![]()

CHAPTER ONE

IN THE BEGINNING

Daniel Rudge

The ‘Rudge Whitworth’ company was created from a number of separate strands, all of which commenced in the nineteenth century. The first relates to Daniel Rudge, who gave it his name. Daniel (Dan) Rudge was born in 1841 in Wolverhampton. As a teenager he decided to ‘see the world’ and enlisted in the 38th Regiment of Foot – later to become the South Staffordshire Regiment in 1881.

Having ‘served his time’ in the army he followed a well beaten path to become the landlord of a pub. In his case it was the Tiger’s Head at 19 Church Street, Wolverhampton, on the corner of Bishop’s Street – now the site of an office block. A ‘blue plaque’ on the side of the building marks the place where the tavern stood, and details the connection with the cycle industry. In the surrounding area were several army friends who were becoming involved in the transport business, which greatly interested Dan. Former comrade Henry Clarke had set up a wagon-wheel business near the pub, which had a stable block behind it; Dan was therefore able to earn more than just being a publican by greasing cart axles, effecting repairs and adjusting brakes.

Rowley B. Turner brought over the first Michaux velocipede to England, arriving in Wolverhampton in 1868. Henry Clarke subsequently set up the Cogent Cycle Company, and another of Dan’s friends, Walter Phillips, was employed to ride them. Walter and his friend George Price soon persuaded Dan to start making his own ‘high bicycles’ (penny-farthings) to the former’s design then, with George Price providing the finances, production commenced in the building behind the pub (which led out into Bishop’s Street), with wheels supplied by Clarke. Dan noted that some of the other Wolverhampton cycle makers were producing poor quality work, so he set a high standard with the machines that he made.

He then became interested in racing the new machines, and at the first cycle race meeting in Wolverhampton in the Molineux Hotel Gardens’ cycle track in 1869 Dan himself won a race and several of his machines were successful in other hands. Orders for Rudge high bicycles were soon flowing in and the business expanded.

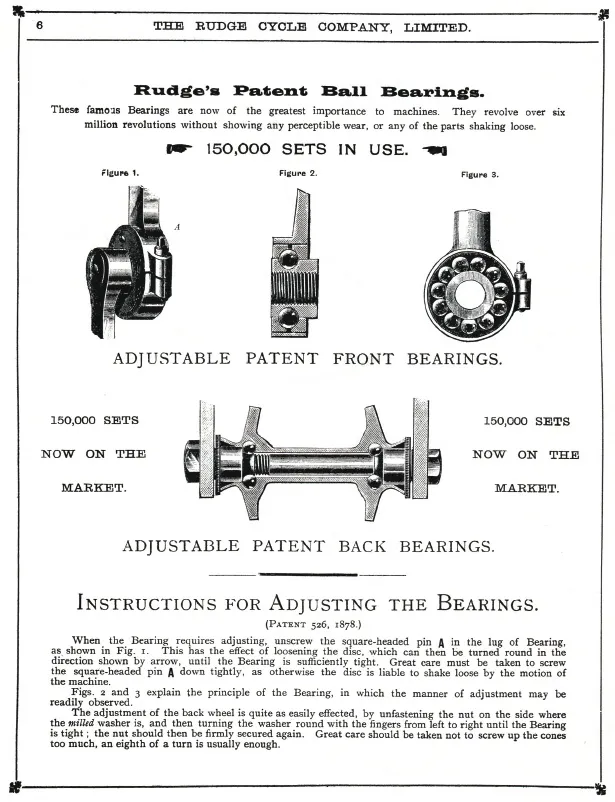

These machines were rather hard to start as they had plain bearings, but some French imports had ball bearings, which ran more freely. The problem was that the low-grade steels available at the time soon wore and the play at the rim of the driving wheel then became a danger. Dan patented an adjustable ball bearing (patent no. 526), which solved the problem. This was a great success and the Rudge machine was awarded a gold medal for excellence at the 1879 London Cycle Show. In many races the Rudge machines were required to start twenty or thirty yards behind the opposition because of their easy starting. This increased sales even more, and by 1880 Dan was employing 100 men.

Unfortunately Dan died on 26 July 1880 in a cancer hospital in Ealing, London. He left the business to his widow, but his children were too young to run it. Things could have ended there, but for the adjustable bearing patent and the name for good quality. Fortunately Walter Phillips became aware that George Woodcock, a Coventry solicitor, was interested in the business (particularly the bearing patent) and arranged for Dan’s widow to sell it to him in November 1880.

The Rudge adjustable bearing.

