- 239 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Shop Theory (Henry Ford Trade School)

About this book

This book is the revised 1941 mid-century guide on the basic principles of Shop from the prestigious Henry Ford Trade School, first published in 1934. The book was used by students attending Shop Theory classes and focusses on the historical development, principles of construction, and use, care, and operation of hand tools, precision tools, and the usual toolroom machines and equipment. The lesson sheet method of instruction, supplemented by lecture and discussion, is used. This compilation of the sheets, which was revised and brought up to date, should prove valuable as a reference for students and shop instructors.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Shop Theory (Henry Ford Trade School) by Dearborn, Michigan. Henry Ford Trade School in PDF and/or ePUB format, as well as other popular books in History & American Civil War History. We have over one million books available in our catalogue for you to explore.

Information

LATHE

The lathe is one of the most important machines in the machine shop. It removes material from revolving work by using suitably formed cutting tools of hardened and tempered steel or of alloy metals such as Carboloy, Stellite, etc.

1. What are the different types of lathes?

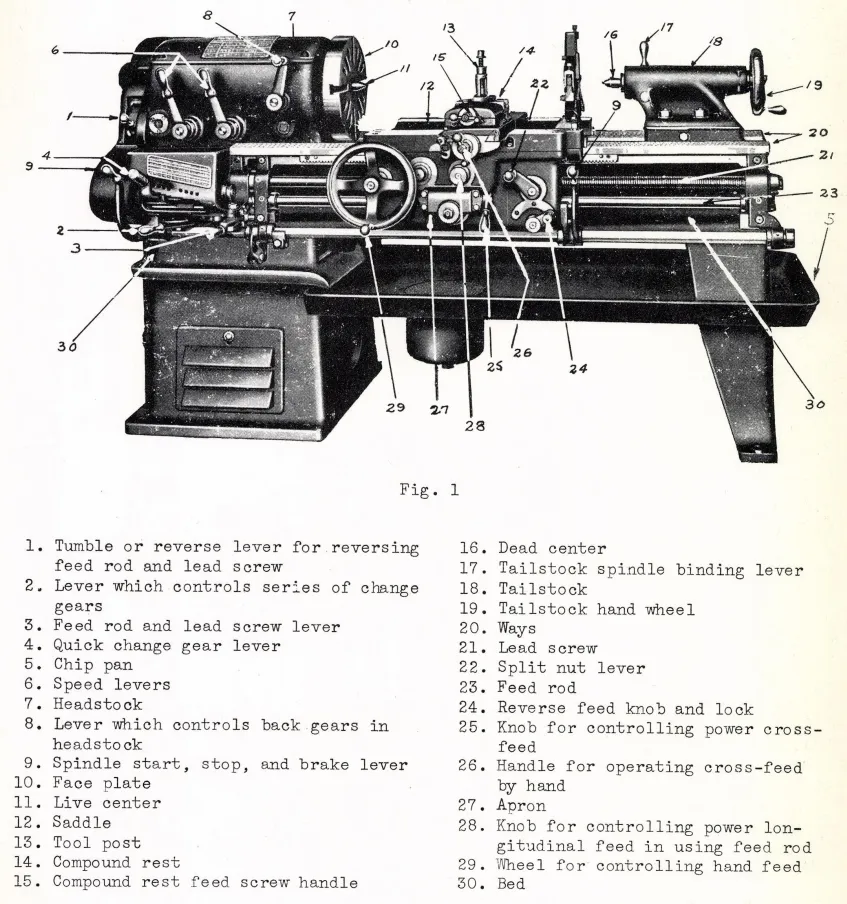

A. The engine lathe shown in Fig. 1 is used mostly in tool rooms. Because of its adaptability to various kinds of work it requires a great degree of skill to operate.

The vertical turret lathe is the fastest lathe for short or heavy work.

The horizontal turret lathe, commonly called the screw machine, is used extensively in the production of duplicate parts. Most of these machines are equipped with a pump and a metal basin so that a lubricant or coolant can be used.

The production lathe and the automatic screw machine are used for the production of small duplicate parts.

2. How is the size of the engine lathe determined?

A. Engine lathes vary in size, ranging from the small bench lathe of only a few inches to one many feet in length. The size of the engine lathe is based upon two measurements—the approximate largest diameter that can be revolved over the ways an:’ the total length of the bed. The actual size of the maximum swing is usually somewhat greater than the nominal size listed. For example, an 18 inch lathe may actually swing 18½ inches over the ways of the bed.

3. Name six important parts of the lathe.

A. Bed, carriage, headstock, tailstock, thread cutting mechanism, and feeding mechanism.

4. Describe the bed.

A. The bed consists of two heavy metal sides located lengthwise, with ways or V’s formed upon them. The bed is rigidly supported by cross-girths.

