Processed Fishery Products

Maria João Fraqueza1, *, Manuel Abreu Dias2 1 CIISA/Faculdade de Medicina Veterinária, Universidade de Lisboa, Avenida da Universidade Técnica, 1300-477 Lisboa, Portugal

2 Alicontrol, Tecnologia e Controlo de Alimentos, Lda., Rua Fernando Vaz, lote 26-B, 1750 108 Lisbon, Portugal

Abstract

Many fish preservation technologies are based on multiple hurdles used to inhibit or reduce biochemical changes and microbial contamination that leads to spoilage. This chapter aims to describe some of the most traditional technologies currently applied to fishery products based on the control of water activity, pH, oxide-reduction potential, temperature, relative humidity and gaseous composition of the atmosphere. Emergent technologies, such as Ohmic heating and microwaving; amongst others, can be seen with particular interest for future application at industrial scale. In fact, the combination of traditional and emergent technologies (thermal or non-thermal processes) in processed fishery products, might be the trend to achieve and supply safer and high quality products.

Keywords: Chemical treatments, Emergent technologies, Non-thermal treatments, Processed fishery products, Thermal treatments.

* Address correspondence to Maria João Fraqueza: Faculdade de Medicina Veterinária, Universidade de Lisboa, 1300-477 Lisboa, Portugal; E-mail: [email protected] INTRODUCTION

A major purpose of the processed fish production is to preserve fish, minimising losses in the distribution chain, over time and space. Another important goal for that industry is to add value to raw fish materials, which might be related to the application of emergent technologies, in order to develop new fishery products. Nowadays, there is an increased demand of ready-to-eat food products, or those

requiring little or no preparation before serving. So, the further industrial processing of fish is not only common, but also desirable, to sustain the demand for a wide variety of value-added products. Fishery products processing industry receives raw fish materials (sardines, tuna, cod, mackerel, anchovy, crustaceans, molluscs) directly from fishery and preserves them using traditional preservation technologies. Presently, these technologies are more mechanized and automated in some processing steps. Processed fishery products include preparations, canned, chilled, frozen, smoked and dried fish, crustaceans and molluscs. The technologies for fish preservation aim the inhibition or reduction of the metabolic and biochemical changes that lead to spoilage. These preservation technologies are based on the control of specific parameters such as water activity, pH, oxide-reduction potential, temperature, relative humidity and gaseous composition of the atmosphere surrounding food under packaging. In general, technological treatments are physical (thermal treatments: cooling, freezing, pasteurization, sterilization, Ohmic heating, microwaving, and non-thermal treatments: irradiation, high hydrostatic pressure, ultrafiltration, pulsating electric fields, ultrasound and even dehydration) or chemical (addition of sugar, salt, acids, additives), the last with repercussion on the chemical composition of foods. Some of these technologies are currently applied to fishery products processes (pasteurization, sterilization, dehydration, addition of sugar, salt, acids, additives), others have been tested but without large industrial application (irradiation) while emergent technologies, such as Ohmic heating, microwaving, high hydrostatic pressure, pulsating electric fields, may be seen with particular interest by industry. Many fish preservation technologies are based on Leistner’s [1] multiple hurdle theory, such as pasteurization-refrigeration, cook-chill, modified atmosphere packaging - refrigeration, salting-drying, salting-smoking, drying-smoking and salting-marinating .

All these technological processes may be applied to raw fish material aiming to have the best quality; however, it is mandatory to assure food safety. With that purpose, not only unitary preservation technologies should be applied but also safety measures founded on proactive methodologies such as Hazard Analysis Critical Control Point (HACCP) method. Finally, proper waste structures should be included in fish processing operations.

