Applications of Polymer Nanofibers

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Applications of Polymer Nanofibers

About this book

APPLICATIONS OF POLYMER NANOFIBERS

Explore a comprehensive review of the practical experimental and technological details of polymer nanofibers with a leading new resource

Applications of Polymer Nanofibers delivers a complete introduction to the basic science of polymer nanofibers as well as a review of their diverse applications. The book assesses their potential for commercialization and presents contributions from leading experts emphasizing their practical and technological details. New and up to date research findings are presented throughout the book in areas including filters, fabric, energy, fuel cells, batteries, sensors, biomedicine, drug delivery, tissue engineering, and wound dressings.

The book also presents a fulsome analysis of the technology of electrospinning, the most convenient and scalable technique for nanofiber production. It also provides readers with practical information on relevant surface modification techniques. Applications of Polymer Nanofibers effectively balances theoretical background with practical applications of the technology, including insights into polymer nanofiber materials that will be useful for advanced students and researchers. Students, researchers, and industry professionals will also enjoy the inclusion of:

- A thorough introduction to electrospinning parameters and resulting nanofiber characteristics, including theoretical and practical considerations

- An exploration of textile applications of nanofibers, like protective clothing, filter fabrics, wearable devices, functional fabrics, and biomedical textiles

- A review of nanofiber mats as high-efficiency filters, including filtration developments, filters made with nanofibers, and the future outlook for nanofiber filters

- A treatment of nanofiber-based chemical sensors, including sensor materials, approaches to nanofiber sensor design, and gravimetric nanofiber sensors

Perfect for researchers and graduate students studying polymer science and engineering, chemical engineering, materials science, and nanotechnology. Applications of Polymer Nanofibers will also earn a place in the libraries of industrial researchers concerned with electrospinning, air filtration, fabrics, drug delivery, catalysis, and biomedicine.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Electrospinning Parameters and Resulting Nanofiber Characteristics : Theoretical to Practical Considerations

1.1 Electrospinning Overview

1.2 Effect of Process Parameters

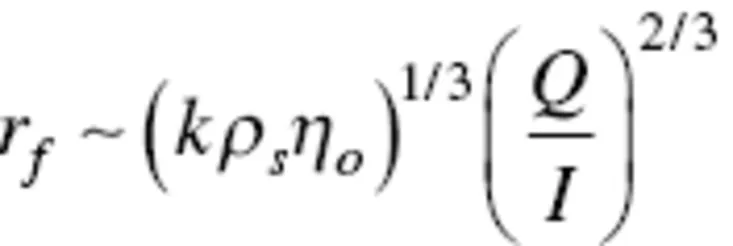

1.2.1 Theoretical Analysis

Table of contents

- Cover

- Table of Contents

- Title Page

- Copyright Page

- Dedication Page

- List of Contributors

- Prefacepreface

- 1 Electrospinning Parameters and Resulting Nanofiber Characteristics

- 2 Textile Applications of Nanofibers

- 3 Nanofiber Mats as High‐Efficiency Filters

- 4 Nanofiber‐Based Chemical Sensors

- 5 Nanofibers in Energy Applications

- 6 Electrospun Nanofibers for Drug Delivery Applications

- 7 Interfacing Electrospun Nanofibers with Microorganisms: Applications from Killing to Repelling to Delivering Living Microbes

- 8 Advances in Functionalizing the Interior and Exterior of Polymer Nanofibers

- 9 Nanofiber Aerogels

- 10 Micro and Nanofibers

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app