Selective Laser Melting Based Additive Manufacturing: Materials, Properties and Defect Analysis

Varthini Rajagopal1, Dinesh Kumar Rajendran2, *, B. Santhi3, Arjun R. Jagadish3 1 Department of Mechanical Engineering, Government College of Engineering Srirangam, Tamilnadu-620012, India

2 Department of Mechanical Engineering, National Institute of Technology Srinagar, Jammu and Kashmir -190006, India

3 Department of Mechanical Engineering, National Institute of Technology Goa – 403401, India

Abstract

Our work presents a comprehensive report on selective laser melting (SLM) techniques with a specific focus on the different material families compatible with the SLM process, the mechanical and microstructural characteristics, residual stress and defect analyses. The major process parameters that determine the geometric accuracy and post-treatment techniques that eradicate defects in SLM fabrication are also reviewed. Then, a keyword co-occurrence analysis is performed to determine the future research directions in the SLM. The results showed mechanical characteristaion of SLM, defect analysis of SLM, SLM fabrication of porous implants and bulk metallic glass production using SLM to be the four major domains in SLM literature.

Keywords: Additive manufacturing, Aluminum alloy, Biomedical application, Composite, Developing trend, Heat treatment, Hybrid processing, Liquid phase sintering, Mechanical properties, Mechanical properties, Metallurgical defects, Microfabrication, Microstructural evolution, Network analysis, Powder metallurgy, Powder-bed recoating, Process parameter, Repeatability, Reproducibility, Selective laser melting, Selective laser sintering, Spheroidisation, Titanium.

* Corresponding author Dinesh Kumar Rajendran: Department of Mechanical Engineering, National Institute of Technology Srinagar, Jammu and Kashmir -190006, India; Tel: +919865138376 E-mail: [email protected] INTRODUCTION

Selective Laser Melting (SLM) uses a laser with high density to melt and join metal powder in a particular shape traced by the laser source, thus forming the

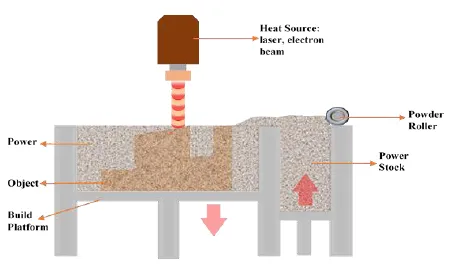

final product of near net shape. This process of manufacturing the product into the required shape is also called rapid prototyping, 3D printing, or Additive Manufacturing (AM) technique. This process is part of powder bed fusion (Fig. 1) and is similar to binder jetting additive manufacturing in which the binder is used to shape the powder particle that is later melted by sintering. In this process, a direct laser source is used to shape the powder into the required final product by direct melting. The major advantage of this process is that it is capable of producing 99.9% relative density of the as casted material with improved mechanical and metallurgical properties without weight addition or reduction. The various metallic materials processed in SLM are titanium, tungsten, aluminium, and copper; this has also opened the gateway for fabricating ceramic and composite materials with a high- density laser source with increased temperature

Fig. (1)) Powder bed fusion based AM.

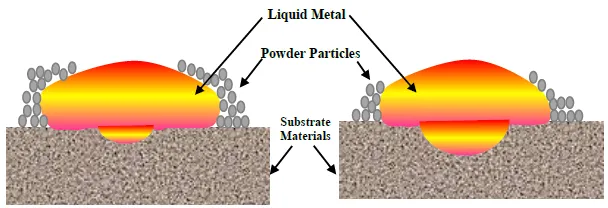

range. Yadroitsev et al. [1] studied the effects of laser power and scanning speed on single track formation anda reasonable negative correlation was found between optimal scanning speed and thermal conductivity of base material. Yan et al. [2] examined the influence of key factors, underlying mechanism formation and fabrication quality of single tracks. In addition to that, hatching distance and scan paths were simulated to identify the formed defects during SLM. Gu et al. [3] investigated the balling effects during the printing of stainless steel powder. The result indicates that lower laser power provides balling through coarsened balls possessing an interrupted dendritic structure. A further rise in volumetric density of energy input, lesser scan speed, a rise in laser power or a decrease in layer thickness minimize the tendency of balling. Matthews et al. [4] studied the metal powders denudation that is detected near the laser scan path and ambient gas pressure. Results provide new insights into denudation and formation of melt track which is essential for the minimization and prediction of surface roughness and void defects in SLM produced components. Chen et al. [5] developed the multiphase flow model to understand the denudation phenomena and physical mechanisms during the laser powder bed fusion process. The balling phenomenon in the SLM process is shown in Fig. (2). The SLM process plays a prominent role in bone tissue engineering and biomedical implant. The mechanical and biological requirements associated with bone scaffolds have been analysed. Different materials and processes adapted for scaffold have been deeply investigated [6]. Metallic implants have been noted to be promising and durable for human life. The most prominent metallic material for biomedical implants was found to be Ti-6Al-4V, specifically for biomedical implants. The lattice structure of Ti is used as a bone substile that passes through various design and testing approaches. The porous Ti material performs better than bulk metal though the mechanical strength differs; the elastic modulus is adjusted to match with the cortical bone [7].

