![]()

1 The Lean Journey

This book has a single purpose: to help you make Lean work in your organisation. It provides you with the key principles and tools needed for a lean transformation. It will guide your implementation and act as a reference guide for you to go back to as you advance on your lean journey. The philosophy will always remain, yet as new challenges arise, different tools will be required. In this book we have assembled the main tools, systems and principles we have found to be useful when applying Lean to manufacturing, as well as services, the public sector, IT operations, and the office. We wish you good luck in your journey!

1.1What is Lean….?

Lean is about moving ever closer to uninterrupted flow in the sequence of operations that deliver perfect quality – in other words – becoming more of a time-based competitor. ‘Flow’ is not only of physical products and services but also the information and designs necessary to run operations. This requires continuous improvement in three dimensions:

▪Waste reduction

▪Value enhancement

▪People involvement

Without all three, Lean will not survive. Through time, as conditions change, the emphasis may shift from one to another and back again. But always there should be elements of each and guided by a clear customer-related purpose. Note that the capabilities of your people need continuous development.

Especially important is that value must be defined in the eyes of the customer, in terms that are meaningful to the customer.

A ‘quick and dirty’ definition of Lean is ‘doing more with less’. This is of course directly in line with the definition of productivity (outputs / inputs). But this should be interpreted more widely as doing good for customers and stakeholders with less resources – materials, energy, pollution – to achieve ultimate sustainability.

The Lean Enterprise Institute states, ‘The core idea is to maximize customer value while minimizing waste. Simply, lean means creating more value for customers with fewer resources.’

In 2014, Quality Progress magazine defined Lean as ‘the permanent struggle to flow value to each customer.’ This concise definition captures several points:

▪There is no end point; it is a journey.

▪It is not easy.

▪Long term consistency is required.

▪It is about flow – and improving flow means understanding both customers and the system, and reducing impediments to flow.

▪The individual customer should be the focus. Not ‘mass’ but ‘one at a time’.

Roger Schmenner, emeritus professor at Indiana talks about ‘swift, even flow’, which is also a neat and succinct summary.

Masaaki Imai, pioneer of Kaizen, now thinks the core concepts are Flow, Synchronization, and Levelling, or ‘FSL’.

Gitlow has the useful concept that value is a function of time, place, and form – to make progress at least one has to be improved, if not all three. Time is delivery lead time. Place is to do with customer convenience. Form is to do with design and utility.

The TRIZ concept of value is the ratio of Benefits divided by Cost plus Harm. Benefits may accrue before, during, or after the event. Harm includes all the possible ‘victims’ – environment, energy, and safety as well as any social harm that may be caused.

1.2Lean Evolution

For many, Lean started with ‘tools’. Often, these were not even a set of tools but completely independent: 5S here, SMED there, kanban here and A3 there. But, like any set of tools, they are

there for a purpose, not an end in themselves. Like Michelangelo chipping away all marble that was not David, so Lean tools are there to chip away everything that does not enhance value for the customer. For a while, a pure tools approach is not a bad thing. Like Michelangelo’s original marble block, a lot can be removed with little skill. Then came Lean through Principles – often the 5 Lean Principles of Womack and Jones, or principles of self-help, respect, responsibility towards staff, customers and society. This is much better, and better still if systemically brought together.

But now some have begun to realise that ‘real’ Lean is behaviour-driven. What everyone does every day without being told. But how to get to this state of nirvana? Behaviour is built through confidence and security. An example would be pulling the Andon chord when a problem occurs and doing this as a habit, in the confidence that this will be supported and expected. No ‘lip service’. And the habit of using an experimental approach. Over time, with persistence, this builds the ‘world view’ – the things we take to be self-evident.

The most important behaviour is that, at every level, leaders are teachers – continually reinforcing the correct usage of the principles and the tools. Not relying on a 10-day Lean course, or a book, or intranet for their staff to learn the principles and tools – but by self-demonstration and coaching every day.

In some ways the word ‘Lean’ is an unfortunate one, because it has connotations of being manufacturing only (but by no means is confined to it), as well ‘mean-ness’ or ‘cutting back’, generally in terms of headcount. On the contrary, Lean is about growth and opportunity. For example, Toyota has grown not cut back. They have grown because they have capitalized on the huge advantages that Lean brings. It is better to grow into profitability rather than to shrink into profitability.

This leads to another important idea – that of ‘Lean Enterprise’. Womack and Jones have emphasized that Lean is concerned with enterprise not just with manufacturing. If you have already started on your Lean journey without involving design, marketing, accounting, HR, distribution, and field service, you will have to do so very soon or risk the whole programme. These functions have a vital role to play in answering what the organization will do with the improved flexibility, times, and the rest. If the answer is just ‘reduce costs’ management has missed the point. But the Lean enterprise also needs appropriate people policies, measures, accounting, design and new product introduction, supply chain activities, and service initiatives – perhaps ‘servitization’.

David Cochrane makes an excellent point: Lean, says he, is not what organizations need to do. Lean is what organizations should become by effective system design and implementation.

