- 218 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Textile Engineering

About this book

Currently, most of the textile industry and textile institutions are located in South Asia. The textile industry leads to the development of clothing from fibres, yarns, and fabrics. The industry is growing in this area as it has already been shifted from Europe and is being shifting from China. As the textile industry is growing, many new textile intuitions are being established to provide for quality textile education. This introductory level textbooks is geared towars them.

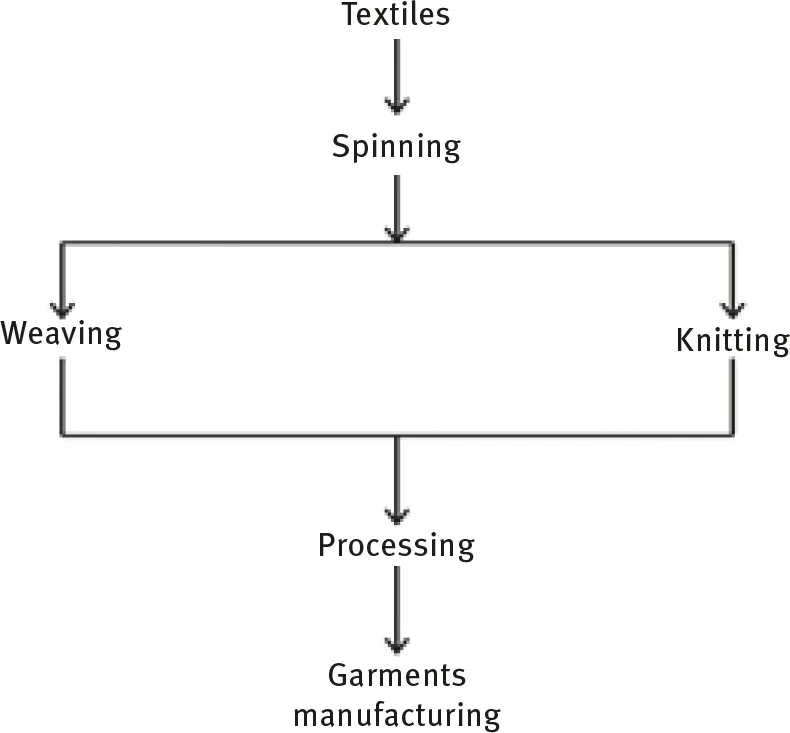

This book will provide all necessary information from fibres to fabrics and their conversion to clothing. The importance of textiles in the current era along with the raw materials needed for the textiles are given. After that, it is explained how the yarn is made from fibres. Then the fabrics manufacturing, the printing and dyeing of textiles and the conversion of fabrics into the garments is discussed. Also, the testing of fibres, yarns and fabrics along with the description of technical textiles is mentioned.

This book is beneficial for all readers who are going to start their career in textiles or are going to start the engineering degree in textiles. The present book is designed for the first year students (especially for the National Textile University Faisalabad) of textile engineering.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1Introduction

1.1What is Textile?

1.2History of Textiles

1.3Status of Textiles in World Exports

| Period | Evolution of dyeing material and processes |

| 3500 BC | Dyeing Practised in China but solid evidence is missing. |

| 2500 BC | Religious and social records suggest that Indians used to dye silk and brocades. |

| 715 BC | Wool dyeing established as craft in Rome. |

| 327 BC | Alexander the Great mentions “beautiful printed cottons” in India. |

| 55 BC | Romans found painted people “picti” in Gaul dyeing themselves with Woad. |

| 2nd and 3rd AD | Roman graves found with madder- and indigo-dyed textiles, replacing the old |

| Centuries | Imperial Purple. |

| 273 AD | Emperor Aurelian refused to let his wife buy a purpura-dyed silk garment. It cost its weight in gold. |

| 700s | A Chinese manuscript mentions dyeing with wax resist technique. |

| 925 | The Wool Dyers’ Guilds first initiated in Germany. |

| 1188 | The first mention of Guilds for Dyers in London. |

| 1197 | King John (of Magna Carta fame) persuaded Parliament to regulate dyeing of woolens to protect the public from poor quality goods. |

| 1212 | The city of Florence had over 200 dyers, fullers and tailors. A directory of weavers and spinners was published as well. |

| 1290 | The only blue dye of the period, Woad, began to be raised extensively in Germany. |

| 1321 | Brazilwood was first mentioned as a dye, source from East Indies and India. |

| 1472 | Edward IV incorporated the Dyers’ Company of London. |

| 1507 | France, Holland and Germany begin the cultivation of dye plants as an industry. |

| 1614 | Dyeing cloth “in the wood” was introduced in England: logwood, fustic, etc. |

| 1689 | The first calico printworks was begun in Germany at Augsburg and was later to grow into a large industry. |

| 1745 | Indigo begins to be grown in England, after the Revolu... |

Table of contents

- Cover

- Also of interest

- Title Page

- Copyright

- Foreword

- Contents

- Front Matter 2

- 1 Introduction

- 2 Textile Raw Materials

- 3 Yarn Manufacturing

- 4 Fabric Manufacturing

- 5 Textile Processing

- 6 Clothing

- 7 Technical Textiles

- 8 Textile Testing

- 9 Disposal and Recycling of Textiles

- 10 Quality Control and Quality Assurance

- 11 Computer Applications in Textiles

- Index

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app