Pump Wisdom

Essential Centrifugal Pump Knowledge for Operators and Specialists

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Pump Wisdom

Essential Centrifugal Pump Knowledge for Operators and Specialists

About this book

Pump Wisdom

Explore key facets of centrifugal pump ownership, installation, operation, and troubleshooting

The Second Edition of Pump Wisdom: Essential Centrifugal Pump Knowledge for Operators and Specialists delivers a concise explanation of how pumps function, the design specifications that must be considered before purchasing a pump, and current best practices in lubrication and mechanical seals.

Readers will encounter new startup and surveillance tips for pump operators, as well as repair versus replacement or upgrade considerations for maintenance decision makers, new condition monitoring guidance for centrifugal pumps, and expanded coverage of operator best practices.

This latest edition of Pump Wisdom: Essential Centrifugal Pump Knowledge for Operators and Specialists includes expanded coverage of areas critical to achieving best-in-class pump reliability, including commonly encountered issues and easy-to-follow instructions for getting centrifugal pumps to operate safely and reliably.

This book also provides:

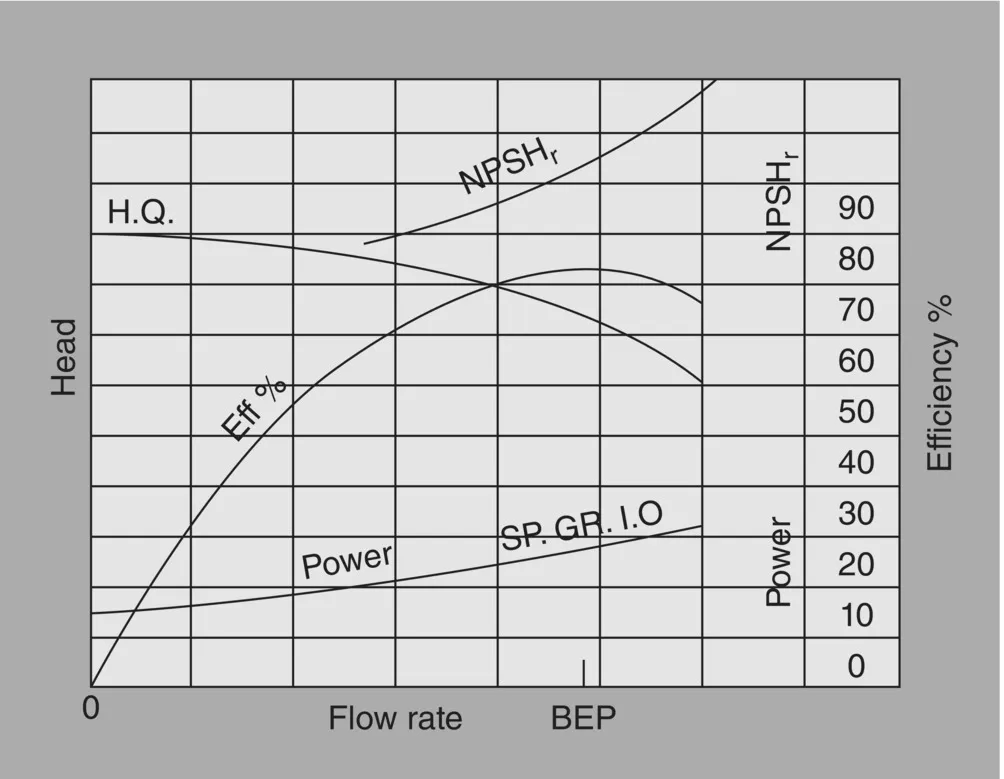

- Comprehensible and accessible explanations of pump hydraulics

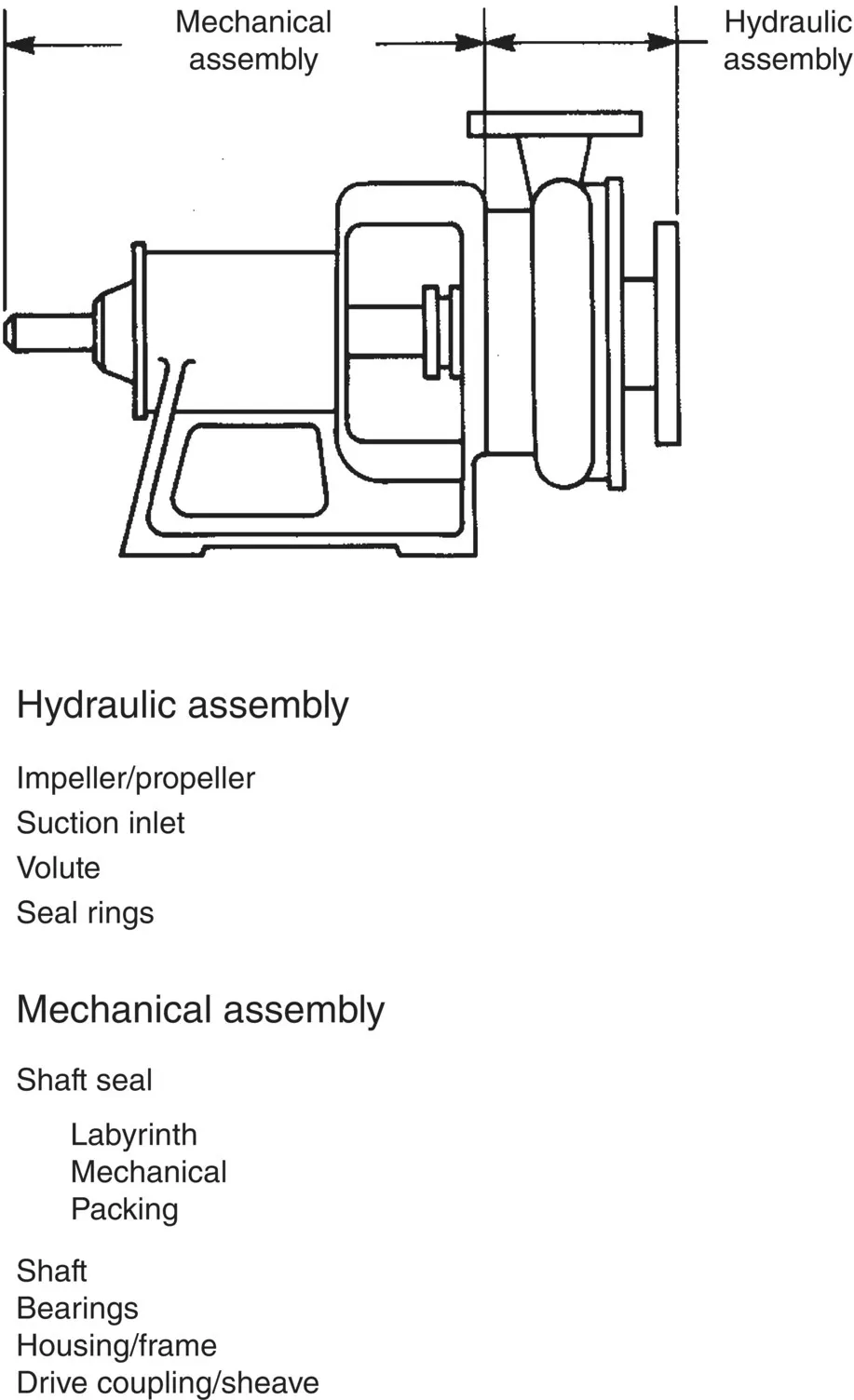

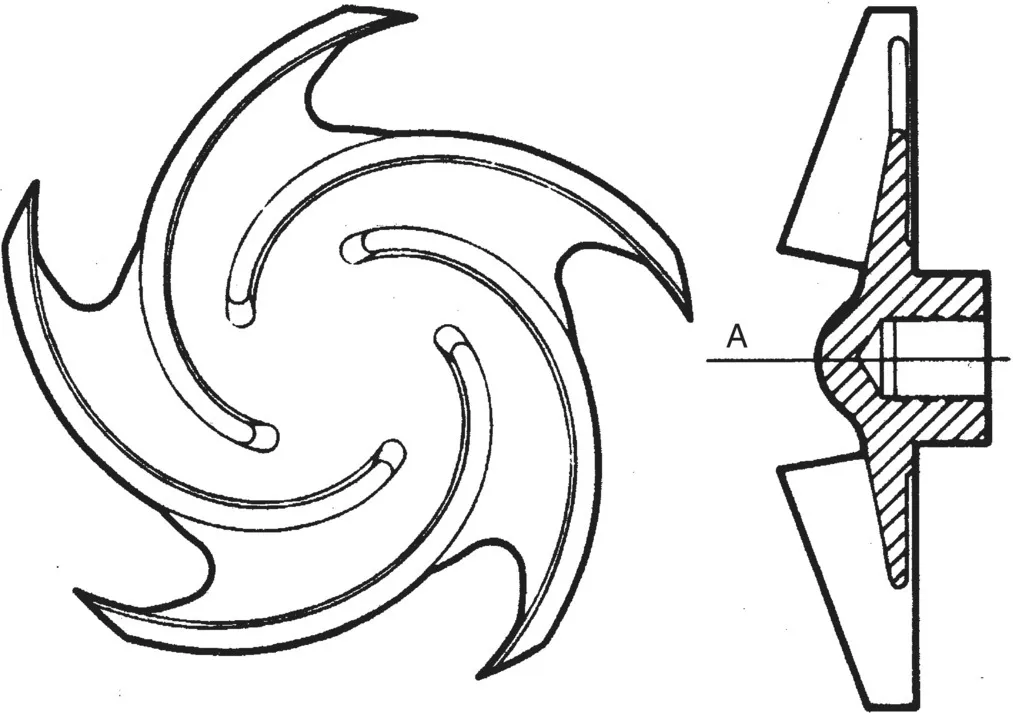

- Simple explorations of the mechanical aspects of pumps with coverage of bearings, seals, impeller trimming, lubricant application, and more

