- 224 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Tuning and Modifying the Rover V8 Engine

About this book

This is the ultimate book for any enthusiast or professional who is tuning or modifying the Rover V8 engine. This essential read covers all aspects of tuning this versatile and much-loved engine, with an emphasis on selecting the correct combination of parts for your vehicle and its intended use. Topics cover the short engine; cylinder head modifications and aftermarket cylinder heads; camshaft and valve-train; intake and exhaust systems; cooling system; carburettors and fuel injection; distributor and distributor-less ignition systems; engine management; LPG conversions and, finally, supercharging and turbo-charging.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER 1

ENGINE REQUIREMENTS AND SPECIFICATION

Before deciding on the specification of your engine build, or spending money on your existing engine, it is important to decide exactly what you require the engine for, and which characteristics are particularly important to you. By establishing your requirements at the beginning you will spend less of your hard-earned cash reaching your goal than if you change the requirements over the course of building or modifying your engine.

Be honest with yourself about your requirements. What are your priorities and where are you willing to compromise? Is maximum performance your main priority? Do you require good performance but also reasonable fuel economy and reliability? Does your engine have to meet certain emissions criteria? Is your vehicle likely to suffer from traction or transmission limitations? All engine specifications involve compromise in one or more areas. The aim is to balance these various compromises to suit your needs.

Planning your engine build carefully is also essential to ensure that you do not mismatch the various components: for example, spending money on big-valve cylinder heads but fitting an intake manifold that will not allow the heads to flow to their full capability; or fitting heads, intake and valvetrain that are capable of producing power up to 7,000rpm, but being limited by a crankshaft that will break at 6,200rpm. This may seem obvious, but many of us (authors included!) have been guilty of building or modifying engines in this way, costing more time and money in the long run to achieve the same desired result once the various limitations have been resolved.

PERFORMANCE

You have to be truthful with yourself about the type of ‘performance’ you require. Is there a particular peak horsepower figure that you are looking to achieve on the rolling road? A quarter-mile time you are looking to obtain? Or are you after the most significant ‘seat of the pants’ improvement within a given budget or specification?

Measuring the performance of an engine is a controversial topic and far from straightforward. This performance is usually measured whilst the engine is still in the vehicle, using a chassis dynamometer, drag strip, stopwatch or accelerometer. Measuring engine performance in the vehicle will obviously introduce a lot of potential for error, through transmission losses, rolling resistance, traction issues, driver reaction time, gear ratios, vehicle weight and aerodynamics. These errors must be correctly calculated to ensure an accurate measure of engine performance. A properly calibrated engine dynamometer is therefore a more accurate way of measuring the performance of the engine, with the torque being measured directly at the flywheel or crankshaft.

More often than not people focus on the peak horsepower or peak torque, but 99 per cent of the time the engine is not operating at this point, even when at full throttle. Unless we are purposely building a circuit-spec race engine with a narrow power-band, what we should focus on is the torque at the point you fully open up the throttle, until the point you let it off. Most drivers will be able to drive faster with an engine that has a broad spread of torque (a ‘rally-spec’ engine) than they would with the circuit-spec engine, even if the circuit-spec engine has more peak horsepower. The engine with the broad spread of torque will always feel more powerful, even to a racing driver.

Dyno screen showing ‘before’ and ‘after’ tuning.

Rover V8 on engine dyno. ROLAND MARLOW, AUTOMOTIVE COMPONENT REMANUFACTURING LTD

Deciding the engine speed range in which you want most of the torque (and by extension horsepower) to occur is a key part of the engine specification. The Rover V8 has a relatively ‘flat’ torque curve, but can be tuned for higher rpm torque if the engine builder is willing to sacrifice some lower rpm torque, drivability, and engine longevity. Likewise, if the application requires additional low rpm torque (for example off-road, towing) the Rover V8 can be tuned to suit if you are willing to sacrifice some higher rpm power and drivetrain longevity.

The weight and available traction of the vehicle being used also plays a key part here. With a lightweight sports car or kit car (for example TVR, Marcos, Westfield) not only is it acceptable to sacrifice some lower rpm torque for higher rpm power, it is often advantageous, as the Rover V8 usually endows these vehicles with an excess of torque at lower engine speeds. This leads to traction issues, making it difficult for the driver to consistently extract the maximum performance out of the vehicle at lower engine and vehicle speeds.

Another consideration is the speed at which the engine itself is able to accelerate. Factors such as low reciprocating assembly weight, low frictional losses, lean-best torque fuel mixture, optimum ignition timing, optimum valve timing and high port velocities all help the engine’s reciprocating assembly to accelerate quickly through the rpm range. Interestingly the Germans have a single word that best describes this: Beschleunigung-sleistung, which means ‘acceleration power’. An engine might have a high horsepower or torque figure – at, say, 5,000rpm – but if it takes twice as long for the engine to accelerate to that engine speed it will not perform so well in real-world terms.

