This chapter deals with the raw material used in root cause analysis (RCA): the reports, charts, records, test results, communications, contracts, databases, and observations that are needed for an investigation. The RCA process is an opportunity to reap the benefit of consistent record keeping, process monitoring, and data analysis. The return on investment for the implementation of these good quality management system practices is having the needed resources at hand when a problem does arise so you can respond quickly and with reliable data.

This chapter will describe the sources of information and other resources utilized to determine the root cause of a nonconformance. These resources will provide the evidence to substantiate your findings.

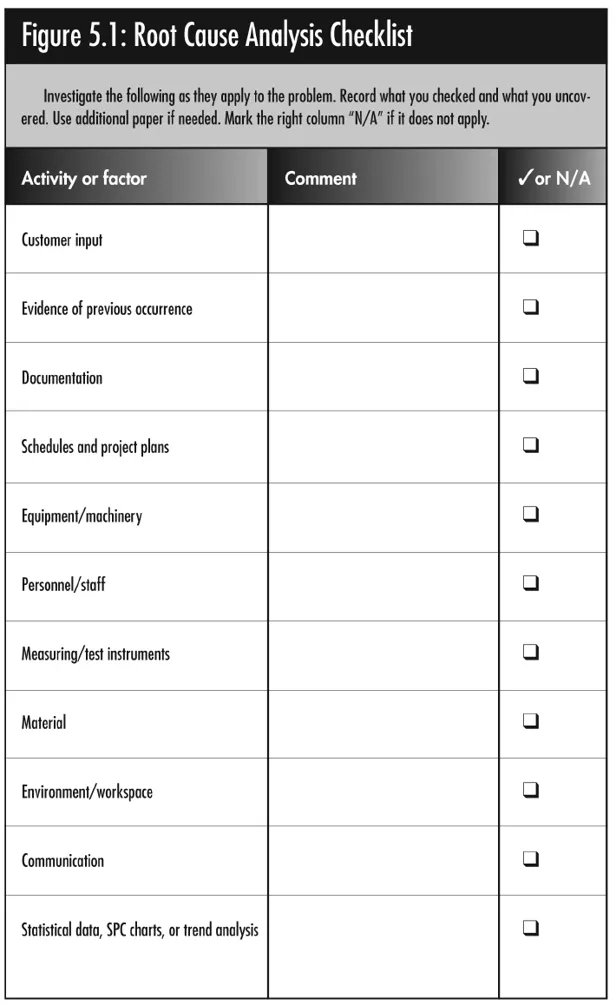

What follows is a format that facilitates the recording of the results of your investigation as it progresses. The sequence is not particularly significant. You can use the categories in any order, as long as you cover all the possible factors. Customer issues head the list because the customer should be the organization’s ultimate focus, and because so many nonconformances deal specifically with customer returns and complaints.

It’s likely that a single issue will surface in more than one category. For example, if you have the wrong revision of a customer drawing, it will likely be identified both as a documentation issue and a customer communication issue. Such a happening has the added benefit of reinforcing the linkage inherent to the process approach in your quality system.

Following the RCA checklist shown in figure 5.1 ensures that things don’t get forgotten. Because it resembles a to-do list, people are more inclined to continue until the list is complete. This is particularly beneficial in those instances when the root cause of the problem is actually a combination of factors. If a customer receives the wrong revision of the field repair kit, you may have two issues:

• The instructions either have not been revised and/or the revisions have not been distributed. This is a breakdown in your document control process.

• There is a failure in the process you use to verify shipments against customer orders. This is a breakdown of the processes often grouped under the heading of “contract review.”

Were you to stop after you realized that there are older revisions of the field kit still on the shelf, you’d lose the opportunity to ask if there should have been more complete information supplied by from the service technician so the order could be matched to the right version of the product. Organizations have, as a matter of course, checks and safeguards in place so that mistakes don’t leave the building. When there’s a breakdown at one point, it’s appropriate to ask why the other fail-safe mechanism didn’t kick in.

Prior to using the form, you will have determined which areas you want to visit. You will have selected procedures and work instructions to help understand the requirements. You may have a general idea about what kind of records you need to look at. This is the clearinghouse for all the data you’ve gathered based from brainstorming, interviewing, and flowcharting. On this form, or on a separate sheet if you need the space, you should write what you reviewed, tested, inspected, researched, or analyzed and what conclusion you reached based on the evidence gathered.

It’s possible (and quite likely) that you will find that several blocks don’t apply. As with the cause-and-effect diagram in chapter 4, it’s appropriate to mark “N/A” in such a case.

Most records relating to communications and other interactions with customers are grouped into this category. These records include customer requirements, concerns, contracts, complaints, inquiries, and level of satisfaction and may be found in a variety of formats:

Customer returns

• Does the return material authorization (RMA) form provide adequate information? Why did the customer return the product?

• Is the product defective or simply not what the customer expected? What does the order indicate?

• What are the customer’s acceptance criteria for the product?

• Have you verified the customer’s finding? Is there a report that came back with the material?

• How many units were returned?

• Do multiple returns represent only one part number or product?

• Have other customers made similar returns? What does the RMA database show?

Customer complaints (unrelated to a specific return)

• Is there a delivery issue? Do the records show a confirmation of ability to meet the required delivery date?

• Is there a problem with technical assistance? Is there a database for incoming calls?

• Does the user manual or accompanying documentation have errors or ambiguities?

• Does this problem relate to a defect accepted as a one-time concession? Where are records of customer concessions kept? How are the concessions communicated?

• Was ...