- Safety tips and instructions for centrifugal pumps

Perfect for chemical, petroleum, and mechanical engineers, Pump Wisdom: Essential Centrifugal Pump Knowledge for Operators and Specialists is also an ideal resource for operators, managers, purchasing agents, machinists, reliability technicians, and maintenance workers in water and wastewater plants.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1

Principles of Centrifugal Process Pumps

Pump Performance: Head and Flow

Table of contents

- Cover

- Table of Contents

- Title Page

- Copyright Page

- Dedication Page

- Preface

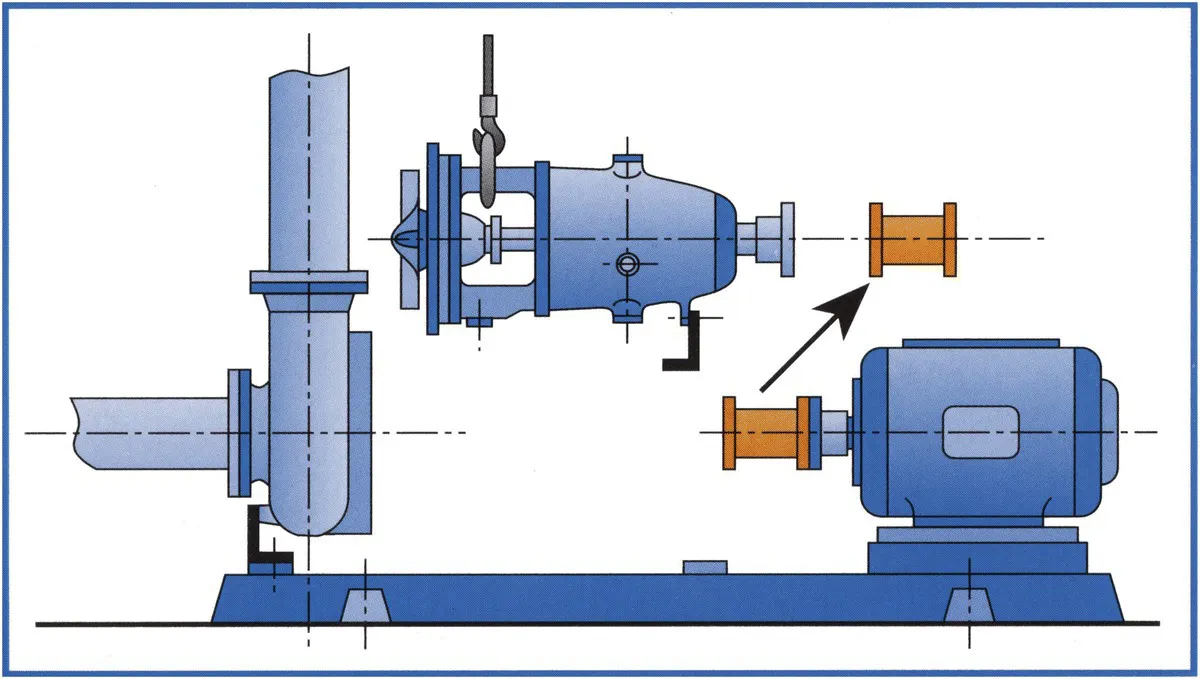

- 1 Principles of Centrifugal Process Pumps

- 2 Pump Selection and Industry Standards

- 3 Foundations and Baseplates

- 4 Piping, Stationary Seals, and Gasketing

- 5 Rolling Element Bearings

- 6 Lubricant Application and Cooling Considerations

- 7 Lubricant Types and Key Properties

- 8 Bearing Housing Protection and Cost Justification

- 9 Mechanical Sealing Options for Long Life

- 10 Pump Operation

- 11 Impeller Modifications and Pump Maintenance

- 12 Lubrication Management

- 13 Pump Condition Monitoring

- 14 Drivers, Couplings, and Alignment

- 15 Fits, Dimensions, and Related Misunderstandings

- 16 Using Failure Statistics and Root Cause Analysis Findings to Guide Reliability Improvement Efforts

- 17 Repair, Replace, or Modify?

- 18 Centrifugal Pump Monitoring Strategies

- 19 Final Thoughts

- Index

- End User License Agreement