![]()

IN 1998, a ban on the cultivation of industrial hemp in Canada was ended with the passing of the Industrial Hemp Regulations. Shortly thereafter, I received a call from a neighboring farmer, Grant Moorcroft. He was aware that I had been building with straw bales for a few years, and he wanted me to come and check out the bales of hemp straw he had made from his first hemp crop and see if they would be useful as building bales.

As it turned out, the hemp straw bales (made from the stalks of hemp grown for seed production) made excellent building bales, and I went on to use them on many projects.

At that same time, the Internet was starting to play an important role in my sustainable building research, and high on the list of interesting information I was finding online was a material called “hempcrete.” All of the early information I could find about hempcrete was from France, and from what I could discern across the language barrier, this material was a mixture of chopped hemp stalks and lime. The recipes were all proprietary, so there was little else to discern other than the basic materials.

Armed with this minimal amount of information, Grant and I began chopping up his hemp stalks and playing with hempcrete recipes. Right from the very first experiments, I was excited and enthusiastic about this material. Our results provided a material that was relatively low-density and would obviously have good insulation properties. At the same time, the material had a body and integrity to it that allowed it to be formed into bricks and blocks with some structural properties. The material could be sculpted and formed. It made an excellent substrate for plaster. I was intrigued.

Early on, I started burying some of the sample blocks to see how they would react to constant exposure to moisture. After one year, I dug out the first buried samples and was impressed to find that there had been no noticeable deterioration. I put them back in the ground, and checked them again at years two and three with the same result, suggesting that this bio-fiber insulation provides resistance to moisture in a way that far exceeds other bio-fiber insulations — very important in the northern climate where I build.

I first used hempcrete in a code-approved building in 2005, casting hempcrete insulated window header sections in a straw bale building and creating one interior infill wall. By 2008, I was using hempcrete to cast fully insulated frame walls, to create sub-slab insulation and to insulate around windows. Many subsequent projects included hempcrete in one form or another.

There was a hiatus in my use of hempcrete for a few years, because Grant decided to stop growing hemp. After a brief period of enthusiastic adoption by farmers in Ontario, the lack of markets for hemp materials in our region led many farmers to cease production. Unfortunately, this situation exists today. It has meant that an important and valuable regional building material cannot be acquired locally. I look forward to the day when this situation is reversed and local farmers once again plant, cultivate, process and sell hemp products locally.

Hempcrete has remained an important part of my building practice, despite having to import the hemp material from another region of Canada. As the European experience has shown, hempcrete insulation has the potential to take an important role in greening our built environment. Academic and government interest in hemp building products has created a healthy market for European hempcrete in just a decade. Since the early work documented in the first book about hempcrete, Building with Hemp by Steve Allin in 2005, the number of hempcrete buildings in the UK, France, Germany and other European countries has grown exponentially. Meanwhile, in North America only a small handful of dedicated builders work on developing methods and materials here.

The main reason for the large gap in hemp-crete development between Europe and North America is the continued ban on industrial hemp farming in the U.S. The failure of legalized hemp farming in Canada to result in the creation of significant processing facilities shows that without legalization and the development of markets in the U.S., any use of hemp materials on this continent will remain a fringe activity. At the time of writing, there are some positive indications that American federal and state government are moving to relax restrictions on industrial hemp farming. It is now imaginable that a critical mass of farmers and production facilities in the U.S. is possible within a matter of years.

This book is a hopeful precursor to the wide availability of hempcrete materials in North America. The materials and techniques presented here are even now feasible, affordable and practical. The creation of new material sources will help hempcrete in North America follow the positive trajectory of the material in Europe. I encourage forward-looking green builders to jump on board now!

![]()

HEMPCRETE (or hemp-lime, as it’s commonly called in Europe) is a promising building insulation material. It is also the subject of more hype and hyperbole than any other sustainable building material. Proponents of hemp-based products tend toward unsupported or exaggerated claims of performance and planetary benefit with Websites that make the material seem miraculous.