One way of understanding Lean is to view it as a (proven) approach to dispense with increasingly inappropriate ‘economies of scale’ and to adopt ‘economies of time’. To conclude, take Ohno’s Method:

1.Mentally force yourself into tight spots.

2.Think hard; systematically observe reality.

3.Generate ideas; find and implement simple, ingenious, low cost solutions.

4.Derive personal pleasure from accomplishing Kaizen

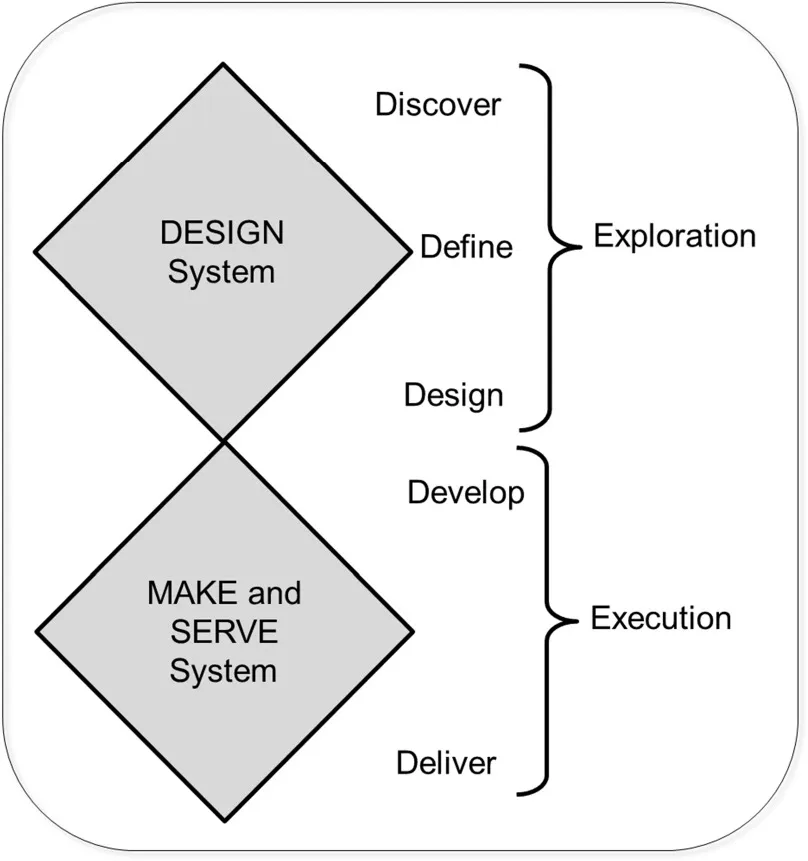

1.3The Double Diamond

The ‘Double Diamond’ is a useful concept that has been used for decades in value engineering, design (British Design Council), culture change, and service. A typical example is shown in the figure.

Within each diamond various alternatives are generated, considered, and the appropriate solution selected. Widen out the possibilities, then narrow the focus. Never go blindly after one solution – and then sometimes find it is a bad solution and all the work has been wasted.

Lean has traditionally been seen to apply in the lower diamond. But to confine Lean to Execution is increasingly inappropriate. Much waste, cost and effectiveness is built in during stages in the upper diamond. So the diamond concept is useful as Lean has extended into design (for example by Westrick and Cooper), into ‘3P’, into Lean software (for example ‘Lean Startup’), and into Lean Service (Bicheno).

Each diamond in the broad double diamond contains several diamonds or sub-phases. In the top diamond, for example, there is innovation design, and Production Preparation Process (3P). In the bottom diamond, the same widen-it-out-then-narrow-it-down would be recommended practice in A3, kaizen, value stream mapping, layout, and Six Sigma – to mention just a few.

So in this book increased attention is paid to the top diamond in comparison with the previous edition, and the methodology is recommended throughout.

1.4Lean, the S-curve and Innovation

Throughout history, every innovation has gone through an S-curve. Slow start, take off, fast growth, slowing growth, and maturity. Lean is no different. Neither is Six Sigma.

In the mid 1960’s the Olympic record for the high jump was progressing slowly. The dominant approach was the ‘Western Roll’. Enter Dick Fosbury with a radically new approach, initially scorned by his coach. But persistence won out and the ‘Fosbury Flop’ triumphed in the 1968 Olympics. From that moment other approaches were instantly outdated. The Western Roll could be improved upon continuously, but will never again win gold.

So it is with Lean: Kaizen and Breakthrough (or Kaikaku) need to work together. Breakthroughs often come from outside. As Steven Johnson has pointed out in “Where Good Ideas Come From”, they almost invariably involve ‘the adjacent possible’. Innovations are imported from adjacent areas. So Henry Ford used ideas from cattle slaughter disassembly, from ‘scientific methods’ and from the electric motor that enabled high consistency of parts and movement. Toyota built on Ford, but added ideas from the loom, from Juran’s quality ideas and Deming teaching, and from American supermarkets and trams.

Within each big S-curve there are little s curves – smaller innovations that acc...