![]()

CHAPTER 1

The Supply Chain Operations Reference Model

The Cross-Industry Standard for Supply Chain Peter Bolstorff was introduced to the Supply Chain Operations Reference (SCOR) model in the fall of 1996 when he became part of a newly formed corporate “internal consulting” team for Imation, which had just been spun off from 3M. He’s been using the SCOR model in supply chain improvement project work ever since. He was a delegate at the first conference of the Supply Chain Council, and has remained active in the Council, involved in the process of improving SCOR and teaching others how to use it. In fact, the Supply Chain Council adopted Supply Chain Excellence as the core text for its SCOR Project implementation workshops globally.

So he’s heard all the questions. Among those most frequently asked are these: What is the Supply Chain Council? What is SCOR? How do I use SCOR? What is the value to my organization? How do I learn more about SCOR?

The Supply Chain Council

The Supply Chain Council (www.supply-chain.org) is an independent not-for-profit corporation formed in 1996 as a grassroots initiative to develop a supply chain process model. Among those involved at the start were individuals from such organizations as Bayer; Compaq; Procter & Gamble; Lockheed Martin; Nortel; Rockwell Semiconductor; Texas Instruments; 3M; Cargill; Pittiglio, Rabin, Todd & McGrath (PRTM); and AMR Research, Inc. In all, 69 of the world’s leading companies participated in the council’s founding. Its mission today is to perpetuate use of the SCOR model through technical development, research, education, and conference events. By the end of 2010, the council’s technical community had released nine subsequent versions of SCOR, providing updates to process elements, metrics, practices, and tools. SCOR 10.0 also incorporates a “People” standard for describing skills required to perform tasks and manage processes.

The council has about 1,000 corporate members worldwide, with chapters in Australia/New Zealand, Latin America, Greater China, Europe, Japan, Southeast Asia, and South Africa. Membership is open to any organization interested in applying and advancing principles of supply chain management. In 2010 there were four tiers of membership: global, standard, small business, and nonprofit.

The SCOR Framework

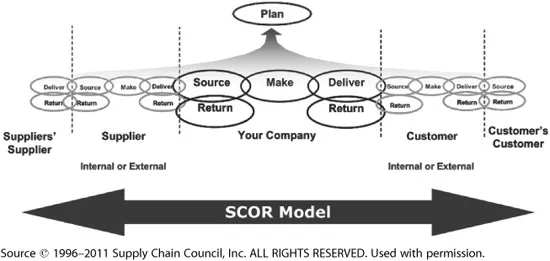

SCOR combines elements of business process engineering, metrics, benchmarking, leading practices, and people skills into a single framework. Under SCOR, supply chain management is defined as the integrated processes of PLAN, SOURCE, MAKE, DELIVER, and RETURN—from the supplier’s supplier to the customer’s customer (Figure 1-1). The Supply Chain Council Web site, www.supply-chain.org, has an online overview of the model that can be viewed both by members and nonmembers.

Here’s what’s included in each of the SCOR process elements:

PLAN: Assess supply resources; aggregate and prioritize demand requirements; plan inventory for distribution, production, and material requirements; and plan rough-cut capacity for all products and all channels.

Figure 1-1. The SCOR Framework.

SOURCE: Obtain, receive, inspect, hold, issue, and authorize payment for raw materials and purchased finished goods.

MAKE: Request and receive material; manufacture and test product; package, hold, and/or release product.

DELIVER: Execute order management processes; generate quotations; configure product; create and maintain customer database; maintain product/price database; manage accounts receivable, credits, collections, and invoicing; execute warehouse processes including pick, pack, and configure; create customer-specific packaging/labeling; consolidate orders; ship products; manage transportation processes and import/export; and verify performance.

RETURN: Defective, warranty, and excess return processing, including authorization, scheduling, inspection, transfer, warranty administration, receiving and verifying defective products, disposition, and replacement.

In addition, SCOR includes a series of ENABLE elements for each of the processes. These processes focus on management around performance, information, policy, inventory strategy, capital assets, transportation, physical logistic network, regulatory, and other management processes to enable the planning and execution of supply chain activities.

SCOR spans all customer, product, and market interactions surrounding sales orders, purchase orders, work orders, return authorizations, forecasts, and replenishment orders. It also encompasses material movements of raw material, work-in-process, finished goods, and return goods.

