Fabric Manufacturing Technology

Weaving and Knitting

- 176 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

Fabric Manufacturing Technology: Weaving and Knitting gives the reader a brief idea about the processes involved in fabric formation methods, namely weaving and knitting. It includes various mechanisms involved beginning with primitive handlooms to the latest shuttleless looms, and from hand knitting to the ultra-modern electronic knitting machines. Various design aspects involved in producing the different types of woven and knitted fabrics are dealt with comprehensively. The techno-economics of the latest weaving and knitting machines have been described, including applications of woven and knitted fabrics in the medical field, automotive engineering, aeronautical engineering, protective clothing, and more.

Features

-

- Covers the principles involved in the numerous operations of weaving and knitting processes

-

- Gives a basic understanding of fabric production, quality control and production

-

- Provides a summary of the fabric manufacturing process of weaving, knitting and nonwovens

-

- Discusses principles of mechanisms, as well as details of present-day machinery, with illustrations

-

- Explores the latest developments in knitting production by whole garment (Shima Seiki) and Knit and Wear (Stoll), CAD/CAM production and simulation of woven fabrics

This book is aimed at senior undergraduate students in textile processing and fabric manufacturing.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1 Introduction

1.1 CLOTHING

1.2 RAW MATERIALS

The fibres used for textile applications are:Natural fibres: Cotton, linen, jute, hemp, ramie, wool and silkSynthetic fibres: Polyester, nylon, rayon, spandex, olefin, aramid, acrylic, carbon and glass

1.3 SPINNING

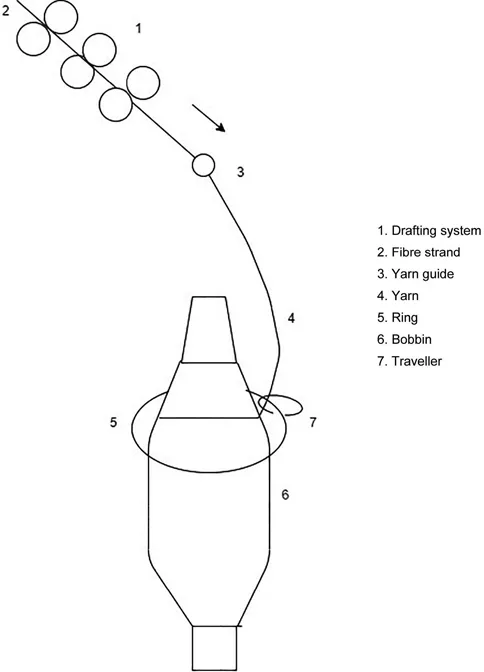

1.3.1 RING SPINNING

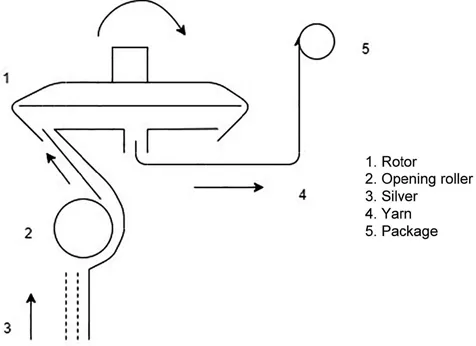

1.3.2 OPEN-END SPINNING

1.4 YARN NUMBERING SYSTEM

-

Indirect systemThis is the traditional system that originated from England. In this system length per unit weight is specified. The number of hanks (840 yards) present in 1 pound of yarn is defined as the yarn number or yarn count. Suppose in a particular yarn if 10 hanks (8,400 yards) weighs 1 pound, then the yarn count of that yarn will be 10s Ne. (“Ne” refers to English count.) In the indirect system, the higher the yarn number or count, the finer will be the yarn. For example, 40s Ne yarn will be finer than 20s Ne yarn.

-

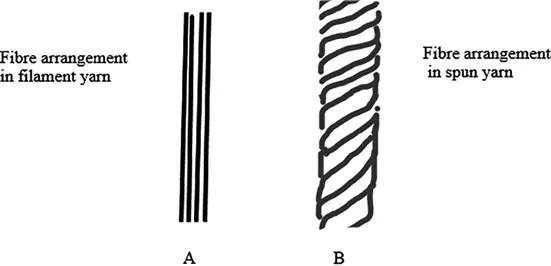

Direct systemIn the direct system, the weight per unit length is specified. The weight in grams per 1000 metres of yarn is defined as the yarn count and this count is called tex. For example if 1000 metres of yarn weighs 40 grams, then the yarn count is 40tex. In the direct system, the higher the yarn count number, the courser will be the yarn. For numbering filaments and fibres, another term is used: denier. Denier is defined as the weight in grams of 9000 metres of filament yarn.

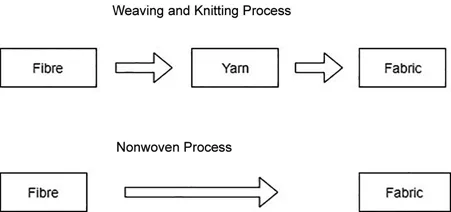

2 Fabric Formation Methods

- Weaving,

- Knitting and

- Nonwoven.

2.1 WEAVING

Table of contents

- Cover

- Half Title

- Title

- Copyright

- Dedication

- Contents

- Preface

- Authors

- Chapter 1 Introduction

- Chapter 2 Fabric Formation Methods

- Weaving

- Knitting

- Nonwoven

- Index