Diagnosis and Fault-tolerant Control Volume 2

From Fault Diagnosis to Fault-tolerant Control

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Diagnosis and Fault-tolerant Control Volume 2

From Fault Diagnosis to Fault-tolerant Control

About this book

This book presents recent advances in fault diagnosis and fault-tolerant control of dynamic processes. Its impetus derives from the need for an overview of the challenges of the fault diagnosis technique and sustainable control, especially for those demanding systems that require reliability, availability, maintainability, and safety to ensure efficient operations. Moreover, the need for a high degree of tolerance with respect to possible faults represents a further key point, primarily for complex systems, as modeling and control are inherently challenging, and maintenance is both expensive and safety-critical. Diagnosis and Fault-tolerant Control 2 also presents and compares different fault diagnosis and fault-tolerant schemes, using well established, innovative strategies for modeling the behavior of the dynamic process under investigation. An updated treatise of diagnosis and fault-tolerant control is addressed with the use of essential and advanced methods including signal-based, model-based and data-driven techniques. Another key feature is the application of these methods for dealing with robustness and reliability.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1

Nonlinear Methods for Fault Diagnosis

1.1. Introduction

1.2. Fault diagnosis tasks

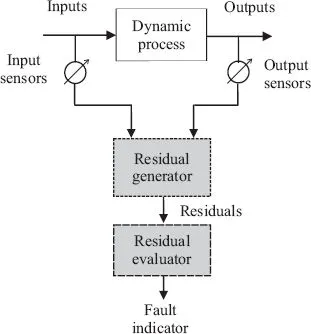

- 1) The residual generation module generates residual signals using the available inputs and outputs from the process under diagnosis. This residual (or fault symptom) should indicate that a fault has occurred. It should normally be zero or close to zero under no fault condition, and significantly different from zero when a fault occurs. This means that the residual is characteristically independent of process inputs and outputs in ideal conditions. Referring to Figure 1.1, this block is called the residual generator.

- 2) The residual evaluation module examines residuals for the likelihood of faults and a decision rule is then applied to determine if any faults have occurred. The residual evaluator block in Figure 1.1 may perform a simple threshold test (geometrical methods) on th...

Table of contents

- Cover

- Table of Contents

- Title Page

- Copyright

- 1 Nonlinear Methods for Fault Diagnosis

- 2 Linear Parameter Varying Methods

- 3 Fuzzy and Neural Network Approaches

- 4 Model Predictive Control Methods

- 5 Nonlinear Modeling for Fault-tolerant Control

- 6 Virtual Sensors and Actuators

- 7 Conclusions

- 8 Open Research Issues

- List of Authors

- Index

- Summary of Volume 1

- End User License Agreement