![]()

ARMATURE WINDING

AND

MOTOR REPAIR

CHAPTER I

DIRECT-CURRENT WINDINGS

The essential physical differences between a complete direct-current and a complete alternating-current armature winding is that the former is wound on the rotating member of the machine while the latter is wound on the stationary member and that the direct-current winding requires a commutator while the alternating-current winding does not. However, since the practical make-up and construction of windings will be discussed later for particular types of direct and alternating-current machines, the general theory of armature windings will likewise be taken up first for direct-current and then for alternating-current machines (see Chapter II).

Action of a Commutator.—The emf and current produced in each armature conductor of a direct-current generator is alternating in character. It is the function of the commutator to deliver from the armature winding an electromotive force and current that is unidirectional, that is, such that one terminal will be always of positive polarity and the other of negative polarity. The commutator and its brushes accomplish this by being connected in series between the generator leads and the armature windings so as to reverse (in effect) the connections of the armature coils (connected to the commutator bars) with respect to the machine leads every time the emf and current induced in these coils reverse upon moving out of the influence of one pole into the field of the next adjacent pole. The alternating emf and current generated in the armature winding is thus rectified or commutated into a unidirectional emf and current.

In the case of an alternating-current generator no such rectifying of induced emf and current is necessary so that the coils or elements making up the armature winding can be connected directly together with the resulting terminals of the winding becoming the terminals of the machine.

Types of D.-C. Armature Windings.—In general, armature windings are either of the open circuit or the closed circuit type. The latter is used in all modern direct-current machines, while alternating-current machines may have either open or closed windings. In the closed circuit winding of the direct-current machine the end joins up with the beginning or re-enters itself with the commutator tapped to the winding at equally distant points. In the case of open circuit winding of an alternating-current generator wound on the revolving member, the ends terminate in collector rings and the winding is thus open until closed by the brushes of the external circuit. When the winding is on the stator of an alternating-current machine the ends are joined through the load circuit. The following classification of closed circuit or direct-current windings may be made:

Direct-current windings (closed circuit).

1. Lap—multiple or parallel.

(a) Single lap.

(b) Multiplex lap.

2. Wave—series or two-circuit.

(a) Single wave.

(b) Multiplex wave or series-parallel windings.

Winding Parts and Terms.—In formulas for armature windings and in laying out a repair job, certain terms are used which refer to parts of the armature winding, the armature core and details of the arrangement of the former in the slots on the surface of the latter. In what follows these terms are explained. In most cases they are used alike both in windings for direct-current and for alternating-current machines.

Armature Conductor or Inductor.—That part of a wire which lies in an armature slot and cuts the magnetic lines of force or field flux as the armature rotates, is called an armature conductor or an inductor.

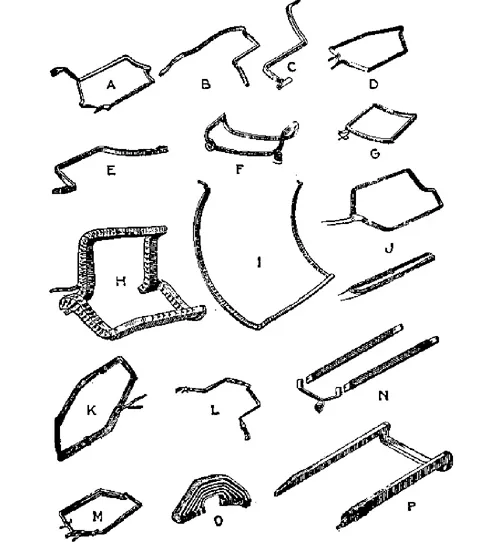

FIG. 1.—Different types of coils used in armature windings.

(A) One-piece series diamond strap coil. Leads at end of straight part. (B) One-piece series diamond coil. Leads at end of straight part. (C) Two-piece series diamond coil. (D) One-piece multiple diamond coil. Leads at point of diamond. (E) Two-piece multiple diamond coil. (F) Concentric coil bent down at both ends. (G) Concentric coil, straight. (H) One-piece wire wound involute coil. Leads at point of involute. (I) Two-piece involute coil. Leads, at point of involute. (J) Threaded-in type diamond coil. Leads at point of diamond before and after pulling. (K) Basket coil. (L) Same as B of threaded-in type. (M) same as D of threaded-in type. (N) Bar and involute end connector. (O) Group of concentric end connectors. (P) Concentric shoved through type coil bent down on one end.

