

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Do you support text-to-speech?

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Is Ultimate Guide: Plumbing, Updated 5th Edition an online PDF/ePUB?

Yes, you can access Ultimate Guide: Plumbing, Updated 5th Edition by in PDF and/or ePUB format, as well as other popular books in Tecnologia e ingegneria & Commercio tecnico e manifatturiero. We have over one million books available in our catalogue for you to explore.

Information

PART I: Projects,

Improvements, Repairs

1

working with

water

piping

COPPER WATER PIPING

STEEL PIPING

PLASTIC WATER PIPING

IN-LINE WATER-CONTROL VALVES

UTILITY FAUCET VALVES

REGULATORS & SAFETY VALVES

PEX WATER TUBING

THE TYPICAL HOME PLUMBING SYSTEM may appear to be a jumble of different size pipes running in all directions. But there is a logic to a well-designed system that almost anyone can learn to understand. The easiest way to approach the task is to separate the incoming water pipes from the outgoing drainage pipes. For an overview of how water piping and drainage systems work together, see Chapter 11 “Plumbing Basics,” here. This chapter will cover working with water piping to help you get started with making repairs and adding new plumbing fixtures.

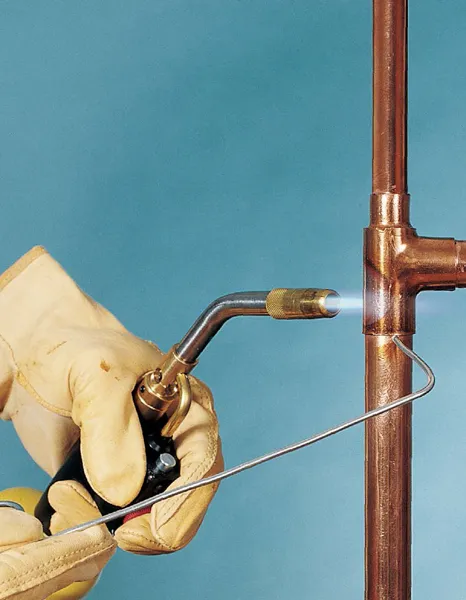

One drawback to working with water piping might be the water-pipe joining method. Most water pipes are made of copper, which must be soldered. Well-soldered joints require some skill, but with practice and the information in this chapter, good soldering technique is not beyond your reach.

Of course, you might worry about leaks, but leaks are fairly easy to repair. Just drain the system, and redo the offending fitting. It may be inconvenient and time-consuming, but it’s not difficult.

Plastic water pipes rely on a solvent for attachment. This is a skill that is easy to master. The problem is that many codes restrict plastic to drainage systems.

Cross-linked polyethylene (PEX) is an alternative that has shown tremendous growth in the plumbing industry. These systems use crimp-ring and barbed fittings for joining pipe that are easy to master.

COPPER WATER PIPING

Copper piping for water supply is available in two forms—rigid, or hard tubing, and drawn, or soft tubing. Rigid copper comes in 10- or 20-foot lengths, while soft copper comes in 60-, 100-, and 120-foot coils. You typically use rigid copper for in-house, above-concrete water-piping installations, and soft copper for belowground applications and for connecting stub-outs with faucets. Along with black steel pipe, some codes allow the use of soft copper for both natural gas and propane piping.

Rigid copper is available in Type M and Type L wall thicknesses. Type M, thinner than Type L, is used predominantly in residential systems. Type L is more common in commercial installations. Soft copper comes in Type L and Type K wall thicknesses—Type K is heavier. You use Type L most often aboveground, as both water and gas piping, while you use Type K almost exclusively for underground water piping. Type K soft copper is also used to run water service lines between public mains and private homes.

You can join rigid copper with soldered—or sweat—fittings, compression fittings, and push-fit fittings. You can join soft copper with compression and flare fittings. Threaded adapters are available for joining copper to any other threaded material, including threaded steel and CPVC plastic. Only soldered and threaded fittings can be hidden in walls, however.

Cutting Water Pipes

The methods and equipment you need to cut water pipes depend on the piping material itself. Many people cut copper and galvanized steel with a hacksaw, but a tubing cutter leaves a more uniform edge. You can also cut plastic pipe with a tubing cutter, but most do-it-yourselfers reach for a hacksaw instead. The reason has less to do with the quality of the cut than with the availability of the tool. Tubing shears are probably the best cutting tool for plastic.

A clean, straight cut is also important. A tubing cutter can leave a compression ridge inside the pipe, while hacksaws leave coarse burrs. Ragged burrs protruding from a pipe’s edge will eventually break off and make their way into control valves, appliances, and faucets. Severe edges also create friction in the water flow, called line friction, which can reduce pressure. And finally, raised edges generate turbulence, which can eventually erode the pipe wall. To prevent these problems, ream any severe edges left by a cutting tool before you install the pipe.

To ream a copper or plastic pipe, lift the triangular reaming attachment from the top of the cutter, insert it into the end of the pipe, and give it several sharp twists. When dealing with steel pipe, you’ll need a more aggressive reaming tool—one with hardened-steel cutting blades. You can rent many of these tools. If you are making only a few cuts, use a rat-tail f...