![]()

Technical knowledge

I owned a few technical books on construction before starting in a workplace, but every attempt to study them felt completely overwhelming, resulting in the book sitting dormant on the coffee table. If only someone could have highlighted a few introductory points, crossed out anything that went into too much detail, and torn out the pages that covered rarely used approaches! I’d have eagerly digested this summary, and it could have saved me so many daunting and naive moments. This is what I’ve tried to do for you here.

The following section covers what I think are the basic things I wish I’d known as a starting point. I’ve tried to use plain English and keep it as general and as simple as possible. Once you’ve got the gist of these basics, studying your technical construction manual for further alternatives and detail won’t seem so daunting. And when your employer asks, “Can you please check that the UB matches the brick course and that there’s flashing over it,” you can say, “Why yes, boss person, I can”.

![]()

#23 Stages of Construction (Residential)

Typical stages in a residential build may be referred to as:

1. Demolition – Only if applicable.

2. Site works – Clearing and levelling/cutting (excavating) of the site to desired starting levels.

3. Slab or base – Plumbing and electrical services are established, before the construction of the base structure of the house. Drainage, waterproofing and termite management systems are coordinated.

4. Framing – The structural frame of the walls and roof are constructed.

5. Lock up – The house cladding, roofing, windows and external doors are completed, so the home can literally be ‘locked up’. Plumbers and electricians can ‘rough-in’ services and then insulation can be installed.

6. Fix out/Fit off – The plasterboard, architraves, skirting and cornices are installed. Tiling is completed and joinery is fitted. Plumbing and electrical fixtures are connected. Painting is completed.

7. Landscaping – External works such as driveways, paving, pergolas and retaining walls may be completed while fix out is occurring.

8. Practical completion – The home is substantially complete and reasonably fit to move in. The Certificate of Occupancy (name varies depending on location) is granted.

9. Defects liability period – A set period for the builder to rectify any outstanding items or issues that may arise during this time.

![]()

#24 Overland Flow

Overland flow is a common industry term referring to the run-off of rainwater. Most projects will interfere with the existing site run-off paths to some degree, so the proposed overland flow path must be considered in the building and landscape design.

The National Construction Code dictates relative finished ground levels and slopes adjacent to buildings in relation to the rainfall of that area. These set out the minimum acceptable standard. I recommend considering the possibility of a future with a changing climate and more intense storms when working with these type of minimum standards.

It’s worth remembering that while an architect’s focus is primarily the building itself, built projects play a large part in the ecosystem and micro-climate around them.

![]()

#25 Footings and Foundations

The foundations and footings are the systems that transfer the heavy weight of a building to the ground.

The foundations of a site are the earth base that it sits on. The foundation will usually be given a soil classification. This determines how stable it is as a base, and informs the type, size and design of footings that can be used.

The footings are the constructed element that transfers the weight of the building on to the foundation. In Australia, footings are generally continuous, isolated or integrated.

A continuous strip or beam footing is a length of concrete, poured into a formed trench, with steel reinforcement inside. It then holds the weight of a wall that runs along it or a slab that bridges across to sit on it.

Isolated footings are individual pads, piers or piles, also with steel reinforcement. You can see these under traditional suspended timber floors in Australia, as they sit beneath each of the brick piers that support the framing.

Integrated footings are like continuous footings but are built into the slab system and poured as one.

![]()

#26 Concrete Slabs

Older homes in Australia were traditionally built with suspended timber floors. In the modern era, the concrete slab has become more popular for economic and thermal reasons.

There are three general types of concrete slab construction. These are slab-on-ground, suspended slab and pre-cast slab.

As its name suggests, a slab-on-ground sits completely on the foundation soil. A raft slab is a common type of slab-on-ground with an integrated system of beams spanning both directions that spread the load across the foundation. They’re described as ‘floating’ across the site, like a raft on water.

An increasingly popular variant of the raft slab is the waffle pod slab, which uses a grid of foam pods to form a similar system of beams that cross each other. Without the foam pods, from underneath the formed slab would slightly resemble a waffle. It’s generally quicker and less laborious than a traditional raft slab.