Fig. (2)) Balling phenomenon in SLM process.

The research on metallic skeletal endoprostheses produced by SLM has been developed at micro and macro scales [8]. The growth of metal AM research can be partly attributed to the many benefits associated with the process. For instance, AM methodologies do not have the same degree of design constraints as traditional procedures. AM has a much higher degree of geometrical independence that enables mass customization of components. In addition, time, energy and material savings using AM decrease significantly compared to conventional production methodsThe most significant criterion is the overall effectiveness of the equipment (OEE), which needs to be higher than 70% with lower scrap prices at about 1000 ppm [9]. The SLM on NiTi alloy is considered to be a great support for research for understanding the features like shape memory effect and super elastic behaviour [10]. Additive manufacturing technology enables the production of complex structures with biomimicry characteristics, and has the potential to overcome the limitations of traditional manufacturing methods. Additive manufacturing by powder bed fusion has tremendous potential for manufacturing high-quality porous metal implants. There are two challenges associated with the powder bed fusion process, increased cost and maximum time taken for the production of the component [11].

The osseointegration and modulus of elasticity of bone are increased with Ti implants with the possibility to create porous complex; this lowers the cost and customizes implants through computer tomography making the patient more comfortable with the implants [12]. The implants are customised by design features like scaffolds, patent anatomy, and latticing. Alloying Ti implants produces less modulus and stress shielding for improving bone fixation and formation [13].

Among all, metallic cellular scaffold based implants are the best replacement for human bones with maximum durability and life. The 3D printing system enables the production of a highly porous component that enables tissue growth through the implant. This leads to many advantages, such as high build resolution, less material, high dimensional accuracy, clean build environment, and high customisability. Though various materials are being used, Ti-6Al-4 V has been found to be the best due to its biocompatibility, corrosion resistance and mechanical properties [14]. In SLM process, on controlling the process parameters, unique properties of the material, such as mechanical, thermal, acoustic and electrical, can be achieved. Gibson-Ashby model is used for the prediction of correlation between relative density and mechanical property of unit cell topologies [15]. The magnesium-based structural fabrication is in high demand in automotive and aerospace industries due to its low density and lightweight structure. The complex manufacturing of critical parts into the different assembled design is made easy by fabricating as a single component manufacturing process [16]. Thus, the introduction of additive manufacturing techniques like SLM eradicates the complex defects occurring in traditionally machined, formed and casted manufacturing components in electrical component manufacturing, automotive, aerospace and medical implants.

This also paves the way for the fabrication of ceramic and plastic materials apart from metallic components. The other difficulties in traditional manufacturing, such as customised size, creating porous design to reduce weight, manufacturing sequence, assembly and other processes, are completely controlled by the additive manufacturing process [17]. Based on the volume of fluid, method and discrete element, the multi physic model is developed for the SLM process including variables like heat transfer, flowability and solidification. The physical features like surface tension, vapour recoil, marangoni effect and radiations, have also been considered. The simulation clarifies that parameters depend anisotropically on both molten pool and remolten region dimension [18].

CLASSIFICATION OF POWDER BED FUSION PROCESS

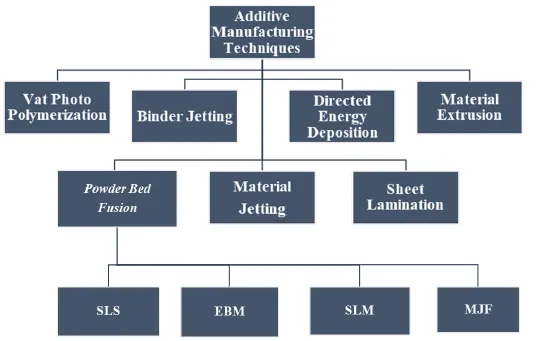

Powder Bed Fusion (PBF) manufacturing technique fabricates components with accuracy and precision. This additive manufacturing practice facilitates the built-up of a massive group of geometrically multifaceted products by means of a heat source, mostly laser or electron beams, to colloid fine powder particles layer-by- layer, therefore developing a solid part. Since PBF offers a range of viable technologies and materials, manufacturers can have a lot of design flexibility. The different Powder Bed Fusion methods (Fig. 3) notably include (i) Electron Beam Melting (EBM), (ii) Selective Laser Melting (SLM), (iii) Selective Laser Sintering (SLS), and (iv) Multi Jet Fusion (MJF).

Fig. (3)) Classification of powder bed fusion process.

Electron Beam Melting (EBM)

The high-energy electron beam is used for attaining fusion in EBM 3D printing, which in turn, results in less distortion due to less residual stress produced. On comparing to SLS, it can produce builtup layers faster with less energy. The major applications of this method are involved in industries like aerospace, medical, defence...