- 216 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

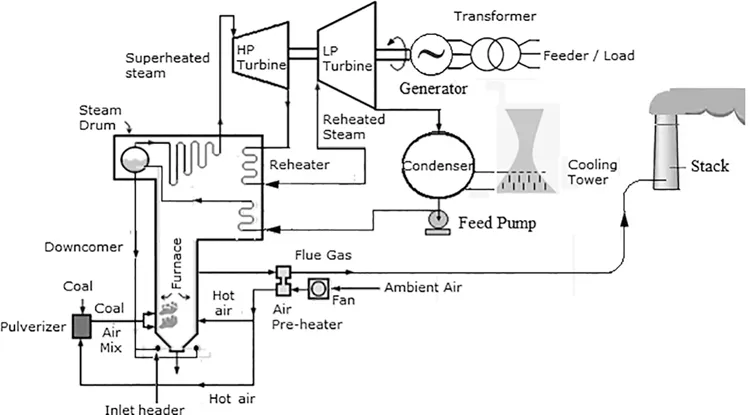

Industrial Power Systems: Evolutionary Aspects provides evolutionary and integrated aspects of industrial power systems including review of development of modern power systems from DC to microgrid. Generation options of thermal and hydro power including nuclear and power from renewables are discussed along with concepts for single-line diagram, overhead transmission lines, concepts of corona, sag, overhead insulators and over voltage protective devices. Subsequent chapters cover analysis of power systems and power system protection with basic concept of power system planning and economic operations.

Features:

- Covers the fundamentals of power systems, including its design, analysis, market structure and economic operations

- Discusses performance of transmission lines with associated parameters, determination of performance and load flow analysis

- Reviews residual generation/load imbalance as handled by the automatic generation control (AGC)

- Includes different advanced technologies including HTLS overhead conductor, XLPE cable, vacuum/SF6 circuit breaker, solid state relays, among others

- Explores practical aspects required for field level work such as installation of cable network for power distribution purposes, types of earthing and tariff mechanism

This book will be of interest to graduate students, researchers and professionals in power engineering, load flow and power systems protection.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Introduction

1.1 Evolution of Electrical Power System

1.2 Thermal Power Plant

- Water Preparation – The total feed water in a thermal power plant consists of re-circulated condensate water and purified makeup water to replace water lost through sampling systems, steam losses, evaporation from cooling and blow-down. Water softeners and ion exchange demineralizers using membrane technology to remove dissolved impurities and produce ultra-high-pure makeup water that it coincidentally becomes an electrical insulator.

- Coal Preparation – Coal preparation is the removal of undesirable material from the Run-of-Mine coal by employing separation processes. Coal from the coal storage area is first crushed into small pieces and then conveyed to the coal feed hoppers at the boilers. Before entering the boiler, the coal is pulverized into a very fine powder, so that coal will undergo complete combustion during combustion process. Dryers are used in order to remove the excess moisture from coal that is mainly wetted during transport. The presence of moisture will result in fall of efficiency due to incomplete combustion and also result in CO emission. Magnetic separators are used to remove tramp iron pieces or separate iron particles from coal. Crushers are used for breaking coal into pieces of required feed size, which in pulverizing mill is 30 mm or below. The crushing is done in ring crusher and the hammer mill. Pulverizing of coal is done in either Ball and Tube Mill Pulverizer or Ring and Ball Pulverizer. Breaking a given mass of coal into smaller pieces in a pulverizer exposes more surface area for combustion, which allows faster combustion as more coal surface is exposed to heat and oxygen. This reduces the excess air required to ensure complete combustion and the required fan power also. A wide variety of low-grade coal can be burnt more easily when the coal is pulverized. Pulverized coal gives faster response to load changes as the rate of combustion can be controlled easily and immediately. Further, pulverized fuel systems are nowadays universally used for large capacity plants and use low-cost (low grade) fuel as it gives high thermal efficiency and better control as per the load demand.

- Boiler and Auxiliaries – Boilers may be of two types. (i) Fire Tube type where hot gases pass through the tubes and boiler feed water in the shell side is converted into steam and is generally used for relatively small steam capacities up to 12,000 kg/hour and low to medium steam pressures up to 18 kg/cm2. Fire tube boilers are available for operation with oil, gas or solid fuels. (ii) Water Tube Boiler where boiler feed water flows through the tubes and enters the boiler drum. The circulated water is heated by the combustion gases (capacity range 4,500–120,000 kg/hour of steam) and converted into steam at the vapor space in the drum. These boilers are selected when the steam demand and steam pressure requirements are high as 125 kg/cm2. Further boilers may be classified as: (i) Fluidized Bed Combustion type that has the advantages of high efficiency. Reduction in boiler size can be achieved due to high heat transfer rate over a small heat transfer area immersed in the bed with reduction in pollution control as SO2 formation is greatly minimized by the addition of limestone or dolomite. Fluidized bed boilers have a wide capacity range of − 0.5 to over 100 T/hour. (ii) Atmospheric Fluidized Bed Combustion type, where atmospheric air, which acts as both the fluidization air and combustion air, is delivered at a pressure and flows through the bed after being preheated by the exhaust flue gases. (iii) Combined Fluidized Bed Combustion type, where coal is crushed to a size of 6–12 mm depending on the rank of coal and type of fuel feed fed into the combustion chamber. A Combined Fluidized Bed Combustion could be a good choice if the capacity of boiler is large to medium.

- In the steam-generating process, the furnace or burner systems provide controlled, efficient conversion of the chemical energy to heat energy, which in turn is transferred to the heat-absorbing surfaces of the steam generator. To do this, the firing system introduces fuel and air for combustion, mixes these reactants, ignites the combustible mixture and distributes the flame envelope and the products of combustion. Furnaces are of two types: (i) Grate-fired furnace is suitable for burning solid fuels like coal. Grate is provided for supporting the solid fuel and is so designed that it can also allow air to admit in the solid fuel for combustion. (ii) Fuel bed furnace is suitable for burning pulverized coal. Fluidization is a method of mixing fuel and air in a specific proportion, for obtaining combustion. A fluidized bed may be defined as the bed of solid particles behaving as a fluid. It operates on the principle that when an evenly distributed air is passed upward through a finely divided bed of solid particles at low velocity, the particles remain undisturbed, but if the velocity of air flow is steadily increased, a stage is reached when the individual particles are suspended in the air stream. If the air velocity is further increased, the bed becomes highly turbulent and rapid mixing of particles occurs which appears like formation of bubbles in a boiling liquid and thus the process of combustion as a result is known as fluidized bed combustion.

Table of contents

- Cover

- Half Title Page

- Series Page

- Title Page

- Copyright Page

- Dedication Page

- Table of Contents

- Preface

- Authors

- Chapter 1 Introduction

- Chapter 2 Transmission and Distribution Systems

- Chapter 3 Overhead Transmission Line Constants

- Chapter 4 Corona and Sag

- Chapter 5 Cable

- Chapter 6 Characteristics and Performance of Transmission Line

- Chapter 7 Insulators for Overhead Lines

- Chapter 8 Overvoltages and Insulation Requirements

- Chapter 9 Electrical Fault Analysis

- Chapter 10 Load Flow Analysis

- Chapter 11 Stability Analysis

- Chapter 12 Fuses and Circuit Breakers

- Chapter 13 Power System Protection

- Chapter 14 DC Transmission

- Chapter 15 Electrical Power Distribution Substation

- Chapter 16 Power System Structure

- Chapter 17 Economic Operation of Energy Generating Systems

- Chapter 18 Automatic Generation and Control

- Chapter 19 Compensation in Power System

- Questions & Answers

- References

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app