In truth, hempcrete is simply a very good building insulation material, and there are plenty of compelling reasons to consider using it. It makes an excellent addition to the sustainable builder’s “tool kit” of more people- and planet-friendly building solutions. Hempcrete alone will not save the planet, but it will provide an excellent insulation material to a project with the right criteria and context. This book is intended to highlight both the advantages and disadvantages of hempcrete and provide potential users with reliable and tested information.

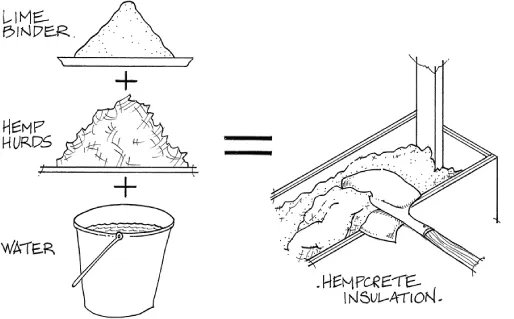

What Is Hempcrete?

Hempcrete is a unique building material, being a composite of a bio-fiber (hemp hurd or shiv) and a mineral binder (lime). These ingredients are blended together with water, and the moistened binder coats all the particles of hemp shiv. A chemical reaction occurs between the lime binder and the water, resulting in the binder setting and gluing the hurd particles together. Generically, it could be called “bonded cellulose insulation.”

When the binder is set and cured and any additional water has dried out of the mixture, the resulting material is hempcrete. Unlike many construction composites (such as concrete, mortar and plaster), the binder portion in hempcrete is not intended to fill all the voids between the hemp particles, but only to coat the particles and cause them to adhere to one another where they touch. A hempcrete mix typically has a high percentage of void space in the final mixture.

Hempcrete has a range of desirable thermal, structural and moisture-handling properties that make for an excellent building insulation material. Depending on the mix variables described in this book, hempcrete can be used as roof, wall and/or slab insulation.

Accounting for the variables

Any discussion of hempcrete is complicated by the fact that all three elements in the bio-composite can have a range of types and characteristics, and can be added to the mix in varying ratios.

Hemp hurd

The hemp hurd is the woody core of the hemp plant. It is typically sourced from hemp fiber producers after the valuable hemp fiber has been stripped from the outside of the hemp stalk, leaving the hurd as a by-product.

Variables in the hurd portion of the hemp-crete composite include size and grading of the hurd and volume and length of hemp fiber.

Desirable properties for hurd are given in the Material Specifications chapter of this book.

Lime binder

Lime has been an important binder in construction for thousands of years, largely in mortar and plaster recipes. There are different types and grades of lime, and there are various additives that may be included in the binder ratios. These variables will affect the setting time, strength and durability of the hempcrete mixture. There are several brands of manufactured lime binders made specifically for use in hempcrete, and there are recipes for creating lime binder from separate ingredients. The specific qualities that are ideal for a lime binder for hempcrete are discussed in the Material Specifications chapter.

Water

The volume of water added to a hempcrete mixture will have a dramatic effect on the results, even if the hurd and lime variables are controlled. Hemp hurd is extremely porous, capable of absorbing a volume of water that is much larger than what is required for a good hempcrete mixture. Too much water in a mixture can result in higher density, issues with setting for the lime binder, and excessively long drying times for the hempcrete.

Placement and tamping

The final — and also critical — variable is the placement of hempcrete into the building. In wall and floor applications, the material requires some manual tamping in order to ensure that the mix is well bonded and has integrity. However, the amount of tamping can have a major impact on the density of the final material, even if all the mix ratios are identical. Variations in density can have a large impact on thermal performance, so this is an important variable to try to control. This will be covered in the Construction Procedure chapter of this book.

Limitations in quantifying hempcrete

A great deal of this book is intended to help builders find the ideal ingredients and mixtures in order to be able to use hempcrete successfully. But the variability in the formulations and ingredients make it difficult to make blanket generalizations about the performance parameters of hempcrete, especially compared to manufactured insulation products that come from a factory with little or no variation.

Throughout this book, a concerted effort has been made to use relevant testing data, based on knowledge of the variables, and pointing out where the testing data is incomplete or inconclusive.

Why Hempcrete?

The bu...