George Woodcock

After service in the Royal Navy, George Woodcock (born in 1837) qualified as a solicitor and then ran a very successful practice in Coventry. During the 1870s, by which time he had become involved in banking, he took an increasing interest in the embryo cycle industry and started buying up some of the local firms. The first of these was Smith & Starley, formed in 1872: the partners were James Starley and Borthwick Smith, who established the St Agnes works in Hale Street – this later became the centre of the Rudge Whitworth organization. The St Agnes works produced Europa sewing machines and Ariel cycles. James Starley, who has become known as the ‘father of the bicycle’, soon transferred the cycles to a new works in Spon Street. In 1877 the sewing machine manufacture moved to a factory in Crow Lane, which later became part of the Rudge Whitworth works.

In 1876 the company patented a machine called the ‘Coventry Lever Tricycle’, but a year later in a new patent, 972, the levers were replaced by pedals. This variation was then named the ‘Coventry Rotary Tricycle’, the components for which were manufactured by nearby Haynes & Jefferis. Solo cycles were also produced and sold under the names of Tangent and Swiftsure. By 1879 the latter company had become bankrupt, so George Woodcock took over both businesses; in 1880 he named the new company ‘The Tangent and Coventry Tricycle Company’.

One of the employees was James Henry Lawson, who patented a motorcycle with a ‘gas engine’ (patent no. 3913, of 1880); however, there is no proof that this was ever constructed. Had this happened it would have preceded Daimler and Butler by many years, although Lawson’s later Pennington was not a success. Lawson had also patented a safety cycle (patent no. 3934, of 1879), which the company produced but failed to sell. Currently employed then was James Kemp Starley, who went on to the Rover cycle company and successfully launched his own version of safety cycle. Sales of the Rudge safety cycle were attempted in France, where it was called the ‘bicyclette’; however, few sold – in spite of which the name has now become the French name for a safety-type cycle. The business also gave up the original cycle name Ariel, which was later much regretted.

The ‘hen and chicks’ tricycle in its Rudge Rotary form.

Many of the 100 or so Rudge employees from Wolverhampton transferred with the company to Coventry, and their skills greatly improved the machines leaving the works. George Woodcock integrated the three businesses under the titles of ‘D. Rudge & Co and Coventry Cycle Co’. Walter Phillips was rewarded by being appointed the works manager, as the whole enterprise prospered.

In 1885 one of the major investors decided to retire, so his share was sold to twenty-six private investors in the company, now called ‘D. Rudge and Company’, which continued the business. This was booming, as both Lawson and Richard Howell had become World Cycle Champions on Rudge high bicycles. Lawson persuaded the owners to offer shares in the company to the public, so in 1887 a new company was formed: Rudge Cycle Co. Ltd, with a share capital of £20,000. After opening a branch in Paris, the company was awarded a gold medal at the Great Exhibition in Paris in 1889. That year the catalogue proudly claimed that the company was ‘the oldest tricycle and largest cycle manufacturer in the world’. What could go wrong?

But in 1891 a short recession started in the cycle industry – and on 18 May, George Woodcock died, in the King’s Head Hotel in Coventry, which he also owned. By that time Walter Phillips was the general manager, but in 1893 he left to join the Humber Company, taking much business with him. And in the same year the assistant works manager, R. W. Smith, who was also the chief designer, left to become a founder of the Eadie Manufacturing Company and the Enfield Cycle Company. Thus although ‘the Rudge’ (as the factory was known in Coventry) had over 1,000 employees and modern premises, it had no strong leadership or innovation capability – and this was a recipe for disaster.

Some big claims for cycle and tricycle output.

Charles Pugh and his Sons

In 1891 there existed a company in Birmingham called Pugh and Sons, manufacturer of hinges, screws and builders’ ironware, headed by Charles H. Pugh. The sons became interested in manufacturing cycles, so a private company was formed under the name of the Whitworth Cycle Company. Charles Vernon Pugh (born in 1869) headed the business, while his brother John Vernon Pugh (born 1871) became the works manager and Fred Osmond the designer. In 1893 it became a private company called the Whitworth Cycle Co. Ltd. It had drive and a flair for publicity, but produced a fairly usual range of safety cycles. One noticeable item was the trademark: a raised red hand superimposed on a cycle wheel (no. 156827).

During the year discussions took place with the Rudge directors, which resulted in what they described as ‘a coming together on an equitable basis’. This took place in October 1894, and the new company was named Rudge Whitworth Ltd. Cycle assembly was centred at the Rudge works, while components were still made in Birmingham. The cycle trade slump was ending and the amalgamation had saved the company, so production soon expanded rapidly.

The workforce of the new company fitted in well, with many components being manufactured by them in the old Whitworth factory and the assembly of all machines in Coventry. The top management was soon in place, but there was a surplus of middle managers. However, the Rudge system of local depots selling direct to the public was retained and expanded, which provided jobs for more managers.

Charles Pugh became the chairman and managing director, as well as chairman of C. H. Pugh Ltd and Lanchester Motor Company Ltd. His brother John Pugh was nominally the works manager but was seldom on the shop floor, and was later appointed works director in October 1900. Work was later supervised by a new works manager, the former works superintendent, Victor A. Holroyd, who played a large part in the later motorcycle production.

