- 410 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Process Control Engineering

About this book

Process Control Engineering is a textbook for chemical, mechanical and electrical engineering students, providing the theoretic fundamentals of control systems, and highlighting modern control theory and practical aspects of industrial processes. The introductory nature of the text should appeal to undergraduate students, while later chapters on linear systems, optimal control, adaptive control and intelligent control are directed toward advanced students and practising engineers. The textbook has been extensively tested in both undergraduate and graduate courses at the University of Alberta.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Topic

Sciences physiquesSubtopic

Chimie industrielle et techniqueCHAPTER 1

INTRODUCTION

1.1. COMPOSITION OF CONTROL SYSTEMS

A control system is an interconnection of components that act together to satisfy a common control objective. The famous Watt steam engine is often used to mark the beginning of the industrial revolution in Great Britain. Invented in 1769, it was one of the earliest examples of a commercial device utilizing a built-in control system. Control systems currently play an important role in manufacturing, production, and, indeed, in human life generally.

Control engineering is concerned with the analysis and design of control systems.

A device, a plant or a system under control is called a process. More practically, a process is a set of material equipment along with the physical or chemical operations that take place within it.

Examples of feedback control systems

Feedback control is the most popular type of control system configuration. To understand the concept of feedback control, let us consider two illustrative examples.

The steering of a car can be considered as a control system. When one drives a car, the direction and the speed of the car must be controlled. The eyes of the driver observe the car’s direction and speed. This information is sent to the driver’s brain, where decisions are made. Decisions are executed by the arms and feet of the driver in turning the steering wheel and/or adjusting the pedals. If the car deviates from its desired direction or speed, the driver’s eyes sense this, and a corrective command is sent from the brain to the arms and feet, which then steer the car to reduce the error. There are two signal paths in the system: the command signals are sent from the brain to the arms and feet to control the car’s direction and speed, ‘measurements’ of which are fed back to the brain via the eyes.

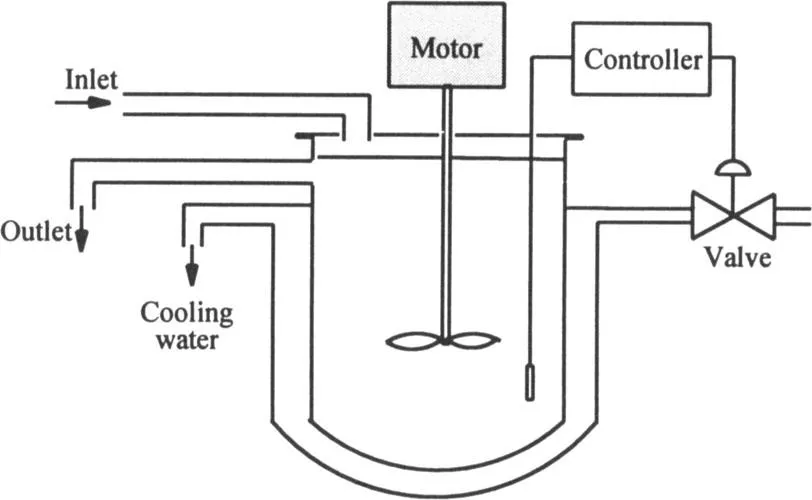

In contrast to the steering system example, an industrial process is usually controlled by automatic means, rather than by human operators. This is called process automation. Automation is very important for increasing productivity and ensuring high product quality. A simple reactor example is shown in Fig. 1.1.1. The temperature of the reactor is to be controlled to a prespecified value. Cooling water runs through the cooling jacket to remove heat generated by the reaction. The mixed raw material fed to the reactor may be of variable flow rate and temperature. The generated product is withdrawn at such a rate as to keep the amount of material in the reactor unchanged. The temperature of the reactor is measured by a thermocouple, and the measurement signal is transmitted to a comparator, where it is compared with the desired value. The difference between them is calculated, amplified, and used to adjust the control valve, thereby changing the flow rate of cooling water to the jacket. In this way, the temperature of the reactor may be kept at or near its target value.

