Environmental sustainability has become increasingly important as it has a fundamental role to achieve economic and social sustainability (Goodland 1995; Goodland and Daly 1996). This book focuses on Industrial Ecology (IE) as a study field and one of its areas—Industrial Symbiosis (IS) and how IE and IS can contribute to environmental sustainability, by promoting closed-loop representations of processes, particularly from an operations management (OM) perspective.

Humans have made an impact on the Earth. We are prosperous and are producing plenty, more than we need. The productivity of the industrial world is increasing constantly and we produce more and faster. We use more natural resources and dispose of more waste to the environment. We are facing natural resource shortages and a high level of pollution and waste. We have been searching for ways to mitigate the situation but much greater effort from all study disciplines and practices is still needed. OM is concerned with producing goods and providing services and improving processes of industrial design, production and delivery. OM also needs to contribute to environmental sustainability . This book explores IE and IS from the OM perspective, but the contents are relevant to all other disciplines in both managerial and technical subject fields, as IE is an interdisciplinary study field and IS supports the achievement of IE’s ultimate goal of developing industrial ecosystems for achieving environmental sustainability.

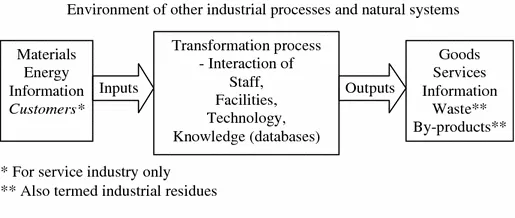

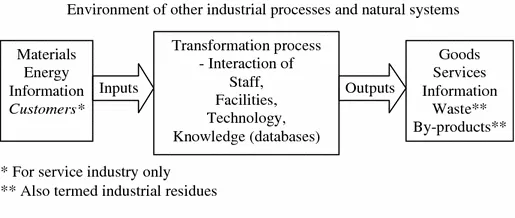

Currently, OM considers a process in a linear transformation and aims to improve the efficiency and effectiveness of this linear transformation process . OM has not purposefully considered where and what types of resources are coming from, and where waste or end-life products should go. Some OM researchers have been exploring environmental sustainability issues in relation to industrial activities. However, environmental sustainability has not been fully embedded in OM, particularly when the process analysis in OM still relies on a linear transformation representation.

In a linear transformation process, staff and facilities provide the capacity to transform raw materials and energy as inputs into finished goods as well as waste or

by-products as outputs (Fig.

1.1). Waste or by-products are normally not considered in the analysis of this

linear transformation process . That is what is still taught in OM. As staff and facilities interacting with each other to provide the capacity of a process, OM focuses on the improvement of staff and facilities and their interactions to be more efficient and effective. However, OM has not paid much attention to industrial waste generated, except for reducing waste along industrial processes to be more efficient. OM focuses on providing goods and services and has not considered

product after-use options , which can also add economic values to a company and its supply chain, as well as environmental values. OM aims to achieve operations objectives of cost, quality, speed, dependability and flexibility, but neglects sustainability and gives limited consideration to sustainability performance, including

environmental sustainability . It seemed acceptable when natural resources were plentiful and waste generated was far less than the Earth’s

carrying capacity . However, this is no longer the case. Industrial systems cannot be sustained for long when natural materials become scarce and waste to nature is more than its carrying capacity - the ability with which nature can decompose waste within a given time and space.

