eBook - ePub

Flame Spray Drying

Equipment, Mechanism, and Perspectives

- 142 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Drying processes are among the most energy-consuming operations in industry. Flame spray drying (FSD) is a novel approach to reduce the energy supply needed for the spray drying process. Flame Spray Drying: Equipment, Mechanism, and Perspectives describes FSD technology and current developments in flame techniques and evaluates potential industrial implementation.

-

- Details advantages of FSD in terms of energy consumption and reduced drying time

-

- Promotes applications of biofuels for the drying process

-

- Analyzes the FSD method from CFD modelling to product quality

-

- Evaluates potential safety and product degradation risks

-

- Provides examples of potential applications of the FSD technique in drying of different materials

This book describes an important new technique that is useful to chemical and process engineering researchers, professionals, and students working with drying technologies.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Flame Spray Drying by Mariia Sobulska,Ireneusz Zbicinski in PDF and/or ePUB format, as well as other popular books in Ciencias físicas & Ingeniería química y bioquímica. We have over one million books available in our catalogue for you to explore.

Information

1 Principles and Mechanism of Flame Spray Drying

DOI: 10.1201/9781003100386-1

1.1 Principles of Flame Spray Drying Process

Drying as one the most energy-consuming operation is responsible for about 10%–25% of energy consumption in the industrial sector (Law and Mujumdar 2010). Spray drying is a widely applied technique for dewatering of the liquid feedstock such as solutions, slurries, emulsions, and pastes into powder product. Due to low thermal efficiency (Filková, Huang, and Mujumdar 2014), spray drying process consumes large amounts of energy (4,500–11,500 kJ/kg H2O) compared with other drying methods such as tunnel dryers (5,500–6,000 kJ/kg H2O) or fluid bed dryers (4,000–6,000 kJ/kg H2O) (Zbicinski 2002).

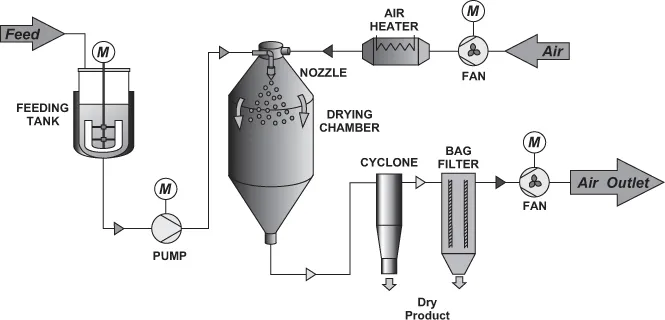

The scheme of standard spray drying (SSD) process is shown in Figure 1.1. In the standard spray dryer, the air is typically heated up in the direct or indirect heaters, and the liquid feed is dispersed into small droplets dried in the hot drying medium. In the direct heaters, the flue gases from combustion of coal, gas, or oil are mixed with air to decrease the gas temperature and supplied to the spray dryer. In the indirect heaters, the drying air is heated up by the steam, electric energy, or flue gases without contact with heating medium. Application of direct-fire heating systems with natural gas combustion increases the energy efficiency of drying process compared with steam-heated and other types of indirectly heated dryers (Strumillo, Jones, and Zylla 2006). Application of electric heating is limited only to small-scale dryers due to the high cost of electric energy, which is three times higher than that of conventional fossil fuels (Kemp 2011). The hot drying air is supplied to the spray dryer by fan, and the liquid feed is supplied by the pump to the nozzle installed inside the drying chamber. After spray drying, the dry product in the powder form is separated from the air stream in the cyclones, bad filters, or scrubbers.

According to Strumillo, Jones, and Zylla (2006), energy-saving measures, which can be applied in the convective drying processes, among others, include the following:

- Utilization of biomass or biofuels as energy sources

- Reduction of the drying time and dryer length to decrease the area of the dryer, where heat loss to the environment may occur

- Supply of the energy exactly where it is used, i.e., to the drying chamber to avoid the heat losses in the air heater

- Reduction of drying air consumption

FIGURE 1.1 Scheme of standard spray drying process.

