- 519 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Materials Planning with SAP

About this book

Balance the art and science of materials planning! Learn how to use SAP ERP to calculate what, when, and how many items are required for production with this comprehensive guide. From portfolio management and policy setting to exception monitoring and inventory optimization, you'll see the complete manufacturing picture that materials planning paints. Once implemented, evaluate your materials planning to make improvements, and move your materials planning from routine to strategic!

Highlights include:

- Supply chain management

- Portfolio management

- Automatic and periodic policies

- Exception monitoring

- Inventory optimization

- SAP ERP

- Inefficiencies

- Key performance indicators

- Value streams

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part I

Materials Planning Basics

Being busy does not always mean real work. The object of all work is production or accomplishment and to either of these ends there must be forethought, system, planning, intelligence, and honest purpose, as well as perspiration. Seeming to do is not doing.

—Thomas A. Edison

—Thomas A. Edison

1Materials Planning Basics

Materials planning, sometimes called material requirements planning (MRP), is a system developed to control inventory and manage manufacturing processes, such as the planning of component or raw material availability. Before Joseph Orlicky came up with the concept of MRP in 1964, reorder point/reorder quantity (ROP/ROQ)-type methods such as Economic Order Quantity (EOQ) were used in manufacturing, procurement, and inventory management. When MRP arrived it partially replaced these policies with more flexible and (in some cases) more fitting planning modes such as deterministic planning, time-phased replenishment, and forecast based ordering.

Subsequently MRP was developed into manufacturing resource planning (MRP II), which further includes the functions of rough resource planning, master scheduling, capacity planning, and sales & operations planning. From here on, the software industry took on most of the functionality, and SAP ERP was born.

Evolving from the R/2 system of the 1980s, today’s SAP functionality in this area allows you to control inventory, schedule production, forecast customer demands, procure raw materials, manage capacities and resources, and watch your fill rates and service levels. SAP’s functions for materials planning therefore serve as the interface between demand and supply. As such, materials planning in SAP ERP is intended to primarily meet three objectives:

- Ensure materials are available for production and products are available for delivery to customers

- Maintain the lowest possible material and product levels in the warehouses

- Plan manufacturing activities, delivery schedules, and purchasing activities

These functions become more important as customers demand products faster than they can actually be manufactured.

As you’ll see throughout this book, the foundation of this materials planning system has four pillars:

- Automated portfolio management

- Intelligent policy setting

- Prioritized exception monitoring

- Continuous inventory optimization

As we explore a comprehensive materials planning system like the one described, these four topics will guide us in the pursuit of a standardized, effective, automated, and agile model to plan materials with standard SAP. Before we get started with the specifics, however, let’s go over the basic process of materials planning.

1.1The Process of Materials Planning

Because materials planning is so involved in the process of flowing product efficiently through the value stream, it should be designed as a set of repeatable tasks—a sequence of steps that considers demand and resource constraints as its boundaries within which optimization takes place. Materials planning lies between the functions of sales and operations planning to the north and external and internal procurement to the south. In other words, materials planning represents the connection between demand and supply.

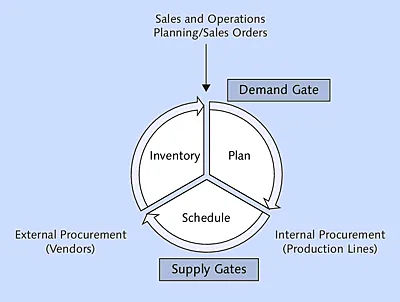

As information flows through this system, the planner has to respect the gates that divide the inventory, the plan, and the schedule (see Figure 1.1). This is important because there are terms and conditions which constrain the free flow of information and material. We all know that there are vendor terms and conditions, but do we also respect the conditions at the production lines? Or do we consider constraints for the materials planner when we put together a sales plan? Gate control in these areas is often forgotten or simply neglected because silos exist in which isolated planning takes place.

Figure 1.1Planning Cycle with Demand and Supply Gates

Materials planning, which is the central function within the planning cycle for sales and operations planning, production, and procurement, sits between the demand gate that represent the receipt of planned and actual requirements and the two gates for internal and external supply of manufactured products and purchased materials. As such, materials planning acts as an engine to fulfill the demand with the highest possible service levels and the lowest possible resource buffer (note that the resource buffer may be inventory but also capacity or time). This is quite a task to fulfill, and it becomes obvious that when things constantly change, the materials planner can’t produce good results. Take sales and operations planning as an example; often a consensus plan is loaded into MRP without a feasibility check. Consequently, the numbers a sales and marketing team comes up with for the next 6 to 12 months are by no means the automatically accepted supply plan—but that is exactly what we tell the SAP system when we load the resulting requirements into Transaction MD61.

Consequently, gate control has to be executed before we transfer the demand toward the material planner, and our Sales and Operations Planning department has to perform a rough resource check and negotiate with various fractions a feasible demand plan, considering all constraints, terms, and conditions. Then, through the critical decision of make-to-stock (MTS) versus make-to-order (MTO), requirements will build the starting point for the process of materials planning.