Chassis Dynamometers

Most of us will use a chassis dynamometer (aka rolling road) to measure the performance of our Rover V8-engined vehicle. Many of us are aware that horsepower and torque figures not only vary between different cars, but also between different dynamometers, so we will briefly discuss some of the different methods of measuring horsepower and torque via a dynamometer to try and get a better understanding of what it all means.

The definition of horsepower is well publicized, but it is still worth printing the formula here to remind us that horsepower is a function of torque and engine speed:

Torque is the direct force that the engine applies to the drivetrain, or the direct force that the wheels apply to the ground – we will look at the differences later. Horsepower is usually more relevant to us, as this is a measurement of the work done by the engine or wheels in a given amount of time – this governs the rate of acceleration.

Car manufacturers usually always quote horsepower and torque figures at the engine’s crank or flywheel; this is measured directly with the engine on an engine dynamometer. During testing some car manufacturers will use an engine that has been built to a better standard (blue-printed) and will not fit various ancillaries (including alternator, power-steering pump, and so on) to give higher publicized performance figures – TVRs of the 1990s are a prime example of this. Unfortunately there is not just one dynamometer measurement standard, either: common standards currently used include DIN 70020, SAE J1349, ISO 1585, and more besides. Different standards will give slightly different horsepower and torque figures, so it can be seen that there is already considerable variation between different horsepower and torque figures, even when measured directly at the flywheel or crankshaft.

V8-powered Westfield.

Westfield with 4.3-litre Rover V8.

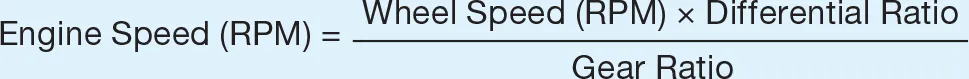

Chassis dynamometers (or rolling roads) measure torque at the wheels or hubs, instead of at the engine’s crank or flywheel, though the engine speed is still used to calculate ‘wheel horsepower’. With a two-wheel drive vehicle using a manual gearbox, the difference between the wheel speed and engine speed can be very easily calculated using the differential (final drive) ratio:

If run in a 1:1 gear (for example, fourth gear), as is correct and normal practice where possible, this simplifies the calculation even further:

Engine Speed (RPM) = Wheel Speed (RPM) × Differential Ratio

However, dynamometer operators often use the dyno software to calibrate the wheel speed to the engine speed, making it much simpler with automatic and four-wheel drive transmissions.

The horsepower or torque figures measured at the wheels or hubs are always lower than the figures measured at the flywheel – this is due to transmission losses. Transmission losses vary between different vehicles, and depend on a number of different factors, including number and type of differentials, type of gearbox, and viscosities of oil used in the drivetrain components:

Flywheel Horsepower = Wheel Horsepower + Transmission Losses

There are a few commonly used methods for estimating transmission losses, but as described, they are just estimates, adding even more variability between different rolling-road figures.

Many rolling-road operators will apply a transmission correction factor, in the form of a simple percentage multiplier, to the wheel horsepower and torque figures in order to provide the customer with flywheel horsepower and torque figures.

Some rolling roads do attempt to calculate transmission losses by measuring the horsepower used during a ‘coast-down’ phase, but this is still not accurate, as the losses are being measured with the gears within the differential and gearbox loaded on the opposite side to when the transmission is under maximum load in the forward direction. Interestingly, when we were using a local eddy-current type of rolling road we consistently recorded coast-down losses of about 45bhp at peak horsepower on a wide range of two-wheel-drive TVRs with a range of different manual transmissions, regardless of actual engine output. In other words, a TVR with 200bhp had virtually the same transmission losses as a TVR with 400bhp. This completely contradicts the idea that transmission losses are a simple percen...

Table of contents

- Cover

- Title

- Copyright

- Contents

- Dedication and Acknowledgements

- Introduction

- 1. Engine Requirements and Specification

- 2. Short Engine

- 3. Oil System

- 4. Cylinder Heads

- 5. Camshaft

- 6. Valvetrain

- 7. Intake System

- 8. Exhaust System

- 9. Cooling System

- 10. Fuel System

- 11. Ignition System

- 12. Engine Management

- 13. Liquid Petroleum Gas

- 14. Forced Induction

- Appendices

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Tuning and Modifying the Rover V8 Engine by Daniel R Lloyd,Nathan J Lloyd in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Automotive Transportation & Engineering. We have over one million books available in our catalogue for you to explore.