Cooling marine engines can be accomplished using either air or water. Air cooling is generally only suitable for small capacity engines that do not develop large amounts of power (and therefore heat), and is particularly useful on the inland waterways where weeds and rubbish can quickly block a water inlet strainer causing a water-cooled engine to overheat. With air cooling the only requirement is to provide an adequate supply of cool fresh air, and the engine will happily run at a reasonable temperature.

It must be stressed that only engines designed and properly equipped for air cooling can be used as such, because they will have been designed with ducting and finned flywheels to promote a rapid flow of air around the hotspots of the block. The size of the air-intake vents makes it difficult to achieve a very quiet engine installation, and the use of a dry exhaust also contributes to the noise. However, in areas of heavy water pollution the simple air-cooled engine has a lot to offer in terms of ease of maintenance and lack of corrosion.

Today, modern engines are almost universally water-cooled using heat exchangers or keel cooling to ensure that only clean water with added corrosion inhibitors is circulated through the engine block. The addition of anti-freeze and corrosion inhibitors to the water ensures that the internal water passages of the engine have year-round protection.

Raw water cooling takes the water straight out of the river or sea to circulate through the block, and is still used on some petrol engines; it is mainly installed in imported American sports boats that were originally destined for freshwater lake use. The corrosion and cold running problems that raw water cooling generates, particularly in salt water, make it less attractive except where the very lowest initial costs are necessary.

Direct or Raw Water Cooling

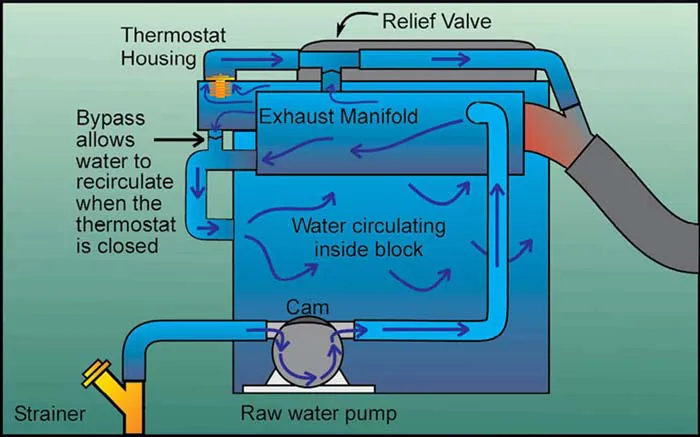

The main difference between fresh water and raw water cooled engines is that there is no header tank or heat exchanger fitted to these engines. Direct cooling that takes raw water directly from the sea or river, circulates it round the engine block and finally discharges it overboard – usually via the exhaust pipework – is a cheap, short-term solution to engine cooling and there are many drawbacks to the system. Particularly important is the problem of running temperature. It is not possible to use a standard thermostat to allow the engine to run at its correct temperature of around 80°C, as this will eventually cause severe blockages to the water passages from impurities and silt building up on the walls of the cooling system passages.

Schematic layout of a typical raw water cooling system.

The usual recommended working temperature for a direct-cooled engine is around 54°C, and this causes minor sludging of the oil as it can never achieve its optimum working temperature; the result of this is increased engine wear. The low temperature also means that items such as calorifiers for domestic water heating do not work as effectively as with freshwater cooling, but the last and most important point is that corrosion products from the hot raw water are continually attacking the engine internals as it impossible to add inhibitors to the water. The entire cooling system must also be drained during the winter months to prevent damage from freezing, as anti-freeze cannot be added other than during the lay-up period due to the lack of a header tank.

Raw water cooling equipment will usually consist of an impeller-type water pump and water-cooled manifold plus a marine gearbox, either mechanical or hydraulic, and a gearbox oil cooler if required.

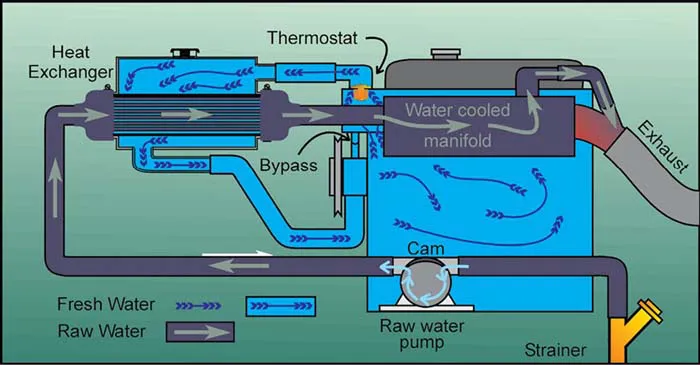

Indirect or Freshwater Cooling

None of the above-mentioned problems occur with indirectly cooled engines, which have a separate freshwater supply from a header tank that provides clean water to the engine block in the manner for which the engine was designed. This means that anti-freeze and corrosion inhibitors can be added to the freshwater supply, preventing the problems that beset raw water-cooled engines. They can also use a standard thermostat and run at their proper designed temperature for maximum efficiency and long life, while also supplying free hot water for the galley from a calorifier if required. The relatively modest extra cost is therefore well worth considering. Additional equipment required for indirect cooling includes a heat exchanger (often combined with the water-cooled manifold) and an engine oil cooler if required.

The much preferred freshwater cooling system.

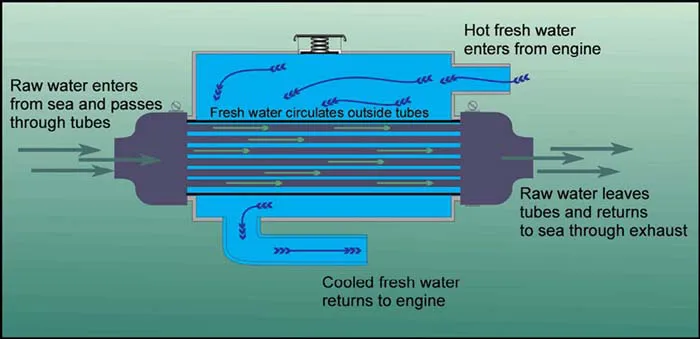

The Heat Exchanger

Heat exchangers, which on many engines are combined with the water-cooled exh...