eBook - ePub

The Lean 3P Advantage

A Practitioner's Guide to the Production Preparation Process

- 336 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

How do you take talented engineers and surround them with the elements needed to create brilliant designs that lead to market-changing products? Lean 3P is how.Winner of a 2013 Shingo Research and Professional Publication Award !Written from an operations perspective, The Lean 3P Advantage: A Practitioner's Guide to the Production Preparation Proce

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access The Lean 3P Advantage by Allan R. Coletta in PDF and/or ePUB format, as well as other popular books in Business & Operations. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Lean 3P Design Concepts

What Is 3P?

Lean 3P is an integral element in Lean Product Development; however, it is not a holistic Lean Product Development process in and of itself. Depending on how it is applied, it can expand or contract to meet the needs of the organization either receiving input from other Lean Product Development elements or pushing outward into them.

If Lean can be defined as the engagement of people in the act of continually increasing value creation in our processes, then Lean Product Development must focus on that goal as related to the myriad of processes that take place as clever ideas are translated into successful products in the hands of happy customers. The focus of product development is largely about learning and then applying that knowledge to the targeted application. Market analysis, voice-of-the-customer, technology development, and even project planning and management are critical elements of product development and like all processes, they can be improved by applying Lean thinking.

Lean 3P should be inserted early in the Product Development process, as we’ll explain later, and will be used to align all of the many vertical functions in our horizontal value stream, in order to optimize the new product concurrently with the operation that will produce it, in consideration of the people who will interact with it. Readers interested in a broader look at the full Lean Product Development process are encouraged to read Lean Product and Process Development (Ward 2009), or Mastering Lean Product Development (Mascitelli 2011).

The output of the product development process provides the recipe that sets the stage for a profitable value delivery system, which satisfies the needs of the targeted customer. The 3P (Production Preparation Process) process provides a collaborative and concurrent framework to link the product and process design. Most companies utilize new product development processes that treat product design and process design as independent and discrete entities. Integration of the two improves both and reduces the time and costs required to bring the product to market. Lean 3P is event-based team activity that employs a broad range of stakeholders from many different functional areas, including product design, process design, operations, procurement, and representatives from other internal groups. It could also include customers, suppliers, and outside experts.

If the product is in the early conceptual design stage, the 3P event will focus on understanding customer wants and will work to create numerous prototype models depicting different features that satisfy those wants and needs in different ways, using a rapid, iterative process to get feedback and direction. With every prototype, manufacturability is considered. As the product becomes more defined the balance shifts to design of the process, developing many alternatives for each functional step of the process. Changes to the product, including packaging, are considered as manufacturing alternatives and are evaluated before collapsing down to the better alternatives. Physical prototypes are created for the best alternatives, and every feature of the proposed new process is evaluated and compared. The tension between product design and process design continues throughout the event, and both are refined as the design concepts are tested, improved, and retested over and over again.

3P is a Lean design process that provides opportunity to achieve the lowest overall product life-cycle cost because it encourages innovation and collaboration with all of the key stakeholders very early in product development, utilizing all of the tools in the Lean toolkit. This in itself is atypical because Lean tends to be the approach we take to solve problems, not prevent them. Most of our Lean experience involves Kaizen efforts aimed at improving existing processes. In a very real sense, Lean 3P is no different. We are simply applying the same methodology to the design process. Perhaps the real difference is that we are applying the Kaizen discipline methodology to two processes, product design and process design, concurrently. By avoiding problems and pitfalls very early in the product development process, costs can be minimized, quality can be designed in, and many future headaches are avoided.

This is not intended to imply that new product and process development is simple. The fact is that both aspects of design are very complex and fraught with pitfalls. The people part of the equation is a third dimension that is often overlooked or discounted. The people element includes understanding what will really delight a customer. It also considers other groups who will interact with the product or operation. This includes people like the maintenance person who will be charged with keeping the new line going, and the operator, ensuring that he or she will be fully engaged in value-adding work while running the operation, and many more.

Caution: Lean 3P proactively employs the many elements of the Lean toolkit. To be successful the team must be well versed and experienced in Lean application.

Development of the 3P process is attributed to Chichiro Nakao, a former Toyota group manager and the founder of Shingijutsu Company, a Japanese consulting firm. The accepted meaning of 3P is Production Preparation Process. As more and more companies have begun to use 3P this definition seems to have become established. 3P allows a group of people to codevelop a product and the operation that will manufacture it in a way that adds value to both aspects—essentially a robust, well-thought-out production, preparation process.

