- 288 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Designing Innovations in Industrial Logistics Modelling describes practical methods for approaching the task of designing industrial logistics systems. It surveys the development of logistics models and their application in manufacturing to designing, planning, and implementing the movement of supplies, equipment, and products.

This text/reference book discusses the combination of operation and production research to obtain solutions for designing and integrating advanced logistics systems. It provides the reader with a set of prescriptive and descriptive models and methods that have been developed exclusively for the purpose of designing, managing, and optimizing the architecture of such advanced systems.

The design and application of new tools and methods is presented in such a way that emphasizes the competitiveness of manufacturing industries, and case studies are presented in a manner that demonstrates successful models and methods in advanced industrial logistics systems. In addition, Designing Innovations in Industrial Logistics Modelling explains the various formal tools and methodologies employed in evaluating new programs and covers program management and dynamic evaluation techniques.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Designing Innovations in Industrial Logistics Modelling by A. Kusiak,M. Bielli in PDF and/or ePUB format, as well as other popular books in Matemáticas & Matemática aplicada. We have over one million books available in our catalogue for you to explore.

Information

PART 1

PROBLEMS AND TRENDS IN THE DESIGN OF INNOVATION PROGRAMS IN LOGISTICS

Chapter 1

RESEARCH PERSPECTIVES IN INDUSTRIAL LOGISTICS DESIGN

Dipartimento di Sistemi di Produzione ed Economia dell’ Azienda - Politecnico di Torino, Italy

Istitnto di Analisi dei Sistemi ed Infonnatica Consiglio Nazionale Ricerche, Roma, Italy

1. INTRODUCTION

The possibility of utilizing a good logistic system in an industrial plant appears to be a key factor for the successful implementation and management of a flexible manufacturing plant. Owing to the crucial importance of flexibility when turbulent market demands have to be satisfied, high capability of the logistic system to servicing “just in time” the requests for tools and components of the machining centers is an absolute need.

Often in the past the design of an Industrial Logistic System (ILS) has been considered a secondary task to be solved once the arrangement of the machining centers and of the storage places in the department space has been completed. Recently, industrial managers have realized that the amplitude of demand variabilities directly reflects into a wider product mix and then into higher requests for tool and part movements [1,2], thus making the ILS design a crucial task for assuring a successful manufacturing process.

Attempts made for reducing the time spent at machining centers in waiting for tools and components are showing that the problem of obtaining a “good” ILS cannot be solved at all by only designing a good network of connections among machining centers but it also requires defining a sound strategy for managing movements of parts and tools in time [3]. Moreover it has been recognized in practice (and it appears to be quite obvious also from a theoretical viewpoint) that only a combined optimized design of the ILS structure (i.e., layout) and of a specific ILS management strategy can assure the industrial end user an Efficient-Effective-Economic (E3) logistic service [4].

From both practical and theoretical points of view, the joint design of an ILS layout and the related ILS management system appears to be a very complex task involving several design subproblems:

(A) ILS layout design subproblems, i.e.

• drafting the ILS network of connections;

• planning the average production flows;

• planning the buffers sizes;

(B) ILS management design subproblems, i.e.

• designing a master scheduling strategy;

• designing a distributed service and dispatching control strategy.

The above outlined decomposition has been mainly originated by practitioners and managers operating in industrial shop-floors: as a consequence, it suffers the intrinsic weakness of heuristic approaches.

Now theoreticians are requested to formulate prescriptive models of the complete set of design subproblems and of their interrelations (we call this set an organization of design subproblems) in such a way that the individual design strategies (obtained by solving each subproblem individually) as well as the convergence of all the organization of said design strategies can be justified.

The goal of this chapter is to outline a new formulation of the mentioned organization of design subproblems and to focuse on the most crucial subproblems which industrial managers need to solve by applying robust and guaranteed solution procedures.

Main lines of the chapter are as follows.

In principle, an organization of design subproblems can be modeled as a table of relations among the subproblems themselves such that each entry of the table contains a model of the data and constraints which one subproblem induces on another one. A similar table describes relations among the solution strategies of the above mentioned subproblems, showing for each strategy the design resources required for its implementation.

This concept of subproblems/strategies tables focuses on two main industrial tasks to be tackled in the ILS design, namely:

• managing the resources required for developing and implementing an organization of design strategies;

• developing effective design strategies for the most critical individual subproblems.

When considering each one of the two tasks in an industrial frame, a proper line of evolution can be recognized. The former evolves towards utilization of Concurrent Engineering tools [5]. The latter shows a growing interest of manufacturing plant managers in modular organization of the manufacturing plant [6].

Which may be the most significant motivations of these evolution lines?

This chapter tries to propose answers and suggests research perspectives.

2. ILS DESIGN: LOGICAL STATEMENT

In dealing with the ILS design task, industrial managers’ requirements imply that two main problems have to be approached:

(A) given a set of requirements specifying the expected service target and a technological data base including information on the available ILS components, it’s required to design the ILS layout by detailing the connections, routes, and storage places, as well as the types of devices to be used for moving and storing parts and tools in the manufacturing department;

(B) assumed to have at disposal an ILS layout and given specific scenarios for the parts and tools supply demands, it’s required to design the ILS management strategy by detailing how parts and tools have to be addressed on alternative routes and stored in available buffers in such a way to avoid blocking and starving situations at machining centers and assuring their maximum possible utilization for given release time and due date constraints.

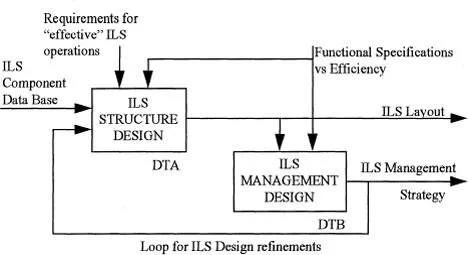

The two problems are strictly connected together because the design of an ILS layout cannot be completed and validated except in the case of an ILS management strategy that has been adapted on the selected layout. On the other hand, an ILS management strategy cannot be effectively optimized except in cases where an appropriate ILS layout could be adapted to the demands scenario (Figure 1).

This second consideration appears to be particularly true when a net-based ILS layout has to be designed and optimally managed for a wide variety of parts and tools to be moved and fast variations of the part/tool demands.

According to a more detailed view, the ILS layout design can be organized into three steps:

(A-1) organization of the network of connections, that means definition of the graph of admissible connections among the machining centers and their services (as tool room, buffers and QC/measurement services), based on the technological constraints specified by the process plans to be implemented;

(A-2) preliminary evaluation of the average loading conditions for the desired ILS, assuming a given scenario of the part/tool demands, and using the simplest possible model of the part/tool movements in the manufacturing department, and consequent planning of the ILS storage and transportation capacities in such a way to assure that the service requirements could be satisfied with the maximum possible efficiency;

(A-3) organization of the ILS layout by verifying the consistency between the storage and transport capacities required and the capabilities of available technologies and components; more precisely ILS layout organization implies:

• verification of the opportunity of utilizing all possible locations and types of storages proposed in step (A-1);

• evaluation of the convenience of utilizing different devices on same links for transporting different items (e.g. parts and tools), and then synchronization of the supplies of the required items at each machining node;

• or, on the contrary, evaluation of the convenience of utilizing same devices on the same links;

• comparison...

Table of contents

- Cover

- Title Page

- Copyright Page

- Preface

- Table of Contents

- Part 1 - Problems and trends in the design of innovation programs in logistics

- Part 2 - Models and tools for designing innovations in logistics

- Part 3 - Case studies

- Part 4 - Information technologies for managing and promoting innovations in logistics

- Index