- 255 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Improving Business Performance With Lean, Second Edition

About this book

This book is a concise introduction to the essential concepts and tools used in the Lean method for improving business processes. It constitutes a sufficient toolkit to enable practitioners to quickly start using Lean to improve business processes in their workplace. Alternatively, it can also serve as a textbook in undergraduate or master's programs. Thisbook succinctly describes the benefits of Lean in manufacturing, sales, administration, distribution, health care, and other industries, as well as providing a step-by-step description of how Lean is applied.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER 1

A Brief Introduction to Lean

Have you ever been frustrated because you needed to wait a long time for a good or service to be delivered to you? Do you sometimes feel that companies do not value your time and decrease your personal productivity because they cause you to wait idly while they take their time to serve you? Have you ever had experiences similar to any of the following?

1.You arrived at the doctor’s office on time; you were even a few minutes early. Then, you waited in the waiting room, well past your appointment time, before being called into an examination room. Then, you waited again in the exam room until the doctor finally arrived.

2.You ordered furniture, maybe a sofa or a chair, from a company that makes furniture to order because they could not possibly stock all the upholstery and wood finish alternatives that they offer. Upon purchase, you were informed that delivery would be in 6 to 10 weeks. You were excited about getting the new furniture but were frustrated that you needed to wait so long before receiving it.

3.You needed to order some equipment or repair parts for your company that were vitally needed to keep your operation moving. You waited a long time to receive the parts, and in the meantime, your operation’s performance suffered because you needed to implement workarounds like having employees work extra hours or produce goods of inferior quality.

4.You traveled by air, your plane arrived at its destination, and the pilot taxied the plane to its gate. For two and one-half hours, you looked at the Jetway as you waited for the ground personnel to move the Jetway up to the aircraft. You either missed your next flight or returned home later than otherwise necessary.

5.You traveled by air and arrived at your destination on time, but your bags did not. You wondered how your bags could not have made your connection, which allowed for two hours between flights.

6.You contacted a landscaping or construction company to discuss the possibility of undertaking a home improvement project but found that the contractor took a very long time to return your call. Perhaps your call was never returned. You found yourself wondering how you could trust a company to finish a job on time if they had difficulty simply returning your call.

You are the customer in all these situations, and you might well be upset and frustrated, possibly so much so that you would consider changing doctors, furniture companies, equipment suppliers, airlines, or contractors. The inability of the companies in the preceding examples to provide you with the goods and services you desire in a timely manner is due to these organizations’ inability to execute steps of a procedure in a timely manner. You may wait in the doctor’s office, for one of many reasons, because serving previous patients took a long time. You waited for your furniture because it takes the furniture manufacturer a long time to build the wood frame, apply finish, and then upholster it. Your order for equipment took a long time because it must be manufactured first or because the equipment distributor’s supply is slow or unreliable.

The purpose of the methodology called Lean is to remedy situations like these by reducing the time that it takes to provide customers with what they desire and, therefore, improve customers’ satisfaction with a company’s goods or services. One benefit, among many, of this improved satisfaction is continued and, perhaps, increased patronage from those who are served. We will give examples in Chapter 2 of how making an effort to reduce lead time also improves business performance in other ways, including improved quality, less investment in inventory, less rework, and less warranty expense.

You might have noticed that the previous scenarios were written from the perspective of a customer, and similarly, many authors emphasize that the focus of Lean projects is to enhance customers’ experiences. We will see, however, that while many Lean projects have this external focus on the customers, Lean projects can be focused on providing internal benefit to the company by reducing cost, investment in inventory, and the cost of poor quality.

The History of Lean

Lean was first applied in manufacturing and was called Lean Manufacturing, but more recently, its principles are being applied in healthcare, administrative offices, food service, and other business contexts. To reflect its applicability to these other contexts, Lean Manufacturing is often referred to now as simply Lean. Arguably, Lean grew out of the Toyota Production System (TPS). TPS was developed in post–World War II Japan as the Toyoda family transitioned from manufacturing automatic looms to cars. A lack of resources in postwar Japan required lean operations with the minimum of parts inventory, factory, space, equipment, and labor. While the primary genesis of TPS was the need to maximize the production of automobiles with the minimum possible resources, TPS also contributed to Toyota’s continued quality improvement, which in turn led to the improved competitive position of Toyota vis-à-vis the former Big Three automakers of the United States.

Business Processes

An essential concept that we will use in this book is that of a process. A process is a series of sequential steps that are executed in order to accomplish some goal. For example, if the goal is to build an end table, the steps employed in a furniture factory might be the following:

1.Cut wood parts to appropriate length and width.

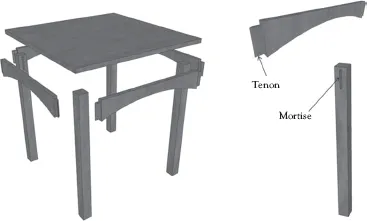

2.Cut mortises and tenons in the wood parts that enable the parts to be joined.