At some point in time, the planning procedure is executed. The MRP run performs a net requirements calculation according to the rules maintained in the material master and creates supply proposals. It also explodes the bill of materials (BOM) and therewith hands down required quantities and required dates so that a further net requirements calculation—and a subsequent generation of supply proposals—can be carried out for all materials needed to meet the primary demand. The planning run does all that automatically, in the background, based on the rule set, or policy, maintained in the four MRP screens of the material master.

Now we have a supply plan that is supposed to meet demand in the most efficient way. This supply plan consists of the order proposals, purchase requisitions or planned orders, and the associated exception messages that provide information about feasibility, order status, structural problems, timely problems, or inventory availability. The MRP controller’s job is to evaluate these exceptional messages, fine-tune the supply plan, keep the master data effective, and generally balance demand with supply from a pure planning perspective without any consideration of capacity constraints, supplier conditions, or forecast deviations.

So the last step in the process of materials planning is to hand over the MRP supply plan to the buyers and the production schedulers for application of constraints, terms, and conditions; for the assignment of suppliers and production lines; and for the actual execution of the plan.

And herein lies a big misconception about the job of materials planners. Expediting is not actually the job of the MRP controller. All too often we see materials planners being tasked with the actual procurement of raw materials or the determination of a production schedule. If one person has all of these roles, that’s not necessarily a problem, but materials planning will have to be finished before the MRP supply plan is handed over to Procurement and Production Scheduling, who then apply their constraints, terms, and conditions to arrive at the finite, short-term supply plan. The buyer or production scheduler should negotiate with the supplier or switch the jobs on the production line.

This delegation of duties is important to note. Materials planning is the process of balancing supply to a given demand (planned or actual) under the condition of planning parameters that are part of the supply chain strategy your company has defined—and not under the conditions of how well your suppliers deliver or how effective your production lines operate. If we mix materials planning with expediting and exceptional situations, we won’t derive a supply plan that is best on our management’s strategy and direction. If lines between what we’re striving for and what we’re actually achieving blur, it’s hard to measure the difference.

Effective materials planning will generate a supply plan that is in line with a well-thought-out and feasible supply chain strategy. Whether that plan can be executed well is an entirely different question, and partially dependent on the materials controller.

1.2The Materials Controller

Bad decisions in the area of materials planning cause lost money and customers. More specifically, if a materials controller procures insufficient quantities of raw materials, customer demand can’t be met, which reduces the company’s revenue. On the other hand, if excessive material is purchased or manufactured, money is wasted, and inventories pile up.

Therefore, the position of materials planner or, even better, materials controller is a very important one and contributes considerably to the success of a manufacturing or distribution company.

In the old days—and, scarily enough, in many of today’s materials planning departments—the materials controller always answered these questions:

- What do we need?

- When do we need it?

- How much do we need?

These are questions that when answered, only resolve part of the problem because they assume we know beforehand what to come and what our business can expect. But if there is even the slightest difference between the forecast and the real world—and uncertainty is certainly part of our lives—then we don’t really need that material at that time in that quantity. Instead, we ultimately need a different material, or at a different time, or in a different quantity. Therefore a better question to ask is, “Given our system and environment, where should we place resources (inventory, capacity, time) to have the best protection?”

This new way of planning resources and materials is called buffer management. And you need to design and place the buffer depending on the individual conditions (predictability, expense, scarcity, newness) of your materials.

But one buffer alone can’t protect your entire portfolio. What kind of buffer you need depends on the conditions and the situation the material represents. If you want to protect boats in a marina, as illustrated in Figure 1.2, you’ll have to consider what types of boats and what type of marina you want to protect. If you have a marina on a glassy pond, you really don’t need much, if any, protection, but if your marina is on Lake Michigan, you want to...

Table of contents

- Dear Reader

- Notes on Usage

- Table of Contents

- Part I – Materials Planning Basics

- 1 Materials Planning Basics

- 2 The Past and the Future of Materials Planning

- 3 Building Blocks of Materials Planning

- Part II – Materials Planning in SAP ERP

- 4 Principles of Effective Materials Planning

- 5 Prioritized Portfolio Management

- 6 Automated and Periodic Policy Setting

- 7 Intelligent Exception Monitoring

- 8 Sustainable Inventory Optimization

- Part III – Evaluating, Measuring, and Improving Materials Planning

- 9 Key Performance and Supply Chain Indicators

- 10 Traditional Inefficiencies

- 11 Improvement and Optimization Programs

- Part IV – Modeling Materials Planning

- 12 Scientific Modeling of the SAP Supply Chain

- 13 Examples from Industry

- 14 Conclusion and Outlook

- A Bibliography

- B The Author

- Index

- Service Pages

- Legal Notes

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Materials Planning with SAP by Uwe Goehring in PDF and/or ePUB format, as well as other popular books in Computer Science & Computer Science General. We have over one million books available in our catalogue for you to explore.