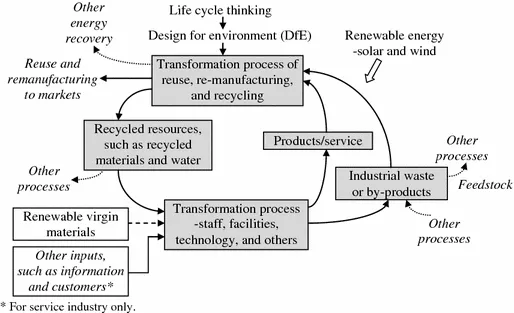

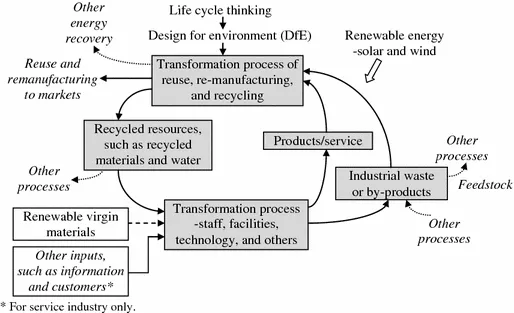

For industrial systems to be sustainable and also the natural world where we are living sustainable, industrial activities need to contribute to the sustainability of the natural world. The

linear transformation thinking needs to be replaced by the

closed-loop system thinking. The idea of closed-loop industrial (eco)systems is not new. Nearly thirty years ago, Frosch and Gallopoulos (

1989) proposed the industrial ecosystem concept, based on the

closed-loop system thinking under which industrial systems mimic the key principles of

biological ecosystems . The waste from one process can be the

feedstock to another (Frosch and Gallopoulos

1989). Achieving this on a large scale requires novel ideas in order for different industries to work together to reduce waste generation as well as increase reuse, remanufacturing and recycling of industrial waste. Reuse, remanufacturing and recycling of after-use products also need to be dramatically increased, with the aid of

design for environment (DfE ).

Recycled materials used in industrial processes still represent a fraction of the total materials used and using the waste from one process as the feedstock to another remains limited. Reuse, remanufacturing and recycling of after-use products are far from achieving their full potential. The

linear transformation process is still considered in OM and much more needs to be done. The closed-loop system thinking should be adopted in OM analyses to support business decision-making (Fig.

1.2).

As a starting point, materials can be categorised as recycled materials—coming from industries or consumers through recycling companies, or renewable virgin materials—coming from nature systems, which are not in shortage in supply and are renewable over an acceptable time period. The proportion of recycled materials over the total materials taken into the circulations of an industrial system needs to be constantly increased towards 100 per cent. We need innovative ideas in order for waste or by-products from one process to be the feedstock to another. We also need innovative designs of products and processes to allow industrial waste and after-use products to be reused, remanufactured or recycled. Management and OM specialists, environmental scientists and material engineers need to work together to propose innovative ideas on reuse, remanufacturing and recycling, as well as using feedstock to other processes.

The

closed-loop system thinking is rooted in IE (Frosch and Gallopoulos

1989; Tibbs

1992), which offers approaches to develop industrial ecosystems which have high level of

closed-loop material exchanges and high

efficiency of energy cascading . IE and IS do not view waste as waste, but resources including energy (Frosch and Gallopoulos

1989; Malcolm and Clift

2002; Tibbs

1992). In this introductory chapter, fundamental concepts in relation to IE and IS are explained leading to the closed-loop system thinking. These concepts include biological, ecological, system and ecosystem. The meaningful combinations of these four concepts with which IE and IS are concerned are biological system, biological ecosystem, industrial system and industrial ecosystem. In order to appreciate IE and IS, these fundamental concepts need to be explored through addressing the following questions.

- 1.

Are all biological systems biological ecosystems?

- 2.

Is there a boundary for a biological ecosystem? If yes, what determines the boundary of a biological ecosystem?

- 3.

What qualifies an industrial system as an industrial ecosystem?

An ecosystem commonly refers to a biological ecosystem, which includes abiotic components which are non-living and environmental elements, such as sunlight, temperature, precipitation, water and moisture, soil and water chemistry etc., as well as biotic components, which are living elements, like plants, animals and humans, and bacteria and fungi (Borman and Liken 1970; Wessells and Hopson 1988; University of Michigan 2008-online teaching materials). These components interact with each other and transform their forms over time and space in an ecosystem or across different ecosystems. A transformation takes place in a material e...