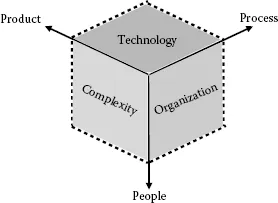

3P is sometimes referred to as Product, Process, People, and this definition probably captures best the spirit of 3P. It focuses and attempts to optimize the collective design of the actual product and the production operation that will produce the product, with strong input from and consideration of the people who will interface with it from all the many different functional areas. Figure 1.1 represents the balance between product, process, and people that Lean 3P endeavors to attain.

The Product reference defines the necessary product attributes via analysis with deep understanding of the true functions and features that the customer desires, in conjunction with the impact on its overall manufacturability. We tend to think largely of functional benefits when considering a product, but the way it is packaged, displayed, and labeled can influence customer acceptance, and profitability. Developing a product this way could sound limiting and restrictive, but the process of collaboration and incorporation of other viewpoints should only make for a better product and a more profitable one.

Process looks at the means of physically moving materials, interactions of people, and producing product in a commercial operation by first developing a full understanding of the actual value-adding features and then considering manufacturing alternatives that best meet those criteria. When Product Development and Operations people achieve a common understanding of the important product features in the context of how that product is made, together they can make intelligent decisions that satisfy both needs without sacrificing functionality or increasing costs. 3P intentionally develops the process with input from hourly workers who will operate and interact with it, gaining a unique and valuable perspective that is normally ignored.

Figure 1.1 The three dimensions of Lean 3P.

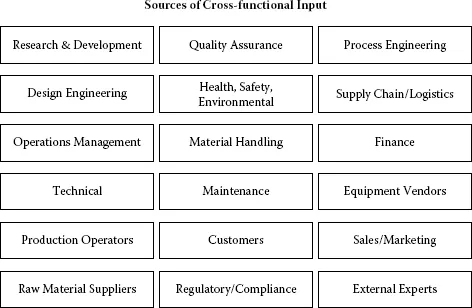

The People aspect of 3P considers customer needs, process work flow, accessibility for operator interaction and maintenance, workplace organization (5S), lighting, work heights, changeover processes, as well as material handling, set-up of local material storage (supermarkets) and replenishment systems (Kanban), and a host of other elements that are very easy to consider up front but are often difficult to impossible to incorporate later. The people aspect often has a significant benefit to ongoing costs of operation, but it goes far beyond just operators, mechanics, and material handlers. 3P can utilize all of the stakeholders whose functions touch the product or process, and each one can leave his or her mark on the improved process, baked-in from the beginning. Figure 1.2 shows the possible participants in the Lean 3P process.

Lean 2P

Very often a product has already been defined and is being sold commercially and additional capacity is required because demand is growing. Product changes then become much more difficult and sometimes impossible because of the risk any change could pose on customer perception or established features. We find ourselves in a position where we need to expand production operations but cannot greatly influence the fit, form, or function of the product. What do we do when limited in this manner and not permitted to touch the product’s look, feel, or design? Fortunately Lean 3P design still works, though some optimization will be limited. The ability to use a multidisciplined approach to collaborate on the design of a new process can still yield enormous benefits. When product development and change are very limited, the process is referred to as 2P (Production Preparation).

Figure 1.2 Direct and indirect contributors to a typical product value stream.

The first exposure I had to 3P was primarily a Production Preparation exercise. It was an existing operation that had started out as a development prototype and continued to be used successfully to manufacture commercial product. As the product demand grew over the years new bits of kit were bolted on and added to increase capacity. The control technology employed was becoming increasingly difficult to maintain and we recognized a significant risk of failure. In addition, sales demand continued to grow and was threatening to exceed our production capacity within 2 years. We applied 2P by forming a very diverse, cross-functional team inclusive of Operations, Planning, Procurement, Process Engineering, and other groups, including some of the original senior scientists who developed the product. It was the latter group that proved the most interesting. We will discuss the 3P process in detail later, but suffice it to say that these brilliant people absolutely flourished at the point in the process when people are encouraged to think as they did when they were 12 years old. It was almost as if they had never stopped thinking that way. The other interesting observation was that “tribal knowledge,” the combination of biases and beliefs that we passionately adhere to, irrespective of the science or facts behind them, was just as much a part of the senior scientist’s mindset as it was the operator who ran the line. During the event, everyone’s ideas were challenged. Everyone learned. When it was done a highly collaborative team had bonded together, and together they developed an amazing production operation.

The application of 2P, where a new process is being developed with limited ability to change the product, is actually much more prevalent than 3P. It should be considered whenever additional capacity is needed to satisfy demand or reduce costs. It also applies when a variation of an existing product is added that requires an operational overhaul. In companies new to Lean 3P the leap to concurrent development of both product and process might seem insurmountable. Applying 3P to the development of a new operation may allow introduction of the concepts in a more confined manner, enabling it to eventually expand upstream to the product design processes as the benefits become more apparent to the organization.