5. What is the carriage and what is its function?

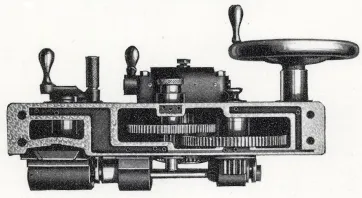

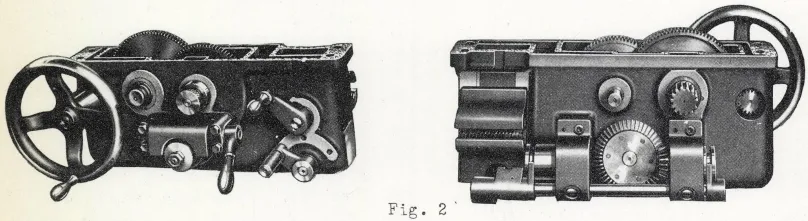

A. The carriage, consisting of the saddle and apron, is the movable part which slides over the ways between the headstock and tail-stock. The saddle has the form of the letter being bridged across the lathe bed to carry the cross-slide and tool rest, fitted to the outside ways, and gibbed to the bed. The apron (shown in the three illustrations of Fig. 2) contains the gears and clutches for transmitting motion from the feed rod to the carriage and the split nut which engages with the lead screw in cutting threads. The function of the carriage is to carry the compound rest.

Fig. 2

6. Describe the headstock.

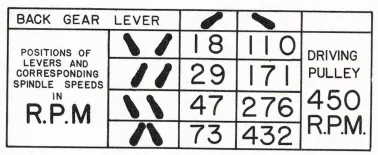

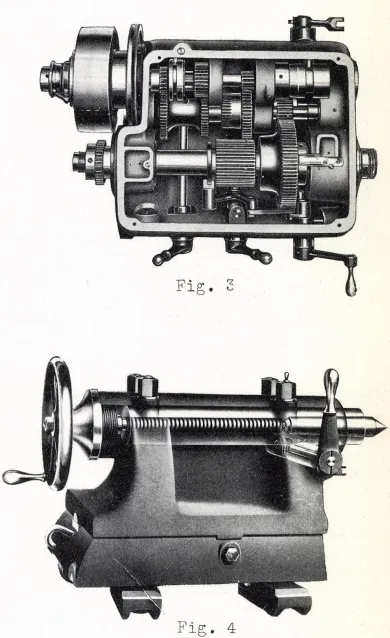

A. The complete headstock (Fig. 3) consists of the headstock casting, which is located on the ways at the left of the operator, the spindle in which the live center is rigidly held by a taper, and the necessary gears and mechanism for obtaining the various spindle speeds.

7. Describe the tailstock.

A. The tailstock (Fig. 4) is a movable casting located opposite the headstock on the ways. It contains the dead center, the adjusting screw, and the hand wheel.

8. What are the thread cutting and feeding mechanisms?

A. The thread cutting mechanism includes any gears or mechanism which transmits motion from the main spindle to the lead screw. The carriage movement is adjusted by the split nut on the lead screw, using the lever on the outside of the apron to move the split nut (see Fig. 2). The lead screw is used only for thread cutting, except on a lathe that does not have a feed rod. The apron on such a lathe is moved along by a spline in the lead screw instead of by using the thread.

The feeding mechanism is a train of gears (series of gears in mesh) which transmits motion from the headstock or main spindle to the feed rod, and also to the lead screw when it is being used. The motion is then transmitted from the feed rod to various gears in the apron. The feed gears are generally controlled by friction through small knobs located on the front of the apron. Fig. 5 shows the quick change gears used in securing the correct number of threads per inch in thread cutting or for varying the feed to suit different conditions. The plate indicates the position of the levers for producing the desired feed in thousandths or threads per inch.

9. What is the purpose of the compound rest?

A. The compound rest supports the cutting tool in its various positions. It may be swiveled on the cross-slide to any angle in the horizontal plane. Its base is graduated to 180°, or 90° each way from the center, and the feed screw collar...

Table of contents

- Title page

- TABLE OF CONTENTS

- ACKNOWLEDGMENT

- SHOP THEORY DEPARTMENT

- DECIMAL EQUIVALENTS

- FORMULAS AND DATA

- FORMULAE

- SMALL TOOLS

- RULES

- MICROMETERS

- VERNIER GAGES

- CHISEL AND CHIPPING

- HACK SAWS AND SAWING

- FILES AND FILING

- SOLDERING

- F CLASS QUERIES

- DRILLS AND DRILLING OPERATIONS

- TAPERS

- THREADS

- GEARING

- CUTTING TOOLS

- SHAPER

- LATHE

- GAGES AND GAGE BLOCKS

- HEAT TREATMENT

- GRINDING

- REQUEST FROM THE PUBLISHER