PRELIMINARY PROCESSING FISH OPERATIONS

The type of raw fish material affects its processing, being relevant to distinguish demersal fish (codfish, flatfish), pelagic fish, crustaceans (shrimp, prawn, lobster) and molluscs. Preliminary processing should assure the best market quality and safety of fish products, a suitable presentation of semi- processed final product, labor saving on raw materials processing, and waste reduction. Considering different fish, crustaceans and molluscs raw materials, with different specificities that enter a processing unit and all the obtained final products, proactive methodologies need to be implemented for hazards prevention and for decreasing human health and environmental risks.

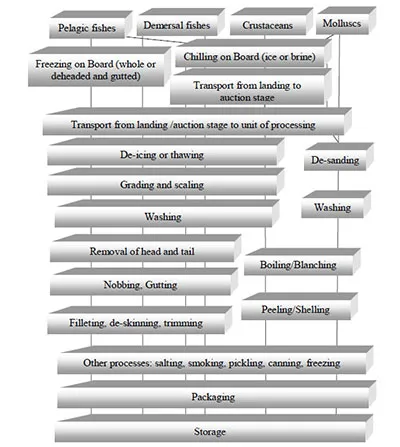

Concepts related to HACCP methodologies and “cleaner production” must not be forgotten. The application of a proactive methodology, such as HACCP, involves a precise methodology of preventive measures to be managed throughout the fish products processing steps, according to an established plan which is a document for identifying, evaluating and controlling food safety hazards [2]. “Cleaner production” is a concept that seeks efficiency improvement and reduction of risks to humans and environment by the applying precautionary ecological approaches to practices, produces and services. It intends the preservation of fresh resources and energy, removal of toxic constituents, and decrease in quantity and toxicity of litters and discharges [3]. Typically, a fish processing industry spends considerable amounts of energy and water, and releases substantial amounts of biological effluents and solid wastes. Also, because of all the hand labor and manual operations, the fish industry is dependent on the operator performance, which in turn influences plant performance, mainly in small-scale units and low automated automat operations. The main steps of fish preliminary processing can be illustrated in a diagram as shown in Fig. (1). Fish is a perishable raw material, and immediately after death must be beheaded, gutted, washed and chilled to prevent enzymatic degradation and spoilage by microorganisms. Main fish preliminary processing operations are common to different methods of preservation beginning by sorting, grading, washing, flaking, head and tail removal, gutting, de-skinning, filleting, and trimming.

Fig. (1)) Preliminary operations in fish processing industry.

Demersal fish processing is usually quite straightforward, but pelagic fish involves further processing for the production of more elaborated foods, including pickled herring and canned mackerel and sardine. Crustaceans and bivalve molluscs can be transformed into several products, being usually boiled. Fish transport inside an industry should be seen as a fundamental operation that contributes to a cleaner production. Dry transport is a better solution to avoid large quantities of water waste and to reduce the content of organic material in wastewater, with a high benefit for the environment [4], but it damages fish more than water transportation. This kind of transport is able to move and position fish in the machinery by the use of specific filter conveyer belts and brushes [4].

Sorting and grading can be done by specie and size, either manually or mechanized. Roller, vibration and belt graders are commercially available depending on the fish products to be graded. Small or large pelagic, demersal fish and crustaceans are usually sorted by grading machines. Fish grader is designed and built for high capacity grading of fish into several size categories according to species, ranging from sardines, herring and mackerel to large cod, salmon and tuna. The machines segregate the fish into different grades using as example rollers tracks (Fig. 2).

Fig. (2)) Roller grader machine performing fish grading (courtesy of Timars manufactor).

The fish fall into the containers or belts positioned below, from where they are separated into storage boxes or transferred to other conveyors for further processing. These equipment’s might include water sprays that wash the fish at the same time as it passes down the tracks. In order to clean fish and diminish bacterial contamination, washing is usually performed with potable water in a minimum proportion 1:1 water and fish [5]. The optimal washing is reinforced by the mechanical friction of a rotating drum (with vertical or horizontal axis), depending on rotational speed, fish washer height and angle, angle of water supply and vane angle. This operation step may be performed when the fish enters...