- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Cloud Systems in Supply Chains

About this book

Cloud Systems in Supply Chains explores the risks that could face supply chain firms if their implementation of cloud systems is not carefully managed or if not appropriately selected and supported. This volume aids supply chain firms in ensuring that their cloud system activities are positioned to assist and sustain their competitive advantages.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Could Cloud Systems Drive

Sustainable Competitive Advantages

in Supply–Demand Chains?

Fawzy Soliman

1.1 Introduction

According to Soliman (2013), competition in the 21st century is between different supply chains rather than between different companies. Supply Chain Management (SCM) as a theory of modern corporate management considers supply chains (SC) as a set of activities that move goods or services along the chain to the point of consumption. According to Quizlet (2013), retailing is the last step in a supply chain, and is responsible for “matching the individual demands of the consumer with quantities of products supplied by huge range of manufacturers.”

Plazibat and Brajevic (2009) have argued that “demand in retailing has its inherent characteristics, such as high substitutability of similar products, variety, quantity range, etc. Demand Chain Management (DCM) is an indispensable management tool.” This implies that customers at the final point of contact are the point at which information about their actual needs is obtained.

1.2 The concept of Supply Chain Management (SCM)

Earlier research viewed the supply chain as an internal management arrangement in manufacturing enterprises in which the enterprises purchased raw materials and components from external suppliers, and then delivered to retailers and users through a conversion of production and sales. This implies that SCM is concerned with the internal operation and utilization of the enterprise’s own resources. However, recent research on Delicacy Management, Supplier Performance Assessment and User Satisfaction indicates that the concept of the supply chain is closely linked with purchase and supply management (Palmberg, 2005).

Mentzer et al. (2001) considered the supply chain to be:

the systemic, strategic coordination of the traditional business functions and the tactics across these business functions within a particular company and across businesses within the supply chain, for the purposes of improving the long-term performance of the individual companies and the supply chain as a whole.

The SCM concept has wider implications to other enterprises and environment external to the supply chain.

Heikkilä (2002) pointed out that “the concept of SCM should be expanded from the perspective of operation from individual economic entity or companies to the whole supply chain.” Actually, SCM is a series of operations and coordination from material suppliers through to final users. The objective of SCM is to improve the entire process rather than specific parts of it. The role of cloud systems is therefore is an enabler to facilitate the integration between those entities.

Vollmann and Cordon (1998) suggested the concept of SCM could be replaced by DCM, thought highly of the market and designed specific chains to meet the demands of the market. According to Dell and Fredman (2006), “consumers are the real director of supply chain.” Scholars and practitioners have realized the importance of managing customers’ demands, not just supplies.

1.3 The concept of Demand Chain Management (DCM)

Demand Chain Management (DCM) has been defined by Selen and Soliman (2002) as “extending the view of operations from a single business unit or a company to the whole chain.” DCM is a set of practices aimed at managing and coordinating the whole demand chain, starting from the end customer and working backward to raw material suppliers (Selen and Soliman, 2002). According to the definition by Gartner Research (2013),

DCM is not only the business strategy corporations’ take to keep synchronization of clients, channels, and the partners by various kinds of means but also an integrated strategy which is closely related to the demand chain.

Specifically, DCM covers areas such as Customer Relationship Management, Demand Management, Sales Management, Inventory Control, Event Management and so on. These activities are best handled by cloud systems that integrate the most important three components, namely ERP, CRM and e-commerce (Soliman, 2012). Excellent DCM should combine all the decision-making, planning and implementation of these areas toward common objectives. Most cloud systems are designed to facilitate this level of decision-making in supply/demand chains.

According to Brace (1989), the focus of Demand Chain Management is customer-centric. Brace (1989) argued that the concept of DCM applies to the whole of the manufacturing and distribution processes. Brace also described DCM as a sequence of events designed to serve the ultimate consumer.

The rapid uptake of technology and in particular the Internet has resulted in the continual evolution of the DCM concept. The main stimulus behind this has been the shift in power away from the supplier and toward the customer (Soliman and Youssef, 2001).

Lalonde (1998) outlined five critical success factors for the Supply–Demand Chain Management relationship as follows:

(1) information sharing;

(2) sharing the common responsibility of risks and benefits;

(3) extensive contacts between all entities of the chains;

(4) effective cross-functional management flow;

(5) the existence of cooperation strategies, policies and procedures.

Lalonde (1998) also pointed out that if any one of the five critical factors are unsatisfactorily executed, the Supply–Demand Chain Management relationship could collapse. Lee (2004) argued that “efficient and cost-effective supply chains often become uncompetitive because they don’t adapt to changes in the structures of markets.” Frohlich and Westbrook (2002) indicated the most respected and popular concerns are those that use DCM to link customers and suppliers together into an overall network.

Ellis (1999) pointed to the impact of the relationship between the measurement of the effectiveness of SCM and DCM and the market value (company value) as a function of expected cash flow. Walters (2006) agreed that “profit is a matter of starting perspective but cash is a question of fact and that the performance evaluation of DCM and SCM could impact on the firm’s cash flow as a measure of the success of the supply chain firm.”

Retailing in particular has experienced a shift from “competition between companies” to “competition between supply chains.” The major assignment of SCM is to match more and more customers’ demands with products and services. However, the retailing industry has its own distinguishing feature, such as the fact that there is no open process of raw materials purchase, as big retailers always have their own distribution centers, they contact consumers direct and they cooperate and communicate with producers to form a closed chain. These important functions are best performed with the use of an appropriate cloud system.