Also at this time (1894) the company introduced a new name to put on the lower quality, cheaper machines to get rid of old stock. This was ‘Crescent’, a name that had been used before the amalgamation on machines sent to America. It would also reappear later on cheaper motorcycles.

Harry Rudge and Charles Wedge

Before moving into the twentieth century, however, there is a final strand of the story to add, involving Daniel’s son Harry. Too young to take over the company when his father died, he went to work for Humber when he left school. This gave him the knowledge of cycle production and distribution. In 1891 H. G. (Harry) Rudge and C. E. (Charles) Wedge formed Rudge Wedge and Co with a factory in Wolverhampton. This produced a range of cycles, mostly for the trade, as they could be supplied without badges for a local dealer to sell as his own. Later on some of these were supplied assembled with obsolete Rudge Whitworth parts which were obtained cheaply.

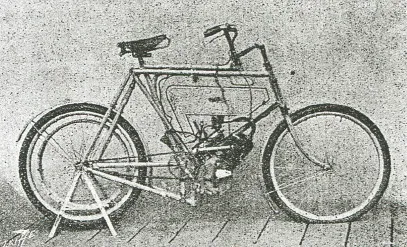

A regular exhibitor at the Stanley Cycle Show, in 1902 their stand introduced the Rudge Wedge motorcycles. These were listed as 1¾ and 2½hp machines, with the Minerva engines mounted on the front down-tube of a frame similar to their carrier bicycle, but without the basket. By the Crystal Palace Show in February 1904 a machine with a new frame was exhibited on the stand of H. M. Hobson. This involved a double frame joined by four springs so that the rider was ‘isolated from road shocks’. Unfortunately there was no form of damping, and as the machine was taller than was usual, road holding was reported to be not very good.

Although no Rudge Wedge motorcycles are recorded as having survived, it must be remembered that the company sold their products to the trade for them to be locally labelled. It is therefore quite likely that one or two may be still in use under the name of a local cycle dealer. This does not apply to the spring frame machine, which would be easily identifiable and probably did not progress beyond the prototype seen at the show.

The Rudge Wedge concern ran into difficulties during the cycle trade slump of 1906, so it made sense for Rudge-Whitworth to take over the business. By the end of the decade the company had three levels of cycle – most expensive was the Rudge, middle priced the Crescent, and the cheapest the Rudge Wedge. A number of cycle dealers reported that they met ‘Mr Rudge’ at the Coventry factory when they called to purchase stock, believing they had met the founder, not his son. Harry Rudge remained a senior manager until he died in 1924.

The Rudge Wedge sprung motorcycle.

Rudge Whitworth versus Werner

Meanwhile in 1903 the Rudge Whitworth Company was becoming involved in a dispute with the Werner Company in England. It all started when Mr Telford, the Rudge Johannesburg depot manager, was approached by the Werner Company and asked if he would like to sell their machines. As Rudge did not offer powered machines there was no conflict of interest, so the company in Coventry signed a contract with the UK Werner branch to take thirty-six machines that were sent to South Africa for sale as sole agents in the territory.

It all went wrong when it was discovered that there were other Werner machines being sold there at a lower price. John Pugh refused to pay the balance of £378 due on the machines, so the matter of breach of contract finished up in court in the King’s Bench Division on 17 November 1903. The case came to a standstill when both Werner Motors Ltd (UK) and Werner Frères (Paris) claimed that they had not sent the twelve cheaper machines that caused the dispute, to South Africa. The case was postponed and subsequently settled out of court. After this experience the company concentrated on cycle production and left motorcycles to others.

Between 1905 and 1906 the factory expanded with new buildings in Spon Street, Coventry, which became the centre of wheel production. At this point the company looked towards the growing car industry and its problems with wheels. The normal car wheel followed cart technology, so that when a wheel had to be removed, it included the hub, leaving just the axle. But frequent punctures resulted in much dust and grit being acquired by the hub, to the detriment of the bearings. Another option was the detachable wheel rim, but this could result in it becoming well out of balance.

John Pugh came up with a solution, where the wheel hub became a separate item with a splined outer cover, the remainder of the wheel having a matching internal spline, being retained by a single central hexagon nut. For racing this was replaced by a wing nut, which made the assembly quickly detachable, or ‘QD’ (patents nos. 12273 and 22868 of 1908). In the 1908 car TT, twenty-one out of the thirty-five starters had Rudge wheels, and only one finisher did not. S. F. Edge and his Napier set many records at Brooklands using these wheels – so their future was assured.

![]()

CHAPTER TWO

GETTING STARTED

The Prototypes

The Rudge Company was by this time one of the largest cycle manu...