- 300 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Dynamics of Machines with Variable Mass

About this book

Designed to be a complete and integrated text on the dynamic properties of machines, mechanisms, and rotors with variable mass, this book presents new results from investigations based on the general dynamics of systems with variable parameters. The book considers both weak and strong nonlinear vibrations of these systems, and chaotic phenomena are also discussed. The conservation laws and adiabatic invariants for systems with variable mass are formulated and the stability and instability conditions of motion are defined.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Dynamics of Machines with Variable Mass by L Cveticanin in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Mechanical Engineering. We have over one million books available in our catalogue for you to explore.

Information

1 Machines with Variable Mass

1.0 Introduction

In this chapter, various types of machines and mechanisms with mass variable elements are described, including features of their construction and operation. All of the machines mentioned are widely used in contemporary industry, transportation and measuring equipment. Rotors with variable mass are presented as a special group of mechanisms. They are the fundamental working elements of many machines in the process, cable, textile and paper industries, as well as in transportation, etc. The term “rotor with variable mass” will refer to all parts which are mounted on the rotating shaft and whose mass varies. The shaft, which is a fundamental element of the rotor, is designed to support machine parts rotating with it and to transmit bending moments, torques and longitudinal forces. In this chapter various models of rotors with variable mass are considered.

1.1 Mechanisms with Variable Mass

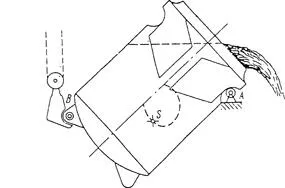

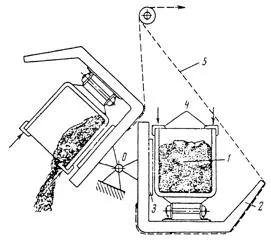

A pouring machine is plotted in Fig. 1.1.1. The hook of the crane grips the vessel at point B, and rotates it around A, pouring out the molten metal for continuous casting. The basic requirement for the equipment is that pouring of metal from the vessel has to be uniform, and it is regulated by the velocity of the hook. To estimate the process of lifting of the vessel and to give good control it is necessary to take into consideration the mass variation of the vessel, because it is the basic cause of uniform flow of metal. The position of the centre of mass of the vessel and metal varies. As a simplification this system can be considered as a rotating bar AB with variable mass and variable position of the centre of mass inside the element.

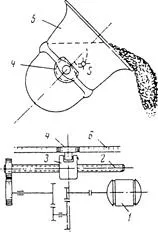

Let us consider some other mechanisms. The pouring of concrete from the vessel in Fig. 1.1.2 is achieved by a mechanism which contains an electric motor 1, which by a system of gears 4 and 6 and screws 2 and 3 transmits the motion to 4. As 4 is fixed to vessel 5 its motion about 6 turns the vessel 5. To analyze the elements and the process of vessel turning, the variable mass of the vessel has to be taken into account. Only in this way can the correct position of the turning axle and the torque for vessel rotating be obtained.

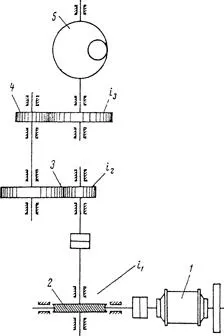

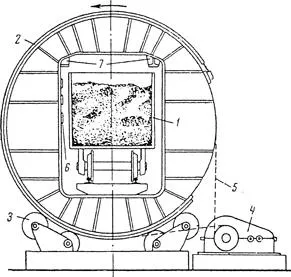

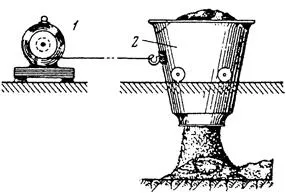

Converters are used for steel production. For melting the steel, the converter-vessel system is usually lifted and turned during the introduction of some additives and pouring out the finished steel. An electric motor 1 with a system of gear-wheels 2, 3 and 4 rotates the converter 5 (Fig. 1.1.3). Exact dynamic analysis taking into account the variation of the mass of metal in the converter is necessary for automatic control of the process. A system of a rotor type of wagon turner is shown in Fig. 1.1.4. The wagon with material 1 is in the rotor 2. The rotor rotates on cylinders 3 and is driven with a mechanism 4 and rope 5. The wagon is supported by positioners 6 and 7. By turning the wagon by an angle smaller than 180 degrees discharging is completed. The efficiency of this mechanism is very high. The mechanism for discharging a wagon which is widely used in the metallurgical industry for minerals is of the rotating type (Fig. 1.1.5). The wagon 1 is on the carrier 2, and is supported on the wall 3 and elements 4. The rope 5 is turning on the wheel and tips the carrier, discharging the material from the wagon. Torques are balanced with a system of counterweights. The mechanism productivity is high as the discharging is rapid. For dynamic analysis, the mass variation has to be taken into consideration.

A wagon 2 which moves laterally is shown in Fig. 1.1.6. It is driven by a motor 1. Another type of laterally moved wagon is shown in Fig. 1.1.7. Movement in one direction increases the mass and in the other it is decreased. The mechanism is a bar mechanism, and the motion may be reversible. In both mechanisms the mass varies.

