- English

- ePUB (mobile friendly)

- Available on iOS & Android

Process Control Basics

About this book

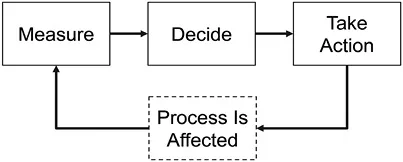

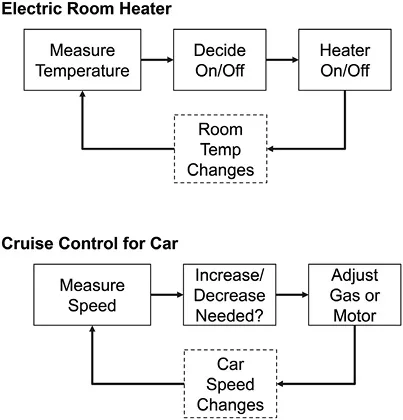

Process control is essential in modern manufacturing. The control system is the eyes, ears, and nervous system of the plant. It senses, decides, and directs the activities of the pumps, valves, motors, and other equipment. The control system handles many routine tasks, freeing up the operator to oversee the operation and handle new situations that arise. Without process control, it would be nearly impossible to efficiently produce commodities like pulp and paper, gasoline, plastic, and pharmaceuticals.Most people learn process control through hands-on plant experience, accompanied by a healthy dose of self-study. This is because textbooks generally address the mathematics of process dynamics and control, but often miss the practical aspects. This easy-to-read book fills the gap by focusing on practical real-world knowledge of process control systems, providing clear and concise examples, and providing practical advice for handling day-to-day maintenance and documentation. The author begins by discussing control terminology, principles, and applications, the information one needs to form a basic understanding of process control. He then explains the differences between discrete, continuous, and batch control, as well as the different control systems, programming languages, and documentation needed for each. To complete the foundation, the author addresses the management of control systems including discussions about maintenance, change management, communications, and documentation. Finally, one chapter introduces advanced control topics such as advanced regulatory control, multivariable control, and neural networks.Whether you are a student of process control, a technician or engineer expanding their skills, or someone in operations, maintenance, sales, support, or management who wants to develop a basic understanding of process control, this book is for you.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Contents

- Acknowledgments

- Preface

- About the Author

- Chapter 1: What Is Process Control?

- Chapter 2: Basic Measurements

- Chapter 3: Control System Basics

- Chapter 4: Communications

- Chapter 5: Final Control Elements

- Chapter 6: Continuous Control

- Chapter 7: Logic Control

- Chapter 8: Control System Documentation

- Chapter 9: Practical Considerations

- Chapter 10: Advanced Sensors and Analyzers

- Chapter 11: Beyond the Basics of Process Control

- Abbreviations/Acronyms

- Bibliography

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app