Winding Element or Section.—That part of an armature winding which is connected between two commutator bars is called a winding element. In its simplest form a winding element consists of a coil of one turn of wire or two conductors. An element therefore must have at least two conductors but may consist of more than one turn of wire or even number of conductors.

Armature Coil.—When a winding element consists of more than one turn of wire or two conductors, it is usually known as a coil and the winding is a coil winding as distinguished from a bar winding, where the conductors in the armature slots are copper bars.

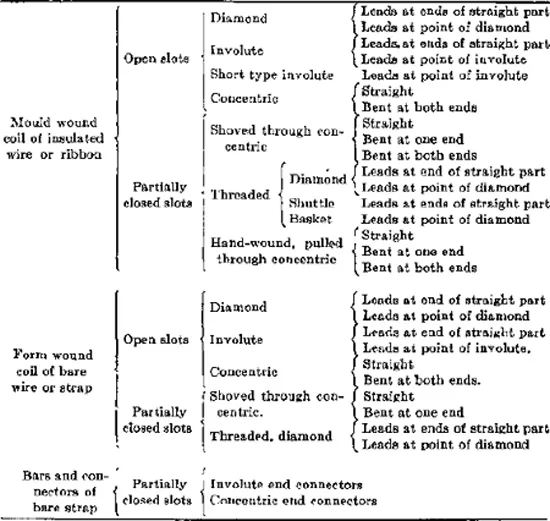

From a mechanical standpoint an armature winding consists of a number of coils connected to a commutator in the case of a direct-current machine or connected together in the case of an alternating-current machine to form a series or group. Each coil may be made up of one turn of wire with each side forming one armature conductor or inductor, or a coil may be made up of several turns of wire or of copper strips. A classification of the different types and uses of armature coils which has been made by R. A. Smart (Electric Journal, Vol. VII, No. 6) is given in the accompanying table.

The so-called form-wound, diamond coils mentioned in the table are formed and completely insulated before being assembled on the armature. They can only be used in open slots Concerning the advantages of diamond coils, involute coils and concentric coils, Mr. Smart has the following to say: “The great advantage of diamond coils is the easy and simple manner in which they can be manufactured, especially in large quantities, which makes them well adapted for standard machines. Since all the coils used on one machine are of the same size and shape, only one winding mould over which to form them is necessary. Moreover, the number of spare parts which must be kept on hand for repairing is reduced and repairs can be made easily and quickly. From the electrical point of view, the diamond type of winding possesses the advantage of being absolutely symmetrical. Hence there is no tendency for unbalancing of voltages due to differences of self-induction; and in closed windings there is no tendency to produce internal circulating currents.”

CLASSIFICATION OF ARMATURE COILS ACCORDING TO SLOTS IN WHICH THEY ARE USED, THEIR FORM AND TRADE NAMES AS EMPLOYED IN BOTH DIRECT- AND ALTERNATING-CURRENT-WINDINGS

Involute Coils.—“Involute coils share the advantages of the diamond coils in that all are of a standard size and shape. They also require less space for end connection than any other form of coil. They are, however, difficult to insulate properly on account of the larger number of bends and are difficult to assemble in position in the armature. For this reason their use is restricted. The bar typo of coil with involute end connectors is easy to insulate and assemble and can be readily repaired. Their principal use is for direct-current and industrial motors where end space must be reduced to a minimum.”

Concentric Coils.—“Concentric coils can be used on any kind of slot. They can be hand-wound, machine-wound, or ‘shoved through’ (a combination of the other two methods), as best suited. The shape of coils is simple, hence they are easy to wind either on a mould or by hand. They can be adequately insulated, and can be securely braced with simple and reliable coil support. However, the coils belonging to the same group are of different size, and the coils in different groups, except on single-phase machines, are bent in at leas...