![]()

1 TOOLS OF THE TRADE

WHEN MY COMPANY WAS FORMED in 1985, it was to take exploit patents acquired from a West German engineer. Originally called Cavity Lock Systems Ltd, it had been manufacturing and producing stainless steel cavity wall ties used to overcome the endemic problem in the United Kingdom of corrosion in the mild steel ones.

Wall ties were used from the early nineteenth century to connect single-brick walls together to form a double external wall to prevent moisture passing into the interior of the structure. However, because of inadequate knowledge at that time of corrosion of metals, and particularly of the effect of the black ash mortar used throughout the United Kingdom on bare or galvanized metals, the ties started to corrode, eventually causing the outer skin of the cavity wall to become structurally unstable. The ties could expand to up to seven times their size, forcing the exterior wall to crack and lift, in some cases up to 100 mm, on a traditional semi-detached house. The tell-tale horizontal cracking at every fifth course in the exterior brickwork walls was a sure sign of this failure. Finding a remedy was always going to be difficult. Should the whole tie be removed, or merely bent back into the cavity to protect the external wall from further damage, or would it have to be replaced with a new stainless steel tie?

It was because of the many practical problems of retrofitting replacement wall ties into old structures that I set about looking for a better, more professional solution than the current mechanical expanding stainless steel sleeves or resin injection methods, which caused numerous problems with weak or friable substrates. In my view, the whole tie should be removed and replaced with a new one fitted into both internal and external wall skins.

During my explorations of the industry I came across a Belgian sales engineer looking for a United Kingdom partner for a German inventor, one with experience in using a fabric-socked anchor to solve problems of fixings in the hollow-pot clay blocks used extensively on the Continent. Many of the external walls of West German buildings were constructed in this way, and he had developed some promising ideas using a system that was ideally suited to the problems encountered in repairing or upgrading by adding a new outer wall cladding. Working together, we were able to provide a fabric-socked solution to many of the problems in restoration associated with structural defects, both in hollow-pot and in solid structures.

The tell-tale horizontal cracking in the external rendering indicating wall-tie corrosion.

Corroded wall-ties in an advanced state of corrosion. These are over-cored and removed using diamond drill techniques and replaced with a new stainless steel wall-tie.

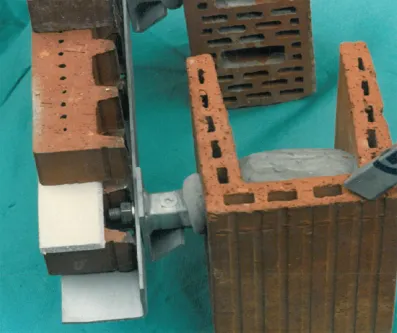

Cavity wall construction built to prevent moisture entering the dwellings.

The first use of the sock technology to overcome the problem of fixing new facades to hollow-pot construction.

It was this simple concept that set us off, and we proceeded to develop and fine-tune the idea into a new and more complete way of strengthening structures. After several years of working with these ideas, I decided to acquire the original basic patents and develop the system to encompass a greater range of products and the structures that could be reinforced. It was soon after buying the patents that I decided to create a strong brand name using the current name of the product called Cintec, an acronym for consolidated injection technology.

The company has grown since then with offices in Canada, America, Australia, India and Egypt. It has won many awards and citations for its achievements over the years, in particular the Queen’s Award for Innovation in 2002 for strengthening masonry and stone arch bridges. In 2014, I received the Chartered Institute of Builders Award for the outstanding international project for the year for the work on restoring the ceiling of the burial chamber in the Step Pyramid. This monument is an iconic structure dating from 2700 bc, and it is the earliest high-rise stone building in the world.

Whilst the device we developed looks very simple, it is ingenious in concept: not merely a product but the culmination of engineering know-how and the skills with which we can design a complete system to match the requirements of strengthening individual structures.

DESIGN CONSIDERATIONS

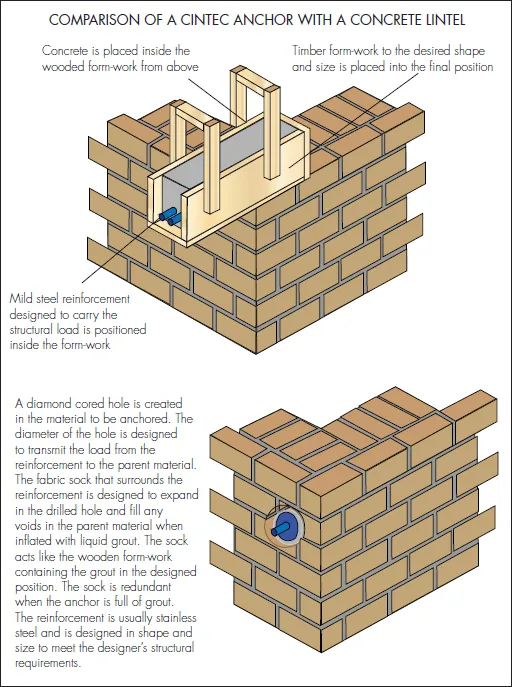

The best way to describe the use of the Cintec anchor is to consider how you would place a reinforcement member into an existing building. Imagine you wanted to provide a reinforced concrete lintel into an existing building. Forget the problem of opening up an area to accommodate the lintel and all the associated support work needed, but merely consider making a wooden box the overall size of the lintel, having calculated the amount of steel reinforcing you require, and place this into the box in the correct position. You then somehow pour concrete into the box until it is full to the top.

Think of our system as a lintel, but instead of the wooden box we have a much smaller fabric tubular sock to replace the wooden box, and accordingly a hole to accommodate the sock is drilled, usually with diamond drilling techniques, into the substrate. Although a large opening is needed when we use a wooden box, we do not have to create a large opening needing struts and props.

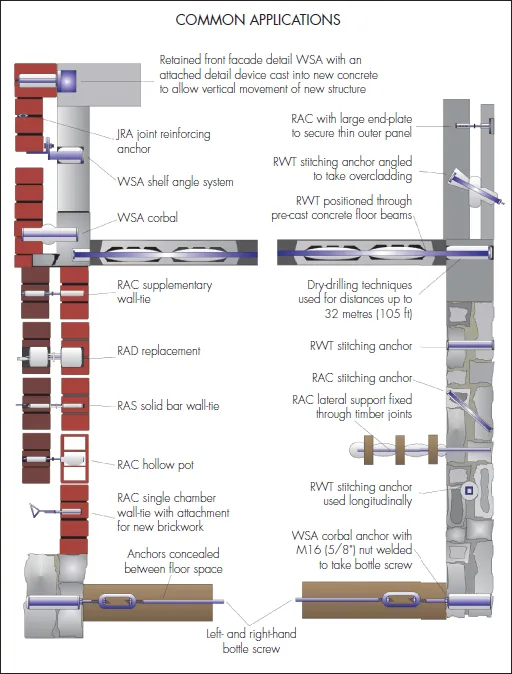

Some typical bespoke remedial applications used in stabilisation and repairs.

Having calculated the main reinforcing bar for the application we are able to provide a complete product that, once we have created the hole, can be made to fit exactly.

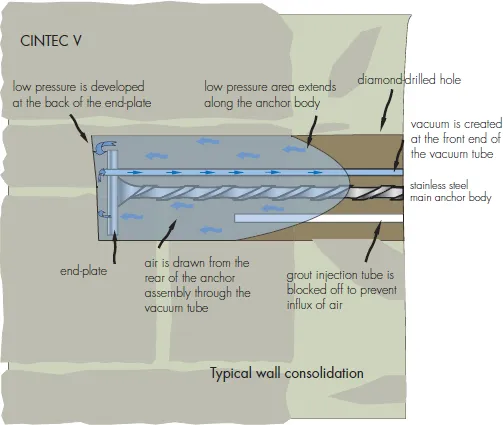

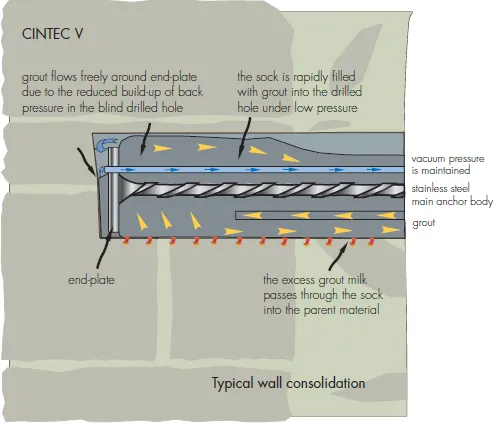

The entire assembly is placed in the drilled hole and then a suitable non-shrink grout is pumped from a pressure pot, through injection tubes to the rear of the assembly, filling it from back to front. The grout is placed under pressure and fills the entire assembly. A new development has taken place recently using not only a pressure pot to pump grout into the anchor but also to develop a vacuum at the internal end of the reinforcement. This gives greater control in anchoring the reinforcement, and also a positive feedback to the installer, indicating how the anchor is inflating, which is essential when filling an anchor above the horizontal plane. Once the reinforcement is installed, it remains dormant in the wall until it is required to work structurally.

Whilst the analogy of the lintel mirrors the way the anchor actually works, there are numerous other structural solutions to other, more complex structural problems.

An illustration of how the new Cintec vacuum system is used to control grout injection in the anchor assembly. This is achieved by creating a low negative pressure at the extreme end of the assembly as grout is injected into the anchor.

This shows the advantage of the vacuum system, particularly for installation of vertical positioned anchors.

Very often conservationists refer to the problem that the reinforcement is too rigid and demand that the grout must be lime-based in keeping with the original structure. Would one take the risk of having a lime-based lintel over one’s head? The material and design must be fit for purpose. The original construction was probably built of local materials and needed to be flexible. Structural anchoring and repairs need to be able to mobilize the forces required to lock the structure together. If the designer needs steel reinforcement, this must be connected to the fabric of the structure with a grout that i...