1.4 The relationship between SCM and DCM

SCM incorporates business integration into the concept with emphasis on the controlling function of the supply chain. The integration not only applies to the logistics of raw materials delivered from suppliers to final users but also to the information flow communicated from market feedback to supply chain partners. Business integration assists in managing the use of information to achieve the optimum logistics through a set of procedures of internal and external distribution (Van Landeghem and Vanmaele, 2002). Hence the use of cloud systems enhances the effectiveness of SCM.

DCM concerns the management and coordination of the whole supply chain in accordance with sequential movements from supplier to terminal customer and back to suppliers. According to Lummus and Vokurka (1999), “It is driven by the final users, which means products and services are pulled not pushed by demands to make a smooth operation line.” However, Langabeer and Rose (2001) viewed DCM as a separate concept from SCM. They defined DCM as a “complicated network of business processes to help enterprises understand, manage and ultimately create consumer demands.”

According to Treville et al. (2004), “From the perspective of supply chain, demand chain can be regarded as a supply chain which is laying more stress on the customers’ actual demands rather than giving much attention to making sure the effective supply.” Frohlich and Wesbrook (2002) found that “a demand chain was a supply chain practice of management and coordination from the terminal to the upstream suppliers.” Similarly, SCM/DCM could result in further stress on the strategic coordination among the various enterprise departments, thus leading to integration of physical flow and information flow. However, in this process, DCM extends SCM to the field of rapid response and coping strategies to customers’ needs.

Van Landeghem and Vanmaele (2002) pointed out that “marketing, sales and service of value chain are considered more important in DCM than in SCM.” DCM seeks to obtain more information about customers or potential consumers such as changes in preference, the product lifecycle and the impact of promotion. In SCM, by contrast, market demand is deemed as an exogenous variable using some simple mathematical method, DCM observes information fed back from the market and every movement of the target market, taking actions toward the possible opportunity. There is no doubt that the extension of DCM is more helpful to achieve the “win/win” of better efficiency of the supply chain and customer satisfaction.

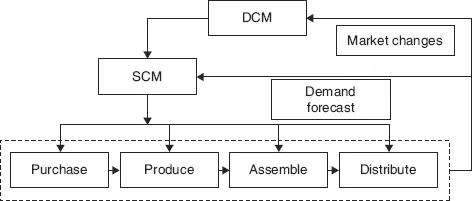

According to Kuglin (1998), “DCM is a customer-centric SCM … its core objective is to satisfy the customer’s actual demand.” A diagrammatic illustration of the relationship between DCM and SCN is shown in Figure 1.1.

A comparison between DCM and SCM is shown in Table 1.1.

Figure 1.1 The relationship between DCM and SCM

Source: After Van Landeghem and Vanmaele, 2002.

Table 1.1 The differences between DCM and SCM

Attributes | SCM | DCM |

Core | Coordination between big manufacturers and retailers | Meet the actual demand of customers |

Strategic goal | An effective supply chain | Effectiveness, customer satisfaction, profits and validity |

Operation mode | “Push” management starting from costs | “Pull” management starting from demand |

Cooperation base | Information sharing and risk co-burdening along the supply chain | Sharing information along the supply chain to achieve cooperation in demand |

Operation effectiveness | Stress on effectiveness while neglecting validity | Emphasizing actual demands with higher customer satisfaction |

Information management | Somewhat important | Very important |

1.5 Strengths of DCM

From the analysis above, it appears that DCM is an extension of SCM. It is not only a process of convergence of all aspects of the supply chain but also a process to maximize the meeting of customers’ demands. DCM has transformed the interaction be...

Table of contents

- Cover

- Halftitle

- Title

- Copyright

- Contents

- List of Figures and Tables

- Notes on Contributors

- Introduction: Cloud Systems in Demand–Supply Chains

- 1 Could Cloud Systems Drive Sustainable Competitive Advantages in Supply–Demand Chains?

- 2 Application of a Cloud-Based Supply Chain Management System to Achieve Mass Customization: Best Practices from the Automotive Industry

- 3 Applying Cloud Computing in Supply Chain Management in the Middle East

- 4 Service-Oriented Architecture, Agile, Lean and Component-Based Software Engineering: Future Solutions for Cloud Computing

- 5 Strategies for Deployment of Cloud Systems in Supply Chain Firms

- 6 SaaS Empowered Innovative On-Demand Software Applications: Potential and Challenges of the Cloud

- 7 Evaluating Cloud System Providers: Models, Methods and Applications

- 8 Macroprudential Regulation and Bank Performance: Evidence from India

- 9 Changing Needs in Supply Chain Management: Curriculum Design to Reflect Changing Needs

- 10 Banking and Financial Sector in the Cloud: Knowledge, Quality and Innovation Management

- 11 An Overview of Cloud Systems and Supply Chains in Jordan

- 12 Investigating the Role of Knowledge Gaps in Enhancing Quality in Cloud Environments

- 13 Does the Cloud System Drive Supply Chain Sustainability?

- 14 Role of Knowledge, Learning and Innovation in Enhancing Sustainability of Cloud-based Supply Chains

- 15 Collaborative Supply Chain Inventory Performance Analysis Using Google Spreadsheet

- 16 Cloud-based Data Storage for Data Management in the Virtual Factory

- 17 Online Supply Chain Management and Business Ethics

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Cloud Systems in Supply Chains by Fawzy Soliman in PDF and/or ePUB format, as well as other popular books in Business & Business Strategy. We have over one million books available in our catalogue for you to explore.