![]()

CHAPTER 1

Supply Chain Management Concepts

SCM Definition

The Council of SCM Professionals (CSCMP) defines SCM as follows:

SCM encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. Importantly, SCM also includes coordination and collaboration with channel partners, which can be suppliers, intermediaries, third-party service providers, and customers. In essence, SCM integrates supply and demand management within and across companies. SCM is an integrating function with primary responsibility for linking major business functions and business processes within and across companies into a cohesive and high-performing business model. It includes all of the logistics management activities noted above, as well as manufacturing operations, and it drives coordination of processes and activities with and across marketing, sales, product design, finance, and information technology.

—CSCMP*

Introduction

SCM is not a new concept about technology, software, or business systems. In light of the important problems and potential opportunities created by globalization, the high demands on companies to establish systematic relationships with stakeholders are prominent. The tremendous pressures from customer satisfaction, cost cuts, and fast services are essential to shift from the traditional concepts on logistics or marketing channels to a comprehensive SCM system. Back in 1915, Arch Wilkinson Shaw† was hired by Harvard University to teach business policy, reorganize curriculum, and start the school’s Bureau of Business Research. He was the first one to analyze market distribution issues. He published in August 1912, in the Quarterly Journal of Economics, an article titled “Some Problems in Distribution Market,” which became a seminal article in marketing studies. The business book he wrote and published by Harvard University Press was later considered the world’s first textbook on SCM.

“The most pressing problem of the business man today, ‘Shaw wrote,’ is systematically to study distribution,” by which he meant both physically supplying a product and creating demand for it among consumers via marketing.1

More than 100 years later, businesses in every industry are working harder to source raw materials globally, manufacture products with lower cost, operate processes more efficiently, move products faster, and better satisfy their customers.

To face the oncoming era of globalization, companies have to accept these challenges. They must take chances to deal with all kinds of tasks by using various strategies and approaches. As Shaw wrote, “Systematic study must replace experiences and empirical rules.”[Ibid] This is a precognition, which has forecasted the importance of SCM.

In the global economy, some businesses are increasingly forced to shift from multinational to becoming transnational.2 Businesses that can locate their suppliers diversely, execute manufacturing operations efficiently, motivate their employees’ loyalty capably, transport the goods in a timely fashion, and service their customers satisfactorily are going to be the winners in the present fast-expanding economy.

Each element listed previously is essential to a company’s success. However, many companies fail because they do not recognize SCM as an essential contributor for the profitable accomplishment of their business development.

Air Canada, for instance, had many long-term problems related to its operations, financial management, networking, pricing, union issues, and customer service. Even though other airlines were also struggling to cope with the travel slump caused by the September 11, 2001 attacks, the war on Iraq, and stiff competition at that time, Air Canada was doing poorly while Singapore Airlines was doing well.3

Therefore, to figure out how to improve a business core advantage and to increase its strategic competitiveness, SCM is becoming more critical, especially in a global business setting.

SCM Revisited

According to the Canadian Supply Chain Sector Council,‡ SCM encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. Importantly, it also includes coordination and collaboration with channel partners, which can be suppliers, intermediaries, third-party service providers, and customers. In essence, SCM integrates supply and demand management within and across companies.

SCM as an integrating function has a primary responsibility for linking major business functions and business processes within and across companies into a cohesive and high-performing business model. SCM includes all the logistics management activities noted earlier as well as manufacturing operations, and it drives coordination of processes and activities with and across marketing, sales, product design, finance, and information technology.§

What Is a Supply Chain?

A supply chain is the sequence of organizations, their facilities, functions, and activities that are involved in producing and delivering a product or service. The sequence begins with the suppliers of raw materials and extends all the way to the final customers as end-users of the product or service provided. Facilities include factories, processing centers, warehouses, distribution centers, retail outlets, and offices. Functions and activities include forecasting, purchasing, inventory management, information management, quality assurance, scheduling, production, distribution, delivery, and customer service.4

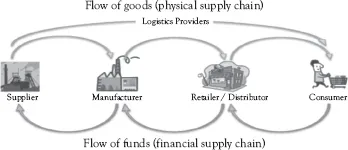

Figure 1.1 Flow in a supply chain

Source: CTMfile.com

Figure 1.1 illustrates the physical information flow between various entities in a supply chain.

Dr. Douglas M. Lambert defines SCM as “The integration of key business processes from the end user through original suppliers that provides products, services, and information that add value for customers and other stakeholders.”5

Business Practice Management

Business practice management (BPM) is closely related to SCM. The whole approach to BPM was systematically introduced in the 1980s. BPM is a business strategy intended to help companies overcome the challenges of fluctuating markets and adapt to the ever-evolving needs of consumers. BPM operations are associated with various scientific researches and technological advances, which can manage effectively the supplier’s selection, manufacturing process, transportation arrangement, logistical availabilities, and customer satisfaction issues. BPM also involves a variety of activities on sourcing raw materials, manufacturing products, scheduling shipment, warehousing and distribution, quality control, and customer service, all part of a series of complicated systems, in which every step in their links must be executed with adequate delivery, quality, coordination, and performance at the right time, the right place, and the right cost.

Since the 1990s, when technology started to drive the marketplace and the informational revolution speeded-up business, companies in every industry were encountering important challenges about how they could manage their issues with superior competitiveness under fierce competition. Many of these companies, especially international enterprises, began to pay more attention to their business strategies to compete against their rivals for business development.

They found that to beat their counterparts, it was not enough to improve only their efficiencies and quality within their organizations. They also had to cooperate with their partners as a single entity and develop a comprehensive supply chain, which could assist them in becoming more competitive in the marketplace. The understanding and practice of SCM has become an essential prerequisite for staying competitive and boosting business profitably and market share.6

In current business settings, SCM has been identified as a comprehensive integration of different forms of operational management. If a business were to operate without an effective SCM practice, that business would be vulnerable to competition, which might lead to a reduction of effectiveness, sustainability, and profitability.

The Digital Revolution

The Digital Revolution representing the change from mechanical and analog electronic technology to digital electronics began anywhere from the late 1950s to the late 1970s with the adoption and proliferation of digital computers and digital record-keeping that continues to the present day.

In 1994, Netscape was the first company attempting to capitalize on the newly introduced World Wide Web (WWW).¶ The release in 1995 of version 1.0 of the Internet Explorer by Microsoft, introduced in earnest the WWW to the business world. Many compan...