The SCOR model includes three levels of process detail. In practice, Level 1 defines the number of supply chains, how their performance is measured, and necessary competitive requirements. Level 2 defines the configuration of planning and execution strategies in material flow, using standard categories such as make-to-stock, make-to-order, and engineer-to-order. Level 3 defines the business processes and system functionality used to transact sales orders, purchase orders, work orders, return authorizations, replenishment orders, and forecasts. Level 4 process detail is not contained in SCOR but must be defined to implement improvements and manage processes. Advanced users of the framework have defined process detail as far as Level 5, software configuration detail.

Value Chain Processes

In 2004, the Supply Chain Council introduced two new frameworks that help piece together more of the detailed mosaic of enterprise value chains (Figure 1-2). The Customer Chain Operations Reference (CCOR 1.0) model defines the customer part of the value chain as the integration of PLAN, RELATE, SELL, CONTRACT, SERVICE, and ENABLE processes.

The Design Chain Operations Reference (DCOR 2.0) model defines the design part of the Value Chain as the integration of PLAN, RESEARCH, DESIGN, INTEGRATE, AMEND, and ENABLE processes.

Figure 1-2. Value Chain frameworks.

Chapter 19 will discuss how these process models can be used with SCOR to drive overall value chain performance improvement.

Using SCOR to Drive Supply Chain Improvement

For all its power and flexibility, the SCOR model is still essentially a series of definitions for processes, metrics, and leading practices. Simply having the “dictionary” doesn’t do any good for a business. To use SCOR, it is necessary to add effective change management, problem-solving techniques, project management discipline, and business-process engineering techniques. Supply Chain Excellence is a handbook on how to use SCOR with a refined five-step formula that has been tested and proven in the course of more than 100 projects on six continents, in ten languages and with six enterprise software systems, incorporating Lean and Six Sigma, growing sales and profits, improving inventory turns, increasing productivity, and making customers happier.

The phases of the Supply Chain Excellence approach, as detailed in this third edition of the book, have been refined to support global projects in which units operate more like small business. The refinements have helped reduce the resource and time requirements to develop a project list by 50 percent and have eliminated non-value-added analysis by shifting material, work, and information flow analysis to implementation. We use the same analytical tools but focus only on the scope of each project. The refined steps are as follows:

1. Build organizational support

2. Define project scope

3. Analyze performance

4. Develop project portfolio

5. Implement projects

Build Organizational Support

Chapter 2 examines how to build organizational support for a SCOR project. The chapter explores four important roles: the “evangelist,” the person in the company who has the passion, experience, and talent to lead a supply chain project; the “active executive,” the individual who is accountable as sponsor of a supply chain project through modeling, influence, and leadership; the “core steering team,” which has the champion role to review and approve recommendations and ultimately lead the implementation efforts; and the “design team,” which analyzes the supply chain from end to end and assembles recommendations for change.

Define Project Scope

Chapter 3 helps to define and prioritize the organization’s supply chains using a combination of data and strategic assessment. One of the primary outcomes from the discovery step is a Project Charter, which helps define a project’s scope, approach, objectives, schedule, milestones, deliverables, budget, organization, measures of successes, and communication plan.

Analyze Performance

The analysis stage (Chapters 4 through 7) is where the metrics are defined, data are collected, defects are analyzed, benchmarks are tallied, and performance gaps are calculated. Frequently used SCOR metrics include cash-to-cash cycle time, inventory days of supply, perfect order fulfillment, order fulfillment cycle time, total supply chain management cost, and upside supply chain flexibility. This phase also helps the team to prioritize and balance customer metrics with internal-facing metrics: delivery, reliability, flexibility/responsiveness, cost, and assets.

Develop Project Portfolio

Chapters 8 through 10 describe the analytical steps required to identify a company’s preliminary project list. Tasks in this phase include further analysis of metric defects; conducting a brainstorming session; using problem-solving tools such as fishbone diagrams, run charts, and affinity grouping; and working with finance to validate both financial and customer-service improvement commitments.

Implement Projects

Chapters 11 through 18 describe the thirteen steps necessary to implement a project identified in the portfolio. Analytic techniques for...