3.Glue pieces together.

4.Sand assembled parts.

5.Apply stain and finish.

It is frequently helpful to display a process graphically using rectangles to indicate each process step, as in Figure 1.1. This process can be associated with the pictorial representation of an end table in Figure 1.2.

Figure 1.1 Process map for furniture manufacture

Figure 1.2 End table construction

Everything accomplished in business can be described as a process as we have done in Figure 1.1 for a furniture-manufacturing process. Whether you work in manufacturing, an administrative process (e.g., human resources, procurement, supplier management, business strategy, business development, accounting), or a service process (e.g., health care, food service, call center), what it takes to accomplish anything can be described as a series of steps, or a process. Processes are often more complex than the one in Figure 1.1 in the sense that they have many more steps, but we will postpone discussion of those situations until later in the book.

Lean can be thought of as a set of tools to improve a process, where the type of improvement we will focus on is to reduce the elapsed time required to execute the process from start to finish, which is called process lead time. Thus Lean is a process improvement methodology. Other process improvement processes exist, most notably Six Sigma. In contrast to Lean, the primary goal of using Six Sigma is to improve quality, to reduce manufacturing defects, or to reduce service and administrative errors. Lean and Six Sigma are currently the two dominant process improvement methodologies, and they are often implemented simultaneously; when that is the case, the approach is called Lean Six Sigma.

Lean and Six Sigma can be further contrasted by comparing the tools used in each of these methodologies. Many of the tools used in Six Sigma rely on the application of statistics to processes to determine what defects are most important to address and what the root causes of the defects are and testing to see if a proposed remedy actually resolves the root causes. Learning the statistics can be difficult for many, and furthermore, collecting the data on which to use the statistical tools can be painstaking. In contrast, people who learn Lean find its tools almost without exception to be simple, intuitive, and easily learned. This is one argument for using Lean before Six Sigma: The tools are more easily learned and applied, thus accelerating the benefit achieved in improving business processes. Another argument for applying Lean first is that it generally results in a simpler process that is more readily evaluated with Six Sigma—indeed, many of the possible root causes of quality errors are likely to be resolved by streamlining the process with Lean before quality issues are explicitly addressed with Six Sigma. The more painstaking and time-consuming Six Sigma tools, then, do not have to be used to find more obvious root causes of defects that have already been sorted out.

While Lean will most frequently be the best set of tools to use first, the ultimate test is to determine which measure of performance is the most important to improve first. If quality improvement is the most important goal, then perhaps Six Sigma should be used first. Conversely, if reducing the time required to execute a process is most important (or one of the many accompanying benefits that we will discuss), then Lean should be used first. Which metrics are most important are determined at the outset of a project, and this is the first step in determining whether Lean or Six Sigma tools are most appropriate. Often, it is appropriate to apply tools from both Lean and Six Sigma. The bottom line is this: Use whatever tools are most appropriate. This book focuses on Lean, however, since it is frequently the methodology that gives the biggest process improvement bang for the buck—that is, the greatest benefit compared with the effort expended.

Returning to our discussion of Lean and TPS, one will find that virtually all of the tools associated with TPS are used in Lean. There is one tool used in Lean, however, that might never be observed in an application of TPS (at least this is the author’s experience). That tool is called value stream mapping, which we describe in Chapter 2.

PART I

Basics of Lean

CHAPTER 2

The Motivation for Implementing Lean

We begin this chapter by establishing the link between process lead time and work-in-process inventory. Specifically, we explain how reducing process lead time also reduces work-in-process inventory. While reducing work-in-process is a fundamental goal of some Lean projects, it is not the main goal of all projects. So in the remainder of the chapter we document how reducing lead time improves many other important business metrics in various industries.

Lead Time and Work-in-Process

We begin with an intuitive example that serves as an analogy to the business contexts that we will subsequently discuss. This analogy considers a pipe that carries water, which might be the water that fills a swimming pool or water used in making paper or another manufactured material. Specifically, consider two such pipes as shown in Figure 2.1. Both pipes have identical diameters and carry water at the same flow rate (gallons per minute). Since they have the same diameters and flow rates, we know that a drop of water flowing down the center of the pipe would have the same average velocity in both pipes. Thus the time to traverse the longer pipe, intuitively, takes a greater amount of time than a drop flowing down the shorter pipe.

Figure 2.1 Two pipes for carrying water

Now, we ask the question, which pipe has more wat...

Table of contents

- Cover

- Halftitle

- Title

- Abstract

- Contents

- Acknowledgments

- About This Book

- Chapter 1 A Brief Introduction to Lean

- Part I Basics of Lean

- Part II Lean Tools

- Part III Implementing Lean

- Part IV Practice

- Appendix: The Effect of Variation on Kanban Systems

- Notes

- References

- Index

- Adpage

- Backcover

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Improving Business Performance With Lean, Second Edition by James R. Bradley in PDF and/or ePUB format, as well as other popular books in Business & Operations. We have over one million books available in our catalogue for you to explore.