- 360 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Practical Guide to Pressure Vessel Manufacturing

About this book

This text explains vessel manufacture and procedures for quality assurance and control, methods for code specification compliance, all stages of the manufacturing process, and promotes uniformity of inspection, testing, and documentation. Analyzing radiographic testing procedures, the book acts as an explanation to the ASME code, features the A to Z of fabrication methodology, discusses NDT, heat treatment, and pad air and hydrostatic tests, methodology to compile a Manufacturer's Data Report, typical quality, inspection, and test plans, the requirements of welding procedure specification, procedure qualification records, and welder qualification tests, and recommended tolerances for vessels.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Practical Guide to Pressure Vessel Manufacturing by Sunil Kumar Pullarcot in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Energy. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction

1 GENERAL

Pressure vessels are manufactured all over the world under various international standards. These standards do specify the requirements to be met during the manufacture of pressure vessels; however, the means used to meet these requirements are not specified in any of these standards. In the following chapters, a detailed methodology to check each essential parameter specified in the relevant standards is established. Even though the attempt is made based on ASME Section VIII Div (1), the same methodology could also be extended to pressure vessels manufactured under different standards. The only difference would be in the acceptability norms that obviously could be gathered from the applicable standard.

2 PRESSURE VESSEL

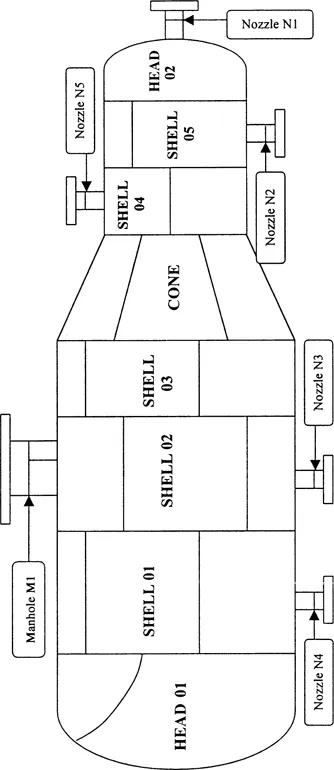

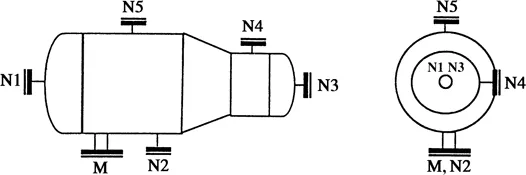

A vessel used for the containment of pressure (either internal or external) is a pressure vessel. Pressure vessels can be of any shape. However, the most complicated one, as envisaged in ASME Section VIII Div (1), is shown in Figure 1.1.

3 STANDARDS

The most commonly used standard in the manufacture of pressure vessels in India is ASME Section VIII Div (1) even though there is another Indian standard for unfired pressure vessels. The standards that are commonly used in India for the manufacture of pressure vessels are the following.

- ASME Section VIII Div (1): Rules for Construction of Unfired Pressure Vessels

- ASME Section VIII Div (2): Alternative Rules for Construction of Unfired Pressure Vessels

- ASME Section VIII Div (3): Alternative Rules for Construction of High Pressure Vessels

- IS 2825: Indian Standard code for Unfired Pressure Vessels

- BS 5500: Specification for Unfired Fusion Welded Pressure Vessels

- Chapter J of Rules and Regulations for the Construction and Classification of Steel Ships by Lloyds Register of Shipping

- AD Merkblater Technical Rules for Pressure Vessels

4 METHODOLOGY

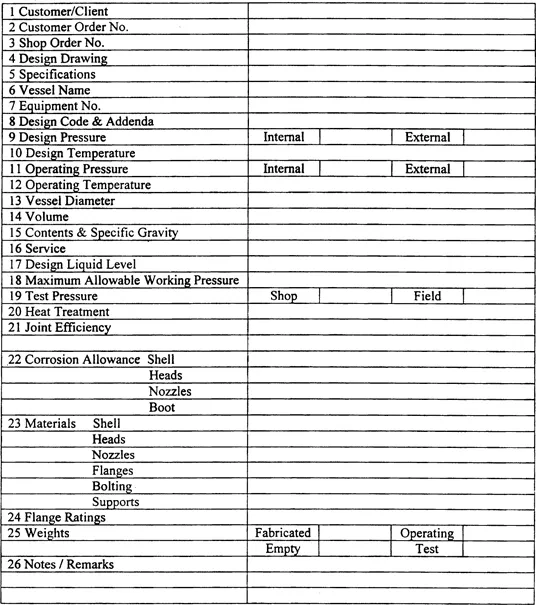

The basic information for designing pressure vessels, being a part of the process plant, should be formulated by the process engineering group and contain such criteria as shown in Figure 1.2. This is known as the design data sheet (DDS).

Additional conditions that are to be considered during design, manufacture, and testing, along with technical/commercial conditions of delivery, will be furnished in a document called the technical procurement specifications (TPS), which is part of the purchase order (PO).

Based on the design data sheet and other technical conditions, the design department of the fabricator performs the design calculations as per the applicable code, and a detailed fabrication drawing is prepared. This in turn is sent to the client, consultant, third party inspection agency, statutory authority, etc., for their scrutiny and approval.

After the approval of the design and drawings by various agencies (primarily the client or consultant), the planning department of the fabricator generates material requisitions to the procurement department. The material requisition is just a translation of all the relevant data given in the drawing as well as in the TPS in a form that can be understood by the vendor for that particular item.

The purchase department floats enquiry for materials to reputed vendors who are already registered with the fabricator. The department is primarily responsible for obtaining materials of required quality at the lowest price and within the stipulated time frame. The responsibility of the department ceases only when the material is received at stores and accepted by the quality assurance and control (QAC) department.

On receipt of the material, the planning department issues a work order to the production department with authorization to draw materials from stores along with certified-for-fabrication drawings and a detailed delivery schedule for the work.

The production department in turn works out its microlevel planning based on availability of manpower and machines to meet the deadlines committed to the client.

The microlevel planning of the QAC department is carried out in such a way that it shall not conflict with the overall production schedule nor the microplanning of production.

With the concerted efforts of all the mentioned departments, as well as the other service departments like stores, maintenance, personnel, finance, etc., the targets for cost, time, and quality can be met. If these targets are achieved, it paves way for prosperity of the organization.

2

Organization

1 THE NEED AND ROLE OF ORGANIZATION

In order to achieve the required level of quality in production, all the departments mentioned in Chapter 1 must function in a concerted and organized manner with the ultimate aim of better and consistent overall quality for the product. This in turn calls for a strong and well-defined organization well interlaced between departments so that all departments function as a team with a single corporate objective, rather than focus on the best performance of any individual department. The product quality shall in no case be lower than that desired by the client in the specifications. At the same time it need not be of extremely high quality, in which case the product cost would also be very high. The organization shall be capable of delivering the products of optimal quality at the lowest cost. Therefore, repairs and reworks shall be avoided to the extent possible as they inevitably turn out to be very expensive in terms of both money and time. With this objective in mind, this chapter describes a successful organizational model based on the author’s experience in the field.

2 ORGANIZATION CHART

A typical organization chart for a medium scale pressure vessel manufacturing setup is shown in Figure 2.1.

The positions shown in the organization chart can be broadly classified into three levels. The level consis...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Preface

- Contents

- Part I Fabrication

- Part II Procedures

- Index