eBook - ePub

Downstream Processing in Biotechnology

- 177 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Downstream Processing in Biotechnology

About this book

The current book gives an excellent insight into downstream processing technology and explains how to establish a successful strategy for an efficient recovery, isolation and purification of biosynthetic products. In addition to the overview of purification steps and unit operations, the authors provide practical information on capital and operating costs related to downstream processing.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Chemical engineering methods in downstream processing in biotechnology

V. Beschkov

Institute of Chemical Engineering, Bulgarian Academy of Sciences, Acad.G.Bonchev St., Block 103, Sofia, 1113, Bulgaria

D. Yankov

Institute of Chemical Engineering, Bulgarian Academy of Sciences, Acad.G.Bonchev St., Block 103, Sofia, 1113, Bulgaria

This article has previously been published in the journal Physical Sciences Reviews. Please cite as: Beschkov, V., Yankov, D. Chemical engineering methods in downstream processing in biotechnology Physical Sciences Reviews [Online] 2021, 1. DOI: 10.1515/psr-2018-0064

Abstract

Downstream processing in industrial biotechnology is a very important part of the overall bioproduct manufacturing. Sometimes the cost for this part of biotechnologies is up to 50% of the overall expenses. It comprises product concentration, separation and purification to different extents, as requested. The usually low product concentrations, the large volumes of fermentation broth and the product sensitivity toward higher temperatures lead to specific methods, similar but not identical to the ones in traditional chemical technology.

This article summarizes briefly the unit operations in downstream processing in industrial biotechnology, making a parallel between biotechnology and chemical technology.

Keywords: biotechnology, product recovery, chemical engineering methods,

1.1 Introduction

Chemical engineering appeared in the beginning of the XXth century when the oil industry started to play important role in fuel production. Later oil had become an important source for different industrial chemical synthesis, such as plastic production, fine chemical syntheses, detergents, etc. Chemical engineering appeared to be very important for chemical technologies either, enabling the selection of more appropriate equipment and processes for better yields of high quality products.

The main processes met in chemical technologies are mass transfer in multiphase media (gas absorption, liquid/liquid and solid/liquid extraction, solid dissolution, adsorption), heat transfer (at distillation, evaporation, drying), chemical reactions in homogeneous and heterogeneous systems, catalytic conversions, etc. They can be considered separately in each particular case depending on the product properties, biomass peculiarities, etc. Another approach is the optimization of entire systems for chemical technologies accomplishment selecting the optimum process interaction in different apparatuses.

Industrial biotechnology takes the advantages and the experience of chemical technologies using similar (or exactly the same) processes and similar equipment. That is why chemical engineering science is of a great help in biotechnology design, operation and optimization. However, the operation with microbes in biotechnologies poses some differences compared to chemical technologies. The main difference between separation processes in chemical technology and biotechnology is the presence of the living cells in the mixture to be separated. Another challenge is the bioactivity of target products, which must be preserved. Sometimes the substance of interest is bound to the cell’s membrane and cells must be disrupted.

A comparison of these two types of industrial technologies is shown in Table 1.1.

Table 1.1:Comparison of chemical technologies and biotechnologies.

| Item | Chemical technologies | Biotechnologies |

|---|---|---|

| Mode of operation | Multi-step technology, many processes of intermediate isolation; batch and continuous processes | Fermentation: apparently single step final product production; batch processes mostly |

| Operating conditions | High temperatures and pressures; high-cost equipment | Ambient temperatures and pressures; low-cost equipment |

| Catalysts | Catalyst recovery required | Catalysts produced during the fermentation process |

| Reaction selectivity | Low reaction selectivity; racemic mixtures only | High hiral product selectivity |

| Operation time | Fast reactions; short time processes | Slow processes; long duration; energy consumption |

| Sterilization | No sterilization required | Sterilization required |

| Product inhibition | Variable | Strong product inhibition; low product concentrations |

As a final step, downstream processing is a very important part of industrial biotechnology following the fermentation (being the key-process) and associated with isolation of target products and their concentration and purification. According to some authors, the expenses for downstream processing may reach 50% of the total costs for certain product manufacturing [1].

