eBook - ePub

Bearing Capacity Of Roads

A. Gomes Correia

This is a test

Share book

- 800 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Bearing Capacity Of Roads

A. Gomes Correia

Book details

Book preview

Table of contents

Citations

About This Book

This book is an outcome of the sixth conference on bearing capacity of roads and airfield held in Lisbon, Portugal. It focuses on railway tracks and covers following topics: bearing capacity policies, concepts, costs and condition surveys; analysis and modelling; design and environmental effects.

Frequently asked questions

How do I cancel my subscription?

Can/how do I download books?

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

What is the difference between the pricing plans?

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

What is Perlego?

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Do you support text-to-speech?

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Is Bearing Capacity Of Roads an online PDF/ePUB?

Yes, you can access Bearing Capacity Of Roads by A. Gomes Correia in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.

Information

Analysis and modeling

A Simple Damage Approach to Modelling Fatigue in Bituminous Materials

DOI:10.1201/9781003078814-11

ABSTRACT: Results from laboratory fatigue testing indicate that the effective stiffness modulus of asphaltic material can be reduced significantly under repeated loading without the presence of visible cracking. This indicates that damage is accumulating in the asphaltic material thus reducing the effective volume able to carry the applied load (and hence reducing the effective stiffness modulus). Damage mechanics characterises the state of a material under mechanical loading by a dimensionless scalar variable (known as damage). This paper describes the application of continuum damage mechanics in a simple way to model fatigue of asphalt mixtures. A specimen for uniaxial testing has been developed and a set of stress controlled fatigue tests have been performed over a range of temperatures and stress levels. The results have been used to determine a simple evolution law for the rate of damage accumulation. Trapezoidal cantilever (2-point bend) tests have also been performed and the results have been compared to results from the uniaxial test.

KEYWORDS: Damage mechanics, fatigue cracking, stiffness reduction, uniaxial test

1 INTRODUCTION

There are many different approaches to modelling fatigue and fracture in bituminous materials, ranging from simple models (e.g. tensile strain) to more complicated approaches using fracture mechanics and damage mechanics. Traditionally, fatigue is divided into two stages; crack initiation and crack propagation. Crack initiation has been defined as the growth and coalescence of microcracks and crack propagation has been defined as the growth of macro-cracks (Suresh, 1991). Results from laboratory fatigue testing and full-scale accelerated trials indicate that the effective stiffness modulus of an asphaltic material can be reduced significantly under repeated loading without the presence of visible cracking. This indicates that damage is accumulating in the material thus reducing the effective volume able to carry the applied load (and hence reducing the effective stiffness modulus).

Continuum damage mechanics evolved in the 1960s as a way of representing the collective effect of crack-like defects on deterioration under mechanical loading (Lemaitre, 1996). Typically, the state of a material is characterised by a dimensionless scalar variable (known as damage) which ranges from 0 (undamaged) to 1 (fully damaged). This paper describes the application of continuum damage mechanics in a simple way to model fatigue of asphalt mixtures.

2 DAMAGE MECHANICS

From damage mechanics concepts, the internal damage to a body can be expressed in terms of a reduction in the effective area under uniaxial conditions (Kachanov, 1986), as follows:

(1)

where AD = area of flaws and A = area of the whole plane. It is clear that D is bounded by 0 (undamaged) and 1 (fully broken in two parts).

It was suggested by Lemaitre (1996) that the above equation should be re-expressed in terms of elastic (Young’s) modulus. For pavement engineering applications, the stiffness modulus can be used as follows:

(2)

where Se is effective stiffness modulus; and S is modulus of the intact material.

Assuming the internal damage gradually evolves as the number of loading cycles increases, the rate of damage growth per cycle could be expressed as a function of some critical parameters which represent the material characteristics and testing conditions, as follows:

(3)

where a is stress, ɛ is strain and T temperature.

3 UNIAXIAL FATIGUE TESTS

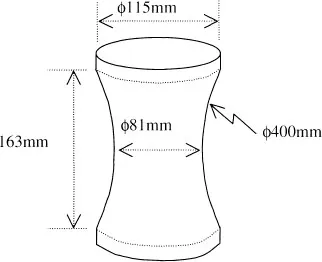

Data from uniaxial fatigue tests can be used to develop the function f in Equation 3 for one dimensional stress conditions. However, one of the most difficult aspects of the uniaxial fatigue test is the uncertainty of the failure position. A predictable failure position is necessary to measure accurate physical properties and to obtain reliable and stable test results. Therefore, a specimen with a necked central section has been developed. Figure 1 shows the details of the specimen geometry.

A mixture based on the specification for a 14 mm close graded wearing course Dense Bitumen Macadam (DBM) was selected for the test programme (BS 4987, 1988). Limestone aggregates and a 50 pen grade of bitumen were used in the mixture. The specimens were manufactured using a specially designed mould. A combination of static and vibratory compaction was used to achieve the required specimen density (air void content). After compaction the specimens were placed in the uniaxial testing machine (see Fig. 2) where they were subjected to sinusoidal loading (load control) at a frequency of 10 Hz.

Two Linear Variable Differential Transformers (LVDTs) were attached to the specimens (at diametrically opposite locations) to measure displacements over the central 60 mm of the necked section. The two LVDT readings were averaged and divided by the gauge length (60 mm) to provide a local strain measurement. A load cell was used to measure the applied force. The stress acting on the central section of the specimen was calculated and divided by the local strain to determine the stiffness modulus of the material. The test was continued until the specimen failed.

3.1 Investigation of Fatigue Behaviour

Figure 3 shows a typical set of stiffness modulus results plotted as a function of number of load a...