A suspended slab completely bridges its weight between structural footings or walls. It’s up off the ground, with a subfloor cavity under the slab. It’s formed by either temporary formwork, removed after the slab has set, or on a formwork that will remain in place once the project is completed.

A pre-cast slab is formed off-site then transported to the location and installed on footings. This system is more commonly used for larger commercial or industrial projects.

Note that cement is the binding powder in a concrete mix. Referring to concrete as cement is technically incorrect.

![]()

#27 Reinforcement

Reinforcement, often referred to as ‘reo’ in Australia, is steel that’s placed within concrete structures to increase their strength and stability.

Concrete is strong in compression, but not tension, whereas steel is strong in tension. Together these two materials complement each other structurally.

Reinforcement is also commonly used when connecting two structural elements. For example, a concrete slab may be poured with a line of bars left poking up to be cast in the walls later on.

In timber and steel framing, bracing plays a similar role. Either a steel angle strip or piece of timber plywood works in tension to stabilise the frame and increase the rigidity of the structure.

![]()

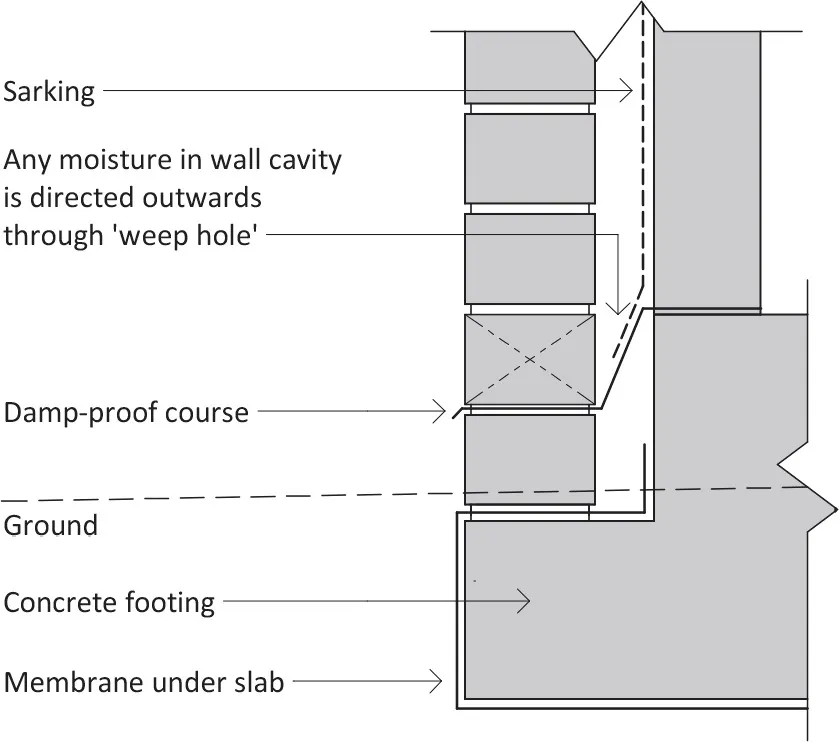

#28 Damp-Proof Course

Bricks and concrete may seem like fairly tough materials, but they are porous, so moisture can still move through them, even upward.

A damp proof course is a waterproof layer placed between a row, or course, of bricks to prevent rising damp.

The same logic applies to concrete, so you’ll also come across damp-proof membranes that are laid between concrete and the earth to prevent moisture moving into the structure.

![]()

#29 Condensation

Condensation is water droplets that form when water vapour comes in contact with a cool surface. If condensation forms in wall, roof or floor cavities it can lead to serious mould issues, ineffective insulation, and structural damage.

Condensation and the movement of water vapour are usually managed by the appropriate placement of vapour barriers or vapour permeable membranes. Vapour barriers are a material that blocks all vapour and condensation, while vapour permeable membranes will only block condensation or water droplets while allowing the passage of water vapour in damp air.

Historically, Australian houses were poorly insulated and very leaky and draughty, which meant that condensation was less of an issue. With minimum standards improving, beware of old-fashioned attitudes or a lack of awareness regarding water vapour migration in wall and roof cavities.

The most important thing to know about condensation and water vapour movement is that it varies between the many regions and climates in Australia, as well as site microclimates and even within ...