FIGURE 1.1 Scheme of standard spray drying process. - Increase of the driving force of the process, i.e., increase of the inlet temperature of the drying medium

- Application of intermittent drying or pulsation flow of the drying medium

Generation of energy precisely in the place where it is needed, i.e., directly in the zone of moisture evaporation to avoid energy losses to the environment in the auxiliary equipment, has already been utilized in the flame drying of textiles (Remaflam® process; Eltz et al. 1985) and can also be applied in the disperse systems.

One of such an opening is flame spray drying (FSD), a novel spray drying method utilizing combustion of flammable component of the spray as an energy source for drying process, which has been developed and patented at the Faculty of Process and Environmental Engineering, Lodz University of Technology (Piatkowski and Zbicinski 2013). In the FSD process, energy required to evaporate a solvent comes from the combustion of flammable spray component, which makes drying installation independent from conventional energy sources such as gas, oil, or electricity. Moreover, FSD process gives possibility to apply different types of liquid biofuels, i.e., bioethanol or vegetable oils coming from renewable energy sources for drying process, and decrease the emission of harmful gases to the atmosphere.

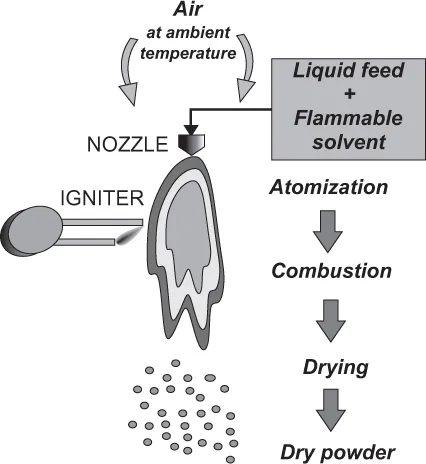

FSD consists of the following steps: mixing of flammable component with raw material, ignition, and fuel combustion, which generates heat used for moisture evaporation and particles drying (Figure 1.2). There is no air heating system in FSD process, which helps to reduce investment costs and heat losses from auxiliary equipment.

FIGURE 1.2 Principle of flame spray drying process.

1.2 Technical Requirements in Flame Drying

1.2.1 Construction Materials

The main requirement for drying chamber construction material in flame drying is resistance to high-temperature operations for a long period of time. The additional specifications for construction materials come from mechanical stresses generated by temperature fluctuations within the flame spray dryer.

The materials applied in the construction of FSD drying chambers should have the following characteristics:

- High thermal resistance (Kudra 2008)

- High mechanical strength

- High resistance to oxidation and corrosion (Romero-Jabalquinto et al. 2016)

- Low thermal expansion

- High resistance to thermal fatigue

- Low costs

- High availability

- Ease to use in manufacture process

The list of materials resistant to high temperatures with high strength and toughness commonly applied for construction of industrial furnaces and combustion chambers includes stainless steel, iron-based alloys, cobalt-based superalloys, and nickel-based superalloys (Zonfrillo, Giovannetti, and Manetti 2008). Stainless steels with high-temperature properties include both ferritic (e.g., AISI 446) and austenitic type of steel (e.g., AISI 314, AISI 310). Compared with austenitic steel, ferritic steels have lower yield strengths, whereas superalloys have the ...

Table of contents

- Cover

- Half Title

- Series Page

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Acknowledgments

- Advances in Drying Science and Technology

- Authors

- 1 Principles and Mechanism of Flame Spray Drying

- 2 Applications of Flame Spray Drying

- 3 Flame in Drying and Particle Synthesis Techniques

- 4 Safety, Energy, Environmental Issues, and Perspectives of FSD Technique Development

- Index