Downstream processing is so important for the whole process of product formation by biotechnologies because as a rule the concentrations of the target products are usually very low.

This fact implies long, tedious and energy consuming processes which may compromise the very biotechnology.

The large-scale processes for product concentration and isolation are mostly associated with similar processes used in chemical technology: sedimentation, filtration, extraction, evaporation, distillation, drying. These processes are applied mostly for large-scale manufacturing. However, the specific properties of many biotechnological products as well as their low concentrations in the final broth need some more sophisticated approach for the product isolation, purification and recovery. That is why, new approaches for product recovery are desired.

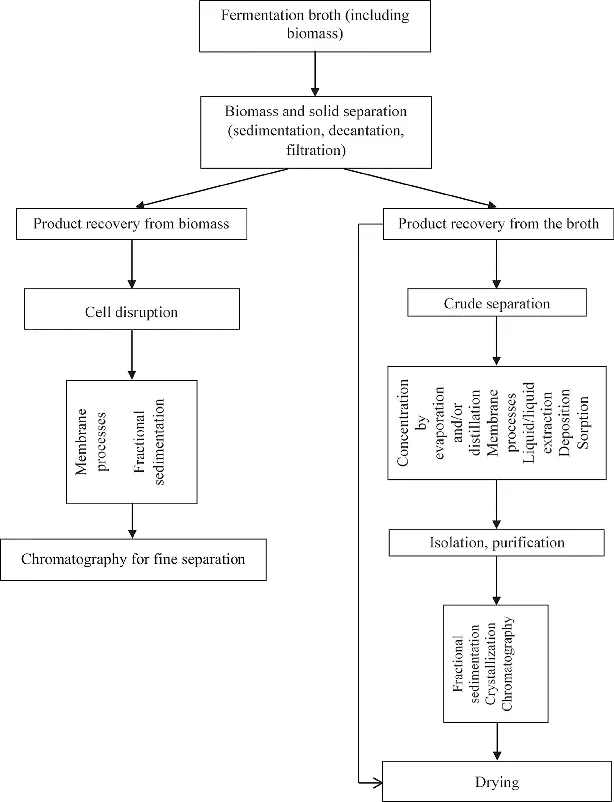

Typical bioseparation processes usually include the following steps – cell separation, product concentration, primary purification, and final purification and polishing, cf. Figure 1.1. In the case of intracellular or membrane-bound products, these steps are preceded by a cell’s disruption step. Various separation technics can be used at each step.

Figure 1.1: Principal flow sheet of downstream processing in industrial biotechnology.

Several factors must be considered when designing a bioseparation process – type and nature of the starting material, the location of the target substance, volume and concentration of the starting material, stability and bioactivity of the target product, the final physical form of the product, purity requirements, waste minimization, and total process cost.

This article proposes comparative analysis of the traditional methods of chemical technology and their improvements and alternatives for product recovery in industrial biotechnology.

1.2 Main and specific processes for product extraction and recovery in biotechnology

There are two main paths or approaches in downstream processing (cf. Figure 1.1). They are associated wi...

Table of contents

- Title Page

- Copyright

- Contents

- 1 Chemical engineering methods in downstream processing in biotechnology

- 2 Separation of bio-products by liquid–liquid extraction

- 3 Extraction and bioprocessing with supercritical fluids

- 4 Ion exchange in downstream processing in biotechnology

- 5 Electro-membrane separations in biotechnology

- 6 Aqueous two-phase systems as a tool for bioseparation – emphasis on organic acids

- 7 Ionic liquid-assisted biphasic systems for downstream processing of fermentative enzymes and organic acids

- 8 Application of polymer membranes in downstream processes

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Downstream Processing in Biotechnology by Venko N. Beschkov, Dragomir Yankov, Venko N. Beschkov,Dragomir Yankov in PDF and/or ePUB format, as well as other popular books in Biological Sciences & Biochemistry. We have over one million books available in our catalogue for you to explore.