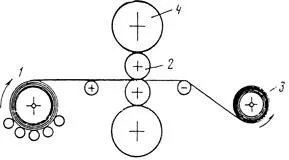

A rolling mill is shown in Fig. 1.1.8. Tin rolls down off the drum 1, travels through the rollers 2 and rolls up on the drum 3. The system is fixed by supporting rollers 4. Cold rolling is caused at a velocity 10 to 15 m/sec and more. During rolling up this tin and rolling it off the radius and the moment of inertia of the drum varies. One of the most important requirements is constant velocity of rolling up, and special automatic regulation and controls have to be introduced. To increase the efficiency of these machines, the dynamics of motion of this system with variable mass have to be analyzed.

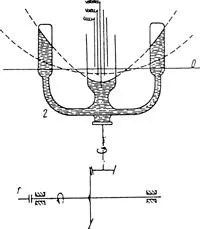

Another mechanism with variable moment of inertia is shown in Fig. 1.1.9. It is a centrifugal lifting basket regulator of motion. It contains shaft 1, system of gears, and a system of mercury filled tubes. The velocity of the shaft and of the tubes regulates the velocity of the basket. If the velocity of tubes is zero, the level of mercury in all tubes is the same. If the velocity increases, the mercury level attains a parabolic shape and the level in the middle tube decreases. If it gets to a very small level, the connection with the motor is broken and the shaft 1 slows down. If the velocity of basket motion is smaller than permitted, the regulator sets up the motor and transfers the motion to the shaft 1. As the position of the mercury depends on velocity, the moment of inertia varies, as a function of angular velocity, J(ω). To give the correct instructions for regulator dynamic behavior it is necessary to know the change of moment of inertia of the mechanism.

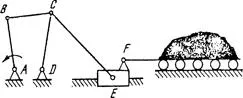

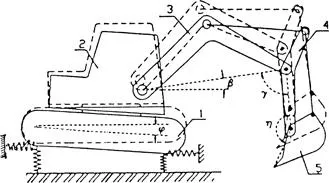

A simple planar model of an excavator is shown in Fig. 1.1.10. It consists of five rigid bodies: body 1 which is in contact with the ground, body 2 mounted on 1, body 3 connected to 2 by means of pivot, body 4 which is an excavator arm connected with 3 by means of a joint, and body 5 which is the excavator scoop and can rotate around the body 4. The excavator scoop has a varying mass. The operating movements can be realized by means of the jib 3, arm 4 or the scoop 5 movements.

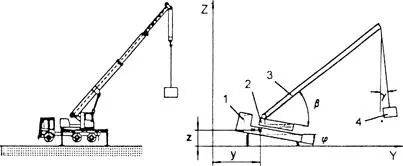

A crane represents a mechanism for load transportation. A typical sectional model of a crane (Fig. 1.1.11) consists of four rigid bodies: body 1 which is in elastic contact with the ground, body 2 mounted on 1, body 3 connected with 2 by means of joint and a component 4 connected with 3 by a flexible cord. Component 4 has a time variable mass, because it includes the load.

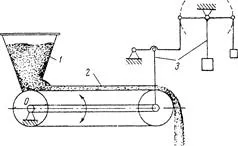

Variation of mass and its distribution along the elements of a mechanism have a significant influence on belt type automatic dosing devices. The aim of the mechanism is to achieve constant mass flow of material. The mechanism (Fig. 1.1.12) contains basket 1, belt conveyor 2 and bar mechanism 3. The bar mechanism is a sensitive element which directs the opening and shutting of the dosing device. The process of separating material from the conveyor may result in large vibrations around 0. These vibrations are undesirable and they are due to mass variation.

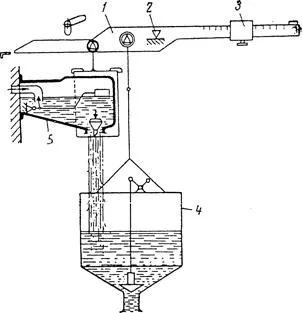

A mechanism for automatic measurement of liquid is shown in Fig. 1.1.13. It contains bar 1, which is pivoted at 2 and is under the influence of weight 3, and vessel 4 which is to be filled with liquid. The quantity of liquid is regulated by a special dosing device 5 which automatically regulates the liquid in the vessel by stopping the liquid getting in. It is connected to bar 1.

As can be seen, mechanisms with variable mass are widely used in various industrial fields: process, transportation, civil engineering, regulators etc. Most of them can be reduced to a simple dynamic model with one degree of freedom and variable parameters. Mass variation is a function of time (vibration mechanisms, dosing devices) or of position (mechanisms for vessels and wagon — turning, etc). For correct dynamic analysis of the mechanical system it is necessary to take this property of the system into consideration. Most of the mechanisms mentioned are systems with one degree of freedom and variable parameters.

1.2 Rotors with Variable Mass

The first step in the analysis of dynamic processes occurring in rotors is modeling. Due to the complexity of phenomena which occur during motion of the real system, it must be simplified by rejecting a number of less important factors and retaining those that influence the behavior of the system in an essential manner. In rotors mass variation is usually neglected as it is assumed that the mass variation is slow. Investigations on real rotors with variable mass show that this assumption is not correct.

The simplest model of a...

Table of contents

- Cover

- Half Title

- Series Page

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Introduction to the Series

- Preface

- 1 Machines with Variable Mass

- 2 General Principles of Dynamics of Systems with Variable Mass

- 3 Vibrations in Machines with Small Nonlinearities and with Parameters which Vary with Time

- 4 Vibrations of Machines with Time Variable Parameters and Strong Nonlinearity

- 5 Chaos in Systems with Time Variable Parameters

- 6 Conservation Laws and Adiabatic Invariants for Systems with Variable Mass

- 7 Stability of Motion of Machines with Variable Mass

- References

- Index