- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Competitive Supply Chains uniquely focuses on European and Asian companies, which have found innovative ways of orchestrating effective systems. This new edition builds upon the ideas explored by the author in Competitive Supply Chains (2007), featuring new content and analysis.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Working Definitions

1.1 Motivation

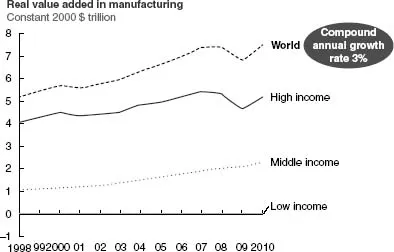

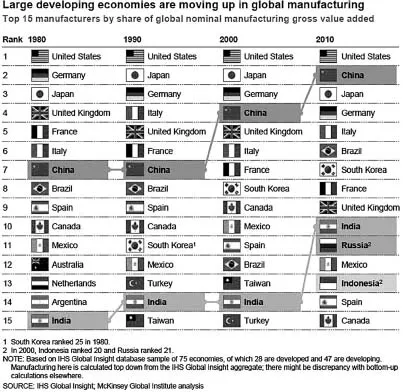

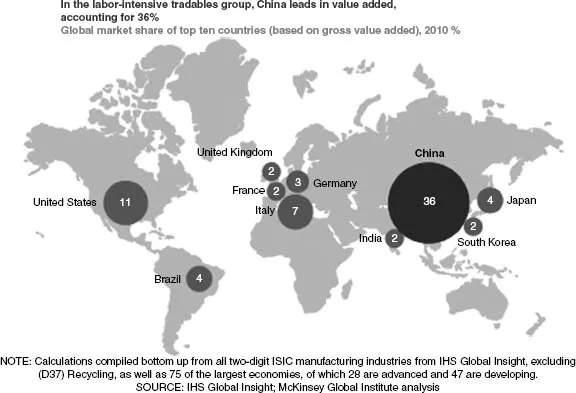

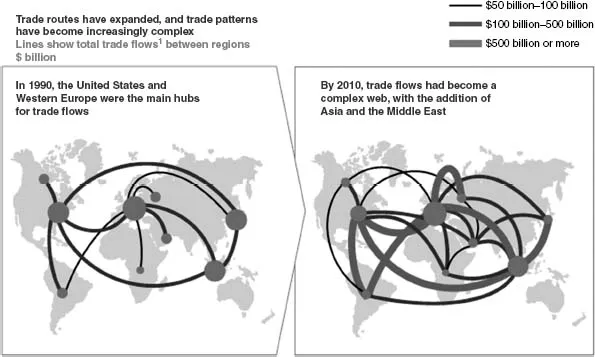

For nearly three centuries, manufacturing industries have been driving economic growth and rising living standards across the globe. As illustrated in Figures 1.1 and 1.2, building a successful manufacturing sector is a prerequisite in national development as manufacturing makes significant contributions not only to individual countries by raising incomes and enabling the construction of modern infrastructure and housing, but also to the world economy by driving global trade, research and development (R&D), and productivity. According to a recent study by the McKinsey Global Institute,1 manufacturing generates 70% of exports and up to 90% of business spending in R&D. Manufacturing, however, is not monolithic as there are fundamental differences across industries. McKinsey segments manufacturing into five broad buckets based on their sources of competitive advantage and their requirements: the segment of global innovation for local markets, which includes chemicals, pharmaceuticals, transport equipment, machinery and appliances, accounts for 34% of the global manufacturing value added in 2010. Regional processing industries, which include food processing, rubber and plastics, fabricated metal products, and printing and publishing, contribute 28% of value added. Energy and resource-intensive commodities, making up 22% of value added, include wood products, paper and pulp, basic metals, and mineral-based products. Global technology industries such as computers and office machinery, semiconductors, medical, precision and optical devices depend on global R&D and production networks to contribute 9% to the global manufacturing value added. Finally, labor intensive tradables such as textile, apparel, furniture, and toys make up 7% of value added. The evolution of these manufacturing segments has resulted in some specialization across different types of economies, creating different centers of gravity (see Figures 1.3 and 1.4) and reshaping the material flows (see Figure 1.5) around the globe.