Throughout the book we refer to the process as 3P. The truth is that in every event, there is an opportunity to challenge the fit, form, and function of the product and its packaging. With even the most established products, good ideas for improvement will generally be entertained, and considered if they create enough value. Some of the changes might need to be placed on a back-burner to be researched and applied at a later date, but do not assume that product improvements are completely “off the table” even when you are told so. As someone once said, “No is simply the starting point of the negotiation,” and any 6-year-old child would agree.

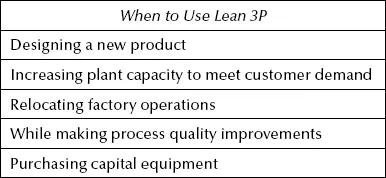

As a rule of thumb, Lean 3P can be used whenever you are designing a new product, making significant changes to existing product features, increasing plant capacity to meet growing customer demand, relocating factory operations, making process improvements to improve product quality rates, or planning capital equipment purchases. As we explore later, the key elements of Lean 3P can also be applied to more modest design changes in a way that adds similar value on a proportionally smaller scale. Figure 1.3 explains when to use Lean 3P.

Figure 1.3 Events that benefit from Lean 3P.

Why Does 3P Work?

The 3P process sets the stage for engineers to collaborate and share dialogue with a broad cross section of stakeholders before too many decisions have been committed. The term collaboration invokes the idea that stakeholders from the functions somehow gain a revelation and everyone sees the world in the same way. Nothing could be farther from the truth. In Lean 3P the functional representatives are there to ensure that their needs are met. Collaboration develops as the tension between the different functions is resolved after evidence-based debate. During every new product design and new process design we are in a learning mode. We are attempting to gain enough knowledge to move the process in the right direction as it lumbers down the path toward product launch. 3P provides a structure that promotes low-cost experimentation that rapidly increases our understanding of product and process and creates a higher probability of launching products more successfully.

As we consider the creation of value within any product value stream it is quickly recognized that customer value is only created as the product flows horizontally across the value stream. In his book Gemba Walks (Womack 2011) Jim Womack points out that while customer value is generated horizontally, businesses are organized vertically, with functional silos that tend to sub-optimize, often at the expense of upstream and downstream functions. Lean 3P seeks to include these functions in a way that allows consideration of functional needs while always maintaining a focus on true customer value.

Separating R from D

What would product development look like if we separated research from development? Research is where invention takes place and where limitations and restrictions are given a back seat to allow brilliant new ideas and concepts to be pursued. Development’s role is to take those discoveries, develop a thorough understanding of their attributes, and transform them into a product that creates customer value and delivers profits.

Research and invention is a topic that conjures up images of da Vinci and Edison and other giants of science and technology, and there are many proposed methods aimed at capturing its essence. The debate between individual genius and collaboration continues to wage with no clear winners. When invention is applied with a clear focus on development of new products the field narrows, but there are still many different schools of thought regarding which process renders the best results.

When we think about the creation of a new product, where does the idea actually come from? Who really develops it? Who are the people who influence what a product will achieve both functionally and aesthetically? Is it the customer or a marketing team? Perhaps it is a sales person who thinks he understands his customer’s needs or maybe it evolves out of a corporate think tank somewhere. Possibly it is discovered by accident in a research laboratory as happened with Spenser Silver’s discovery of the glue for Post-it® Notes. Maybe it takes the form of biomimicry as in the case of George de Mestral’s discovery of Velcro, found after closely examining the burdock seed’s tiny “hooks” under a microscope.

However a potential solution to a defined need is identified, when it occurs, the concept for a new product is born. After that discovery another flood of questions arise and vast amounts of new information are required. How much will a customer be willing to pay for this product? What features will a customer value? What elements are simply required and which new features would add value that could differentiate it from the competition?

The...

Table of contents

- Cover

- Title Page

- Copyright Page

- Dedication

- Contents

- Preface

- Acknowledgments

- Introduction

- 1 Lean 3P Design Concepts

- 2 Lean 3P’s Place in the Product Development Process

- 3 Applying Lean 3P Design and Gaining Leverage

- 4 Getting Started

- 5 The Countdown and Overview of the 3P Event Week

- 6 Kickoff, Charter, and 3P Goals

- 7 Product Planning and Process Evaluation Criteria

- 8 Defining Value-Adding Functions

- 9 Flow Diagrams, Developing Seven Alternatives, and Selection of the Better Three Alternatives

- 10 Process at a Glance, Selecting Teams, Constructing the Three Prototypes

- 11 Rapid Evaluation of the Three Prototypes, Selecting the Final Prototype

- 12 Developing the Final Prototype, Incorporating Evaluation Criteria, and Measuring Effectiveness: Final Report-Out

- 13 3P Project Management: Potholes and Stumbling Blocks

- 14 Evergreen Lean 3P Design: Conclusions

- Appendix

- Index

- The Author