Composition of systems

From the two examples above, the following hardware elements of a control system may be distinguished:

1. Process (Object): This represents the material equipment along with the physical and/or chemical operations which take place. The car and its physical operation compose the object of the steering system. The heat transfer between the reactor and cooling jacket constitutes the process in the second example.

2. Measuring instrument or sensor. Sensors are used to measure physical and/or chemical variables, and are the main sources of information about what is going on in the process. In the above examples, the driver’s eyes measure the direction and speed of the car, and the thermocouple measures the temperature of the reactor.

3. Controller: The controller receives information from the measuring devices and after calculation decides what action should be taken. In other words, it is a decision-maker which implements a control law.

Components | Definition | Steering system | Temperature control system |

Process (Object) | Material equipment along with physical and/or chemical operations | Car | Reactor and cooler |

Measuring instrument | Device which measures physical and/or chemical variables | Eyes | Thermocouple |

Controller | Control decision-maker | Brain | Comparator and amplifier |

Final control element | Device which manipulates physical or chemical variable of a process | Arms, feet | Valve |

In a steering system, the driver’s brain makes decisions and is therefore a controller. The comparator and the amplifier would be included in the controller of the second example.

4. Final control element: This device (also called an actuator or an executive component) manipulates a process variable. The flow control valve in the engineering example is the final control element. In the steering system, the driver’s arms and feet are final control elements.

From the viewpoint of control engineering, then, a system is composed of four basic parts: a process or object, measuring instrument(s), a controller and final control element(s). In practice, however, there may exist additional elements such as recording devices, measurement filters and protective gear.

The composition of a control system is summarized in Table 1.1.

General concepts and terminology

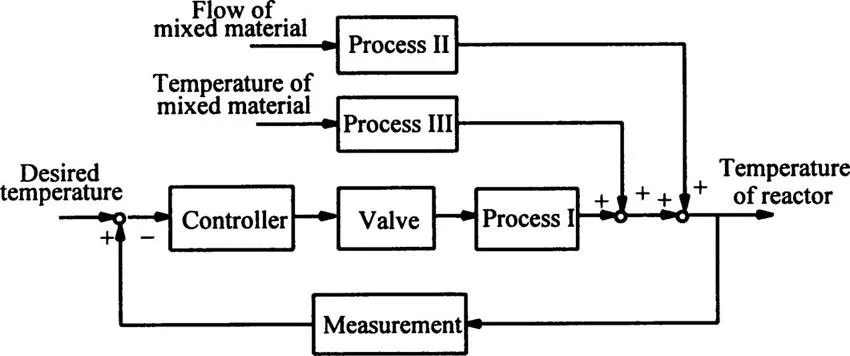

An intuitively appealing tool used to represent the configuration of a control system is the process block diagram. The block diagram is especially helpful in illustrating the relationship among the process variables. A functional block diagram of the temperature control system in the reactor example is shown in Fig. 1.1.2. Each block represents an element or combination of elements. (In Chapter 2, transfer functions describing the dynamic relationship between signals will replace the functional words in the blocks.) Each line represents a signal, and its arrowhead indicates the direction of signal flow. The circles indicate addition or subtraction of signals.

Before proceeding further, some general concepts and terminology should be introduced.

1. Manipulated variable. This is a variable in a control system that we can change in order to keep the system in a desired operating region. In the steering example, the angle of the steering whe...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Preface

- Chapter 1 Introduction

- Chapter 2 Mathematical Models and Transfer Functions

- Chapter 3 Time Domain Analysis and Design

- Chapter 4 Stability and Root Locus Technique

- Chapter 5 Frequency Domain Analysis and Design

- Chapter 6 Discrete Time System Analysis and Design

- Chapter 7 Process Control System Design

- Chapter 8 Advanced Control Systems

- Chapter 9 Linear State Space Analysis and Design

- Chapter 10 Optimal Control

- Chapter 11 System Identification and Adaptive Control

- Chapter 12 Intelligent Process Control

- Appendix

- References

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Process Control Engineering by A. Ramachandro. Rao,A.Ramachandro. Rao in PDF and/or ePUB format, as well as other popular books in Sciences physiques & Chimie industrielle et technique. We have over one million books available in our catalogue for you to explore.