Figure 1.1 Manufacturing as the locomotive of growth

Source: “Manufacturing the future: The next era of global growth and innovation,” November 2012, McKinsey Global Institute, www.mckinsey.com/mgi. Copyright (c) McKinsey & Company. All rights reserved. Reprinted by permission.

Source: “Manufacturing the future: The next era of global growth and innovation,” November 2012, McKinsey Global Institute, www.mckinsey.com/mgi. Copyright (c) McKinsey & Company. All rights reserved. Reprinted by permission.

Supply chain management (SCM) therefore plays a significant role in maintaining this value-creating global ecosystem. In supporting such sustained economic activity, supply chain costs in developed economies are estimated to be around 10% of the gross domestic product (GDP), surpassing, for example, $1.3 trillion in the United States in 2009. In developing countries, on the other hand, supply chain costs may represent up to 30% of GDP. This is due to both the lower value-added products and services produced by these economies and the higher transaction costs engendered by poorer infrastructure in communication and transportation. Supply chain costs typically consist of:

• 58% for transportation,

• 30% for inventory carrying,

• 8% for warehousing, and

• 4% for logistics administration.

Figure 1.2 Top manufacturers around the globe

Source: “Manufacturing the future: The next era of global growth and innovation,” November 2012, McKinsey Global Institute, www.mckinsey.com/mgi. Copyright (c) McKinsey & Company. All rights reserved. Reprinted by permission.

Source: “Manufacturing the future: The next era of global growth and innovation,” November 2012, McKinsey Global Institute, www.mckinsey.com/mgi. Copyright (c) McKinsey & Company. All rights reserved. Reprinted by permission.

On the other hand, average selling price of a personal computer has been decreasing by 10–15% per year over the past decade. In the automotive industry, a 5% price reduction is not even negotiated between a manufacturer and its suppliers. With margins rapidly shrinking, there is growing pressure on supply chain managers to minimize procurement, production, and distribution costs. Such a focus on cost reduction in SCM has been typical in many industries facing global competition.

While one cannot (and should not) ignore costs, we believe that an exclusive focus on cost minimization is a myopic perspective, which may cause the organization to miss many promising opportunities. In this book, I have therefore chosen to emphasize the enabling role of supply chains in value creation and value capture. In fact, a recent survey of supply chain managers in France by the industry magazine L’Usine Nouvelle has revealed that the responsibilities of these professionals have a scope that largely surpasses cost minimization.2 In particular, supply chain professionals cite among their responsibilities sales forecasting, quality management, strategy development, customer service, internal logistics, external logistics, and systems analysis. In the same survey, supply chain professionals reported that some of their current projects include reduction of product complexity, supply base management, agile manufacturing, production planning, distribution network design, cost analysis, introduction of Electronic Data Interchange (EDI) and Efficient Consumer Response (ECR), change management, and IT systems definition.

Figure 1.3 Global technologies and innovators

Source: “Manufacturing the future: The next era of global growth and innovation,” November 2012, McKinsey Global Institute, www.mckinsey.com/mgi. Copyright (c) McKinsey & Company. All rights reserved. Reprinted by permission.

Source: “Manufacturing the future: The next era of global growth and innovation,” November 2012, McKinsey Global Institute, www.mckinsey.com/mgi. Copyright (c) McKinsey & Company. All rights reserved. Reprinted by permission.

Figure 1.4 Labor-intensive tradables

Source: “Manufacturing the future: The next era of global growth and innovation,” November 2012, McKinsey Global Institute, www.mckinsey.com/mgi. Copyright (c) McKinsey & Company. All rights reserved. Reprinted by permission.

Source: “Manufacturing the future: The next era of global growth and innovation,” November 2012, McKinsey Global Institute, www.mckinsey.com/mgi. Copyright (c) McKinsey & Company. All rights reserved. Reprinted by permission.

Figure 1.5 Global trade routes (1990–2010)

Source: “Manufacturing the future: The next era of global growth and innovation,” November 2012, McKinsey Global Institute, www.mckinsey.com/mgi. Copyright (c) McKinsey & Company. All rights reserved. Reprinted by permission.

Source: “Manufacturing the future: The next era of global growth and innovation,” November 2012, McKinsey Global Institute, www.mckinsey.com/mgi. Copyright (c) McKinsey & Company. All rights reserved. Reprinted by permission.

Both of these lists indicate that the impact of effective SCM is felt beyond mere cost minimization with strategic ramifications for both value creation and value capture through better customer service, reduction of product complexity, and change management. Perhaps a better Profit and Loss (P&L) does indeed mean better production and logistics. We therefore adopt a value-based management perspective for SCM.

1.2 Working definitions

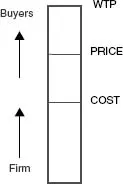

To discuss the role a supply chain plays in value creation and value capture, we first need to define these terms. Scholars in Strategy and Economics relate “value” to the customer’s willingness to pay (WTP), which reflects the benefits perceived by the customer. As illustrated with the “value stick” in Figure 1.6, WTP is the maximum amount that a customer would pay for a firm’s products or services; it is different from price. The value created by a product, a service, or a product–service bundle is then equal to the difference between the customer’s WTP for that offer and the landed cost of the offer. The landed cost includes both procurement costs and internal conversion costs, and the opportunity cost of not being able to undertake some other activity. This definition implicitly captures the fact that a firm can only create value by operating together with its suppliers and customers.

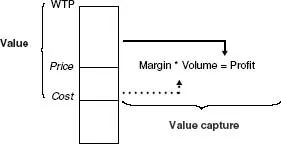

As stated above, the difference between WTP and cost is equal to the value created in a supply chain. While the difference between price and cost determines the margin earned by the firm, the difference between WTP and price (the value captured by the customer or the consumer surplus, as economists would refer to it) drives the sales volume. The product of margin and volume thus yields the profit, the value captured by the firm. Figure 1.7 reflects an interesting trade-off. Value created by a firm is an upper bound on the value it can capture. If the firm sets a higher price (increasing its margin), it may drive down the volume of sales. Alternatively, if the firm lowers its price (reducing its margin), it may increase its sales volume, achieving the same level of profitability. This is why management scholars3 advocate that a firm might adopt either a cost leadership position (low margin and high volume) or a differentiator (niche) position (high margin and low volume) to be profitable. One of the key challenges in SCM is to increase a customer’s WTP without increasing cost. This challenge of mitigating the cost-service trade-off is the main topic of Chapter 4.

Figure 1.6 Defining value as [willingness-to-pay – cost]

Figure 1.7 The interaction between value creation and value capture

Now that we have a conceptual definition of “value” that will be further refined and operationalized in Chapter 2, we turn to the definition of a supply chain. A supply chain is a network consisting of suppliers, manufacturers, distributors, retailers, and customers (Figure 1.8). The network supports three types of flows that require careful planning and close coordination:

(i) material flows, which represent physical product flows from suppliers to customers as well as the reverse flows for product returns, servicing, remanufacturing, and recycling;

(ii) information flows, which represent order transmission and order tracking, coordinating the physical flows; and

(iii) financial flows, which represent credit terms, payment schedules, and consignment arrangements.

Note that all three flows are bi-directional. Traditionally, one used to think that goods and services would go from upstream suppliers to downstream customers through a series of value-adding steps all the way to the final consumer. However, for manufactured products, the manufacturers are now legally accountable for taking back their product at the end of the product’s life cycle and dispose of it in an environmentally responsible fashion.4 We therefore talk about bi-directional or closed-loop supply chains. Similarly, info...

Table of contents

- Cover

- Title

- Copyright

- Contents

- List of Figures and Tables

- Preface

- Introduction: End-to-End Supply Chain Design

- 1 Working Definitions

- 2 Value-Based management: The Guiding Principle for SCM

- 3 Value Creation: Dynamic Supply Chain Design

- 4 Value Creation: Assessing the Cost-Service Trade-Off

- 5 Value Capture: Aligning Supply Chain Partners

- 6 Impact of Technology on SCM: A Brief History of it for SCM

- 7 Service Supply Chains

- 8 Concluding comments

- Appendix

- Notes

- References

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Competitive Supply Chains by Enver Yücesan in PDF and/or ePUB format, as well as other popular books in Business & Business Strategy. We have over